Impeller for centrifugal ventilating machine

A centrifugal fan and impeller technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as noise generation and affect fan efficiency, and achieve the effect of increasing pressure, reducing flow loss and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

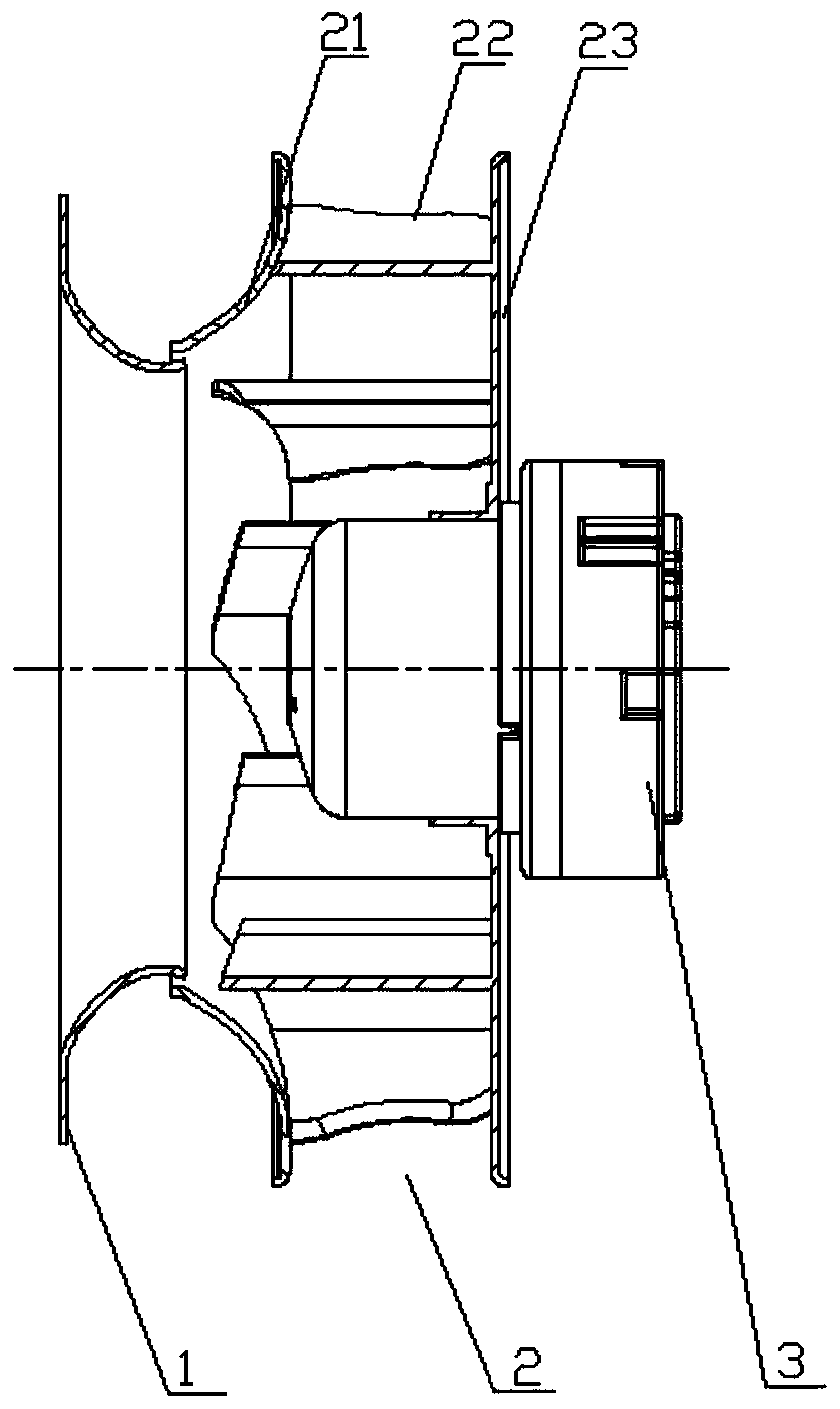

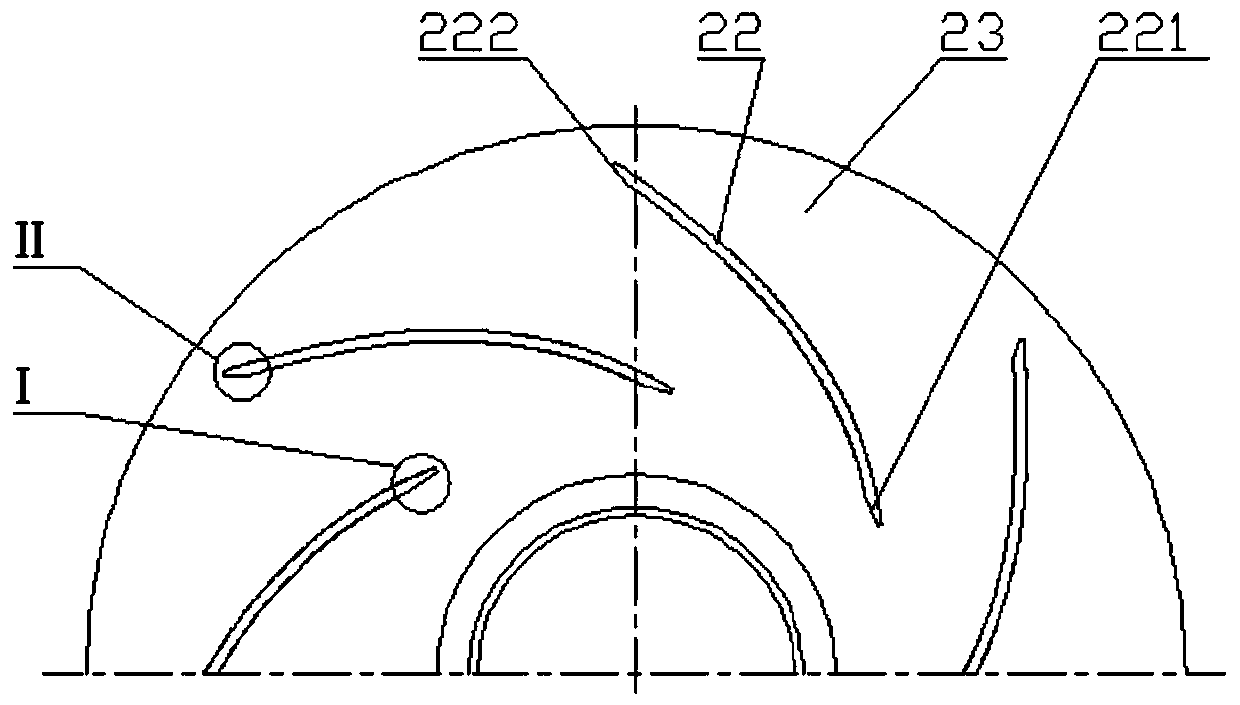

[0028] refer to figure 1 , this figure is a schematic diagram of an embodiment of a centrifugal fan of the present invention, the fan includes: an air inlet 1, an impeller 2, a motor 3, the air inlet 1 is matched with the impeller 2, and the rotation of the motor 3 drives the impeller 2 Rotate so that the airflow is sucked into the impeller from the air inlet. Wherein the impeller 2 comprises a front disc 21, blades 22 and a rear disc 23, between the front disc 21 and the rear disc 23 are provided with a plurality of arc-shaped blades, each blade has 4 edges, and the two edges of the side are respectively connected with the front disc. 21 is connected with the rear disc 23, and the airflow enters the inside of the impeller from the inner hole of the front disc 21, and flows out from the outer periphery of the impeller after passing through the passage between each blade.

