Adjustable steel back arris for formwork reinforcing of fabricated L-shaped cast-in-situ embedded column and implementing method of adjustable steel back arris

A formwork reinforcement and adjustable technology, which is applied to formwork/formwork/work frame, joints of formwork/formwork/work frame, preparation of building components on site, etc. Horizontal surface, openings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

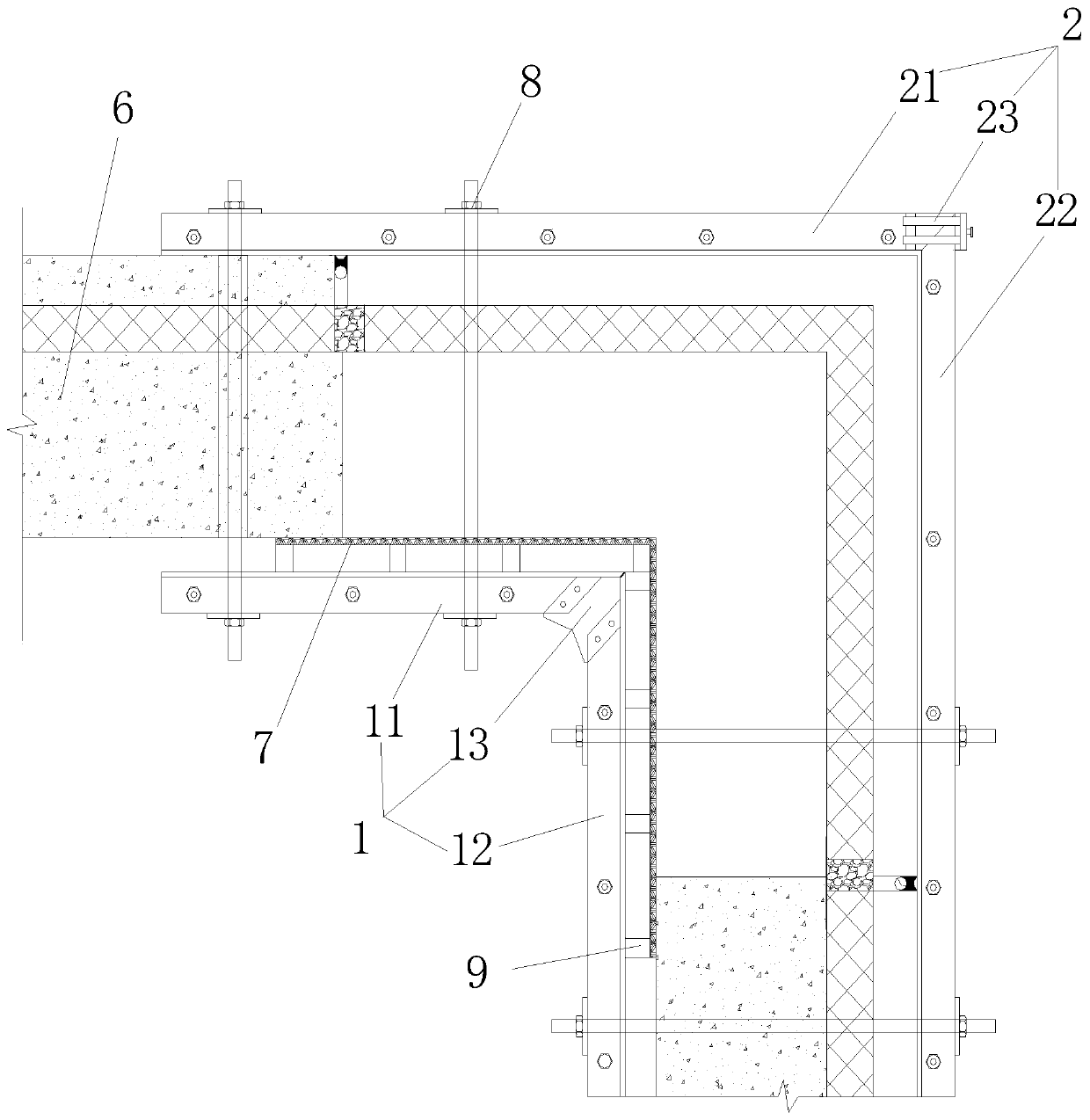

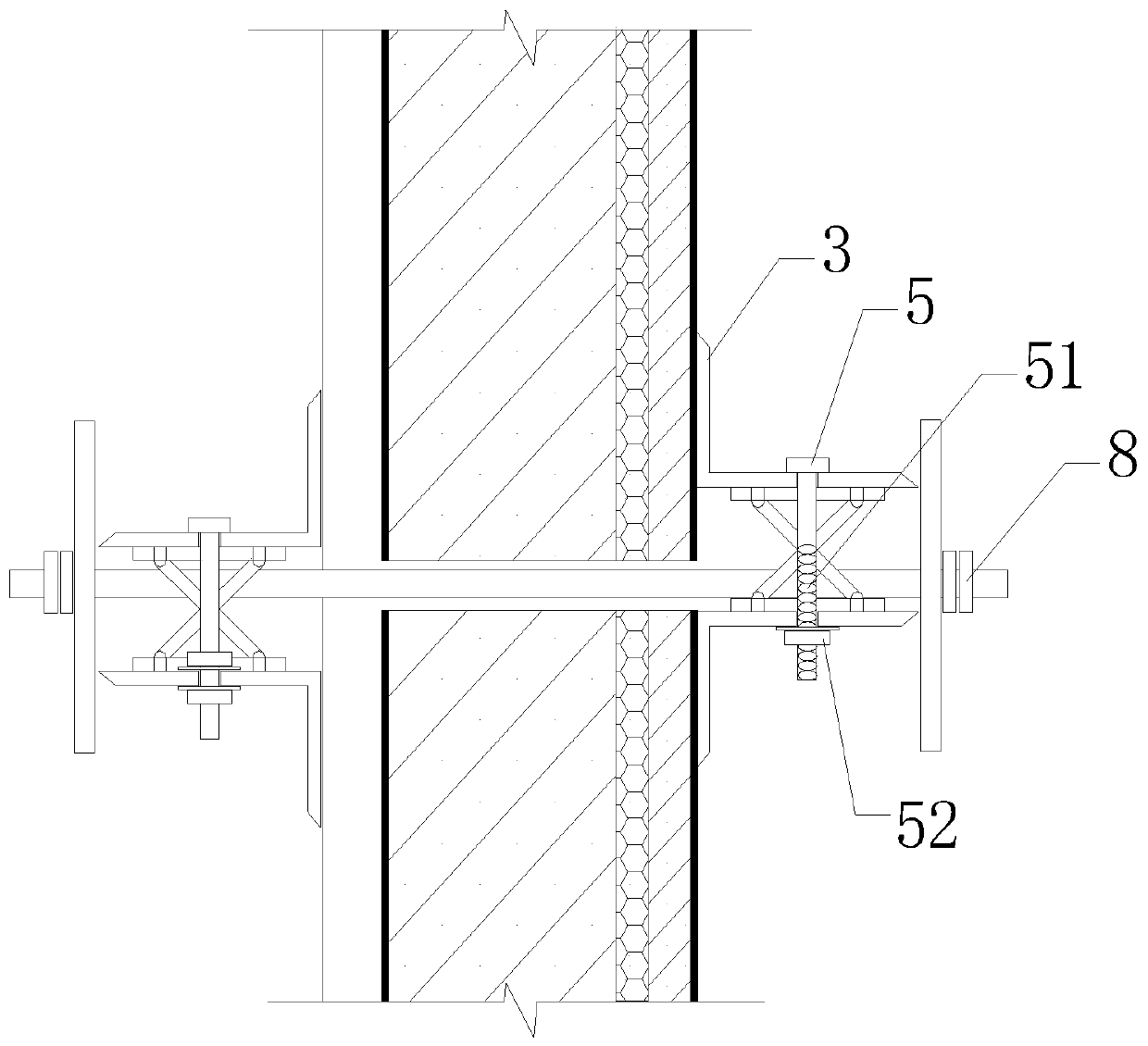

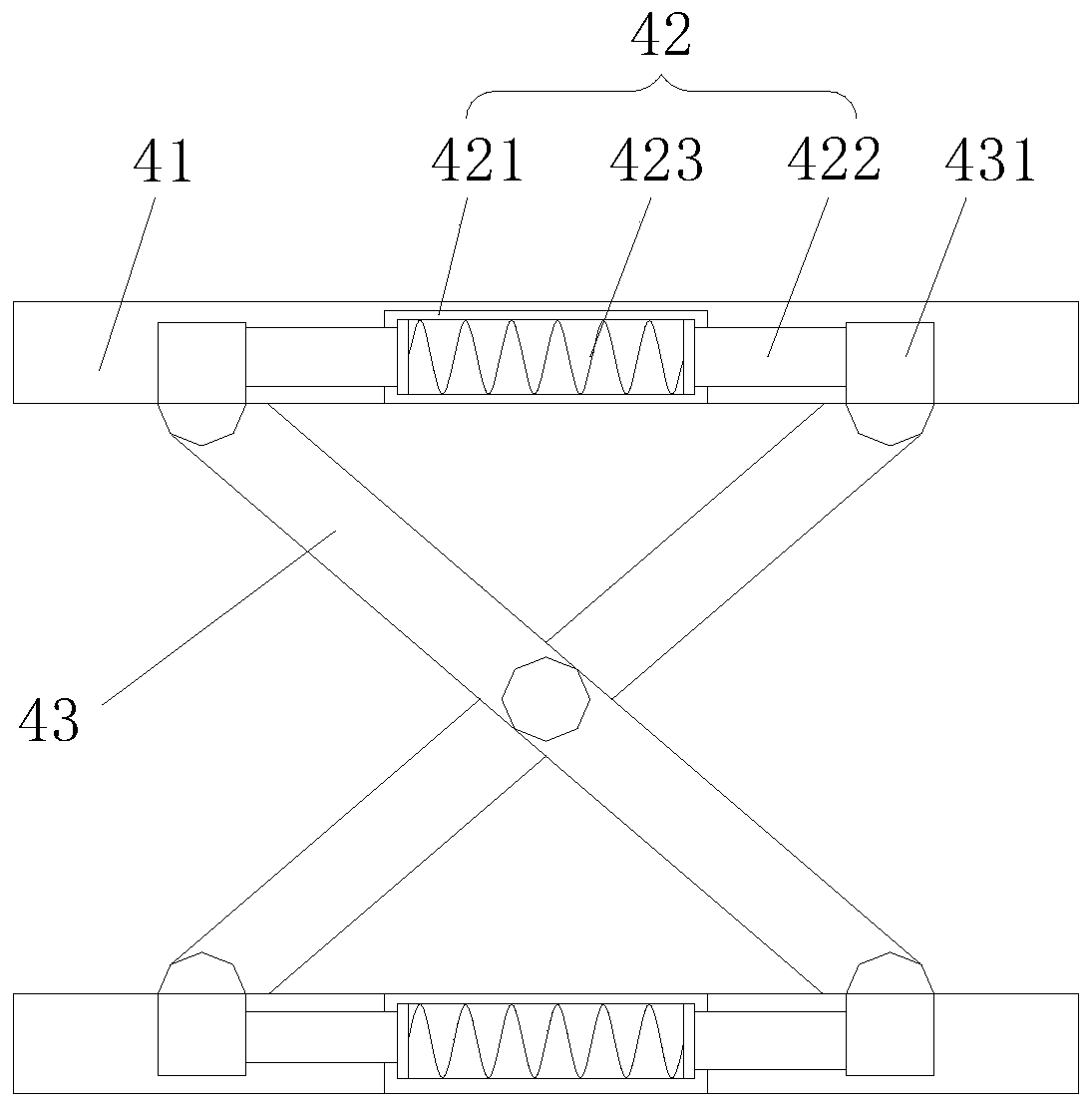

[0035] Such as Figure 1 to Figure 6As shown, the adjustable assembly L-shaped cast-in-place concealed column formwork reinforcement steel back flute includes the inner corner back flute assembly 1 and the outer corner back flute assembly 2, and the inner corner back flute assembly 1 includes the first