Hydraulic oscillator for directional drilling operation

A hydraulic oscillator and directional drilling technology, applied in directional drilling, drilling with vibration, etc., can solve the problems of fast oscillation frequency, small oscillation amplitude, instability, etc., and achieve slow oscillation frequency, stable oscillation amplitude and period, and long service life. prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. The above application content makes some non-essential improvements and adjustments to this application.

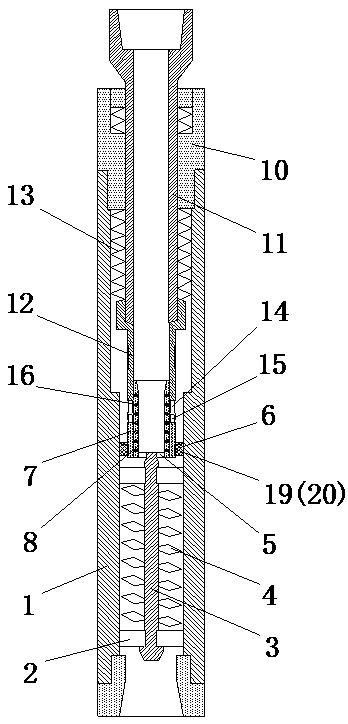

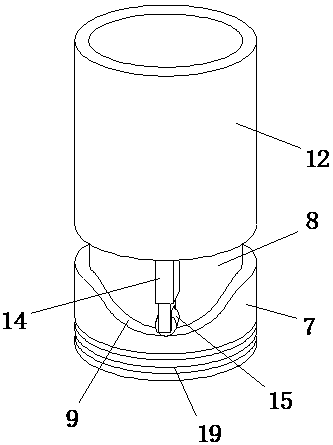

[0023] combine Figure 1 to Figure 4 As shown, a hydraulic vibrator for directional drilling operations consists of a power sub-section and a vibrating sub-section.

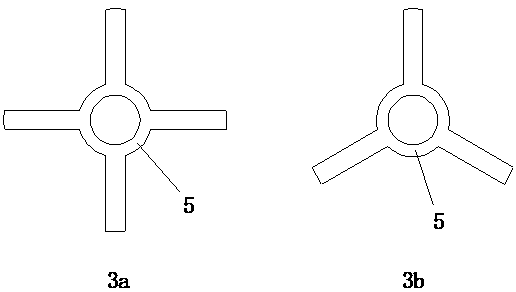

[0024] Among them, the power short joint includes a power casing 1, a bearing 2, a rotating shaft 3, a blade 4, a connecting frame 5, a rotating cylinder and a piston 6, and the rotating shaft 3 is movably connected in the power casing 1 through a bearing 2, and some water-permeable holes are provided on the bearing 2 (not shown in the figure), used for the circulation of drilling fluid; the blades 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com