Seed crystal type early strength agent and preparation method thereof

A technology of accelerator and seed crystal, which is applied in the field of seed crystal accelerator and its preparation, can solve the problems of poor low-temperature early-strength effect, limited material source, high durability risk, etc., and realize waste utilization, process Simple, low-equipment-required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

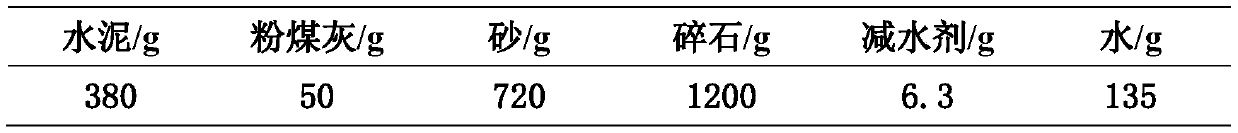

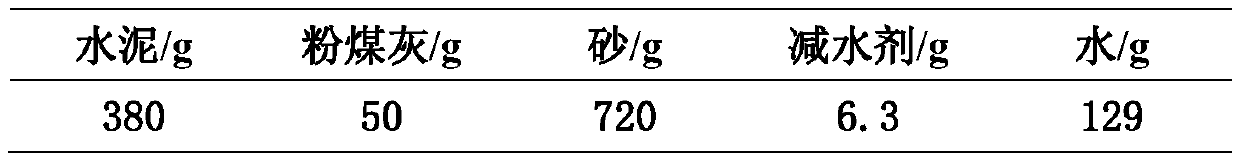

Examples

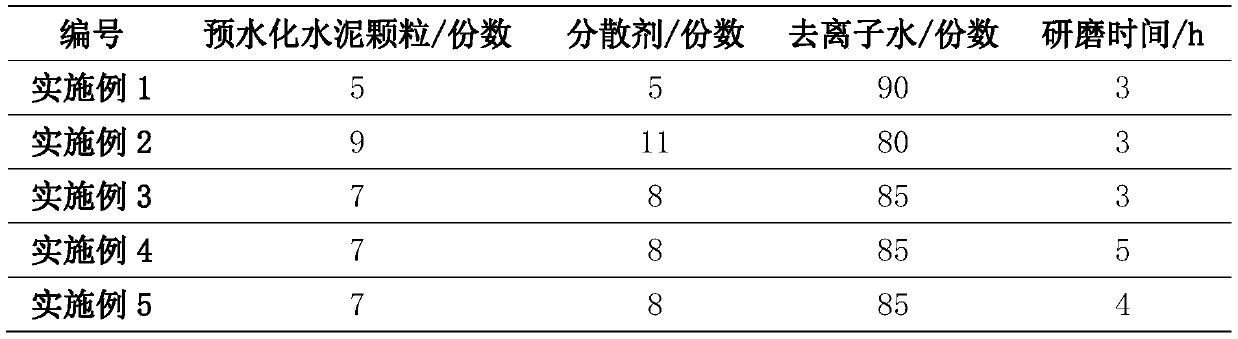

Embodiment 1

[0037] Embodiment 1 provides a kind of seed crystal type early strength agent, as shown in table 3 (table 3 is the preparation formula and parameter information table of each embodiment seed crystal type early strength agent), the dispersant described in table 3 is Powder polycarboxylate water-reducer (the dispersants used in Examples 1-5 are all powder polycarboxylate water-reducers), raw materials in parts by weight, including: 5 parts of pre-hydrated cement particles, 5 parts of dispersed agent, 90 parts deionized water.

[0038] The prehydration cement particles used, and its preparation method, include the following steps: uniformly stirring deionized water and cement to obtain cement slurry, performing curing treatment on the cement slurry, grinding after crushing, and sieving to obtain the prehydration cement particle. For cement particles, the mesh of the sieve is a square sieve, and the mesh size (side length) of the sieve is 75 μm. Wherein, the water-cement ratio of...

Embodiment 2

[0044] Embodiment 2 provides a kind of seed type early strengthening agent, and proportioning ratio is as shown in table 3, and the dispersant described in table 3 is powder polycarboxylate superplasticizer (the dispersant used in embodiment 1-5 is powder Body polycarboxylate superplasticizer), raw materials by weight, including: 9 parts of pre-hydrated cement particles, 11 parts of dispersant, 80 parts of deionized water.

[0045] The prehydration cement particles used, and its preparation method, include the following steps: uniformly stirring deionized water and cement to obtain cement slurry, performing curing treatment on the cement slurry, grinding after crushing, and sieving to obtain the prehydration cement particle. For cement particles, the mesh of the sieve is a square sieve, and the mesh size (side length) of the sieve is 75 μm. Wherein, the water-cement ratio of deionized water and cement is 0.4; the temperature of the curing treatment is 20 degrees Celsius, and t...

Embodiment 3

[0051] Embodiment 3 provides a kind of seed crystal type early strengthening agent, proportioning as shown in table 3, and the dispersant described in table 3 is powder polycarboxylate superplasticizer (the dispersant used in embodiment 1-5 is powder Body polycarboxylate superplasticizer), raw materials by weight, including: 7 parts of pre-hydrated cement particles, 8 parts of dispersant, 85 parts of deionized water.

[0052]The prehydration cement particles used, and its preparation method, include the following steps: uniformly stirring deionized water and cement to obtain cement slurry, performing curing treatment on the cement slurry, grinding after crushing, and sieving to obtain the prehydration cement particle. For cement particles, the mesh of the sieve is a square sieve, and the mesh size (side length) of the sieve is 75 μm. Wherein, the water-cement ratio of deionized water and cement is 0.70; the temperature of the curing treatment is 30 degrees Celsius, and the cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com