adjustable back flute Assembly 11, the second adjustment back flute assembly 12 and the first connection assembly 13, the male corner back flute assembly 2 includes the third adjustment back flute assembly 21, the fourth adjustment back flute assembly 22 and the second connection assembly 23, the first adjustment The back flute assembly 11 , the second adjustment back flute assembly 12 , the third adjustment back flute assembly 21 and the fourth adjustment back flute assembly 22 are all adjusted in the vertical direction.

[0036] Among them, the first adjusting back flute assembly 11, the second adjusting back flute assembly 12, the third adjusting back flute assembly 21 and th...

Embodiment 2

[0042] Such as Figure 1 to Figure 6 As shown, the implementation method of the steel back flute for the reinforcement of the adjustable assembly L-shaped cast-in-place concealed column formwork includes the following steps:

[0043] Step 1. Installation of the prefabricated wallboard 6 and formwork 7: hoist the prefabricated wallboard 6 to the designed position, clean the ground around the concealed column, and use the formwork 7 to hang on the outer side wall of the prefabricated wallboard 6 through the pull bolts 8;

[0044] Step 2. Installation of inner corner back flute assembly 1 and outer corner back flute assembly 2:

[0045] A1. Assembling the first adjusting back flute component 11, the second adjusting back flute component 12 and the first connecting component 13:

[0046] The connecting plate 131 uses the positioning groove 13111 of the positioning area 1311 to cooperate with the L-shaped plate 3 of the first adjustment back flute assembly 11 and the second adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com