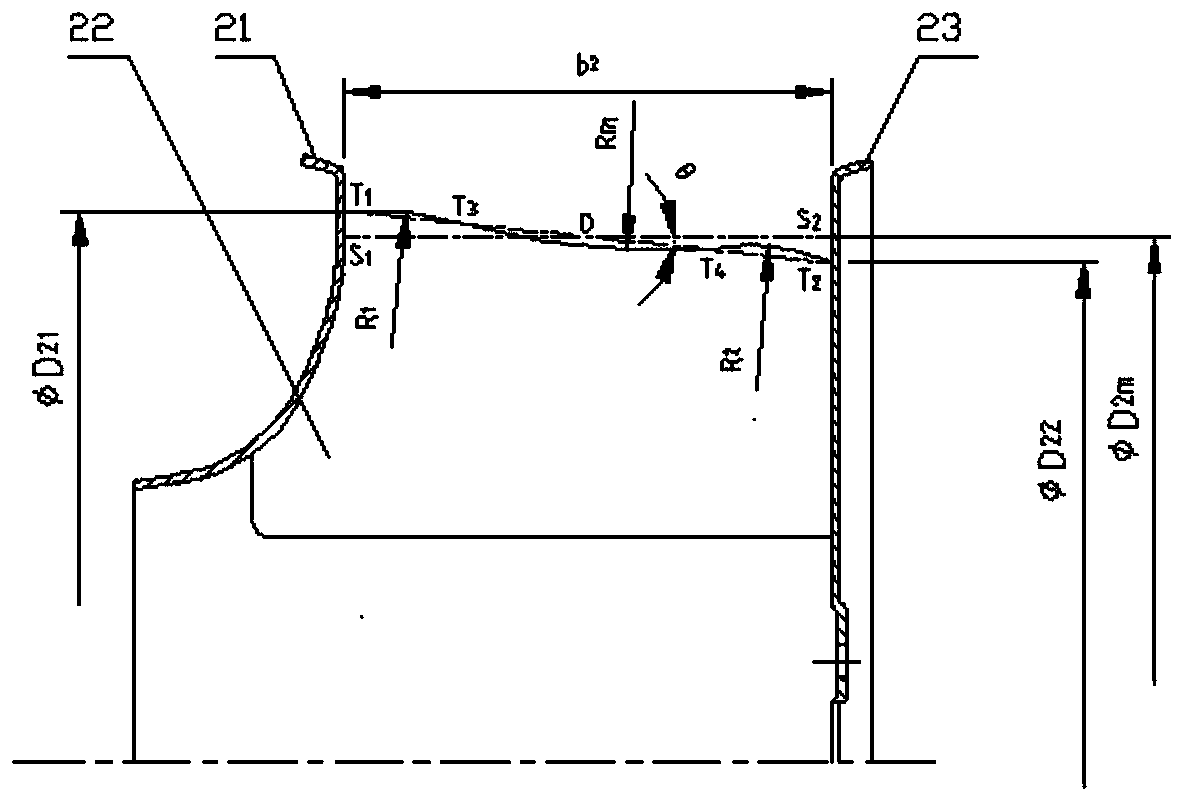

[0029] refer to figure 2 , the outer edge of the blade is a compound arc "T 1 T 3 T 4 T 2 ”, the s...

Embodiment 2

[0044] The main structural parameters of embodiment 2 of the present invention and its conventional comparison prototype 2 are as follows:

[0045] Impeller diameter (blade outer diameter): ΦD 2 = ΦD 2m =Φ570mm,

[0046] Impeller outlet width: b 2 =160mm,

[0047] Blade thickness: 2.5mm.

[0048] Compared with the conventional comparative prototype 2, the outer edge of the blade of the embodiment 2 prototype is a compound curve, and the outer edge of the blade of the comparative prototype 2 is a straight line segment parallel to the central axis, and the blade in the impeller of the embodiment 2 prototype The average value of the outer diameter is equal to the value of the outer diameter of the blade of the comparative prototype 2. The inner diameter and outer diameter of the blade of the prototype of Example 2 have been chamfered, and the blades of the comparative prototype 2 have not been chamfered. The motors and operating speeds are the same.

[0049] The data compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com