Array LED microstructure for obtaining uniform light spots

A technology of LED structure and microstructure, which is applied to semiconductor devices of light-emitting elements, light sources, electric light sources, etc., can solve the problems of uneven distribution of light intensity, uneven distribution of light intensity of a single LED, affecting the optical error of image capture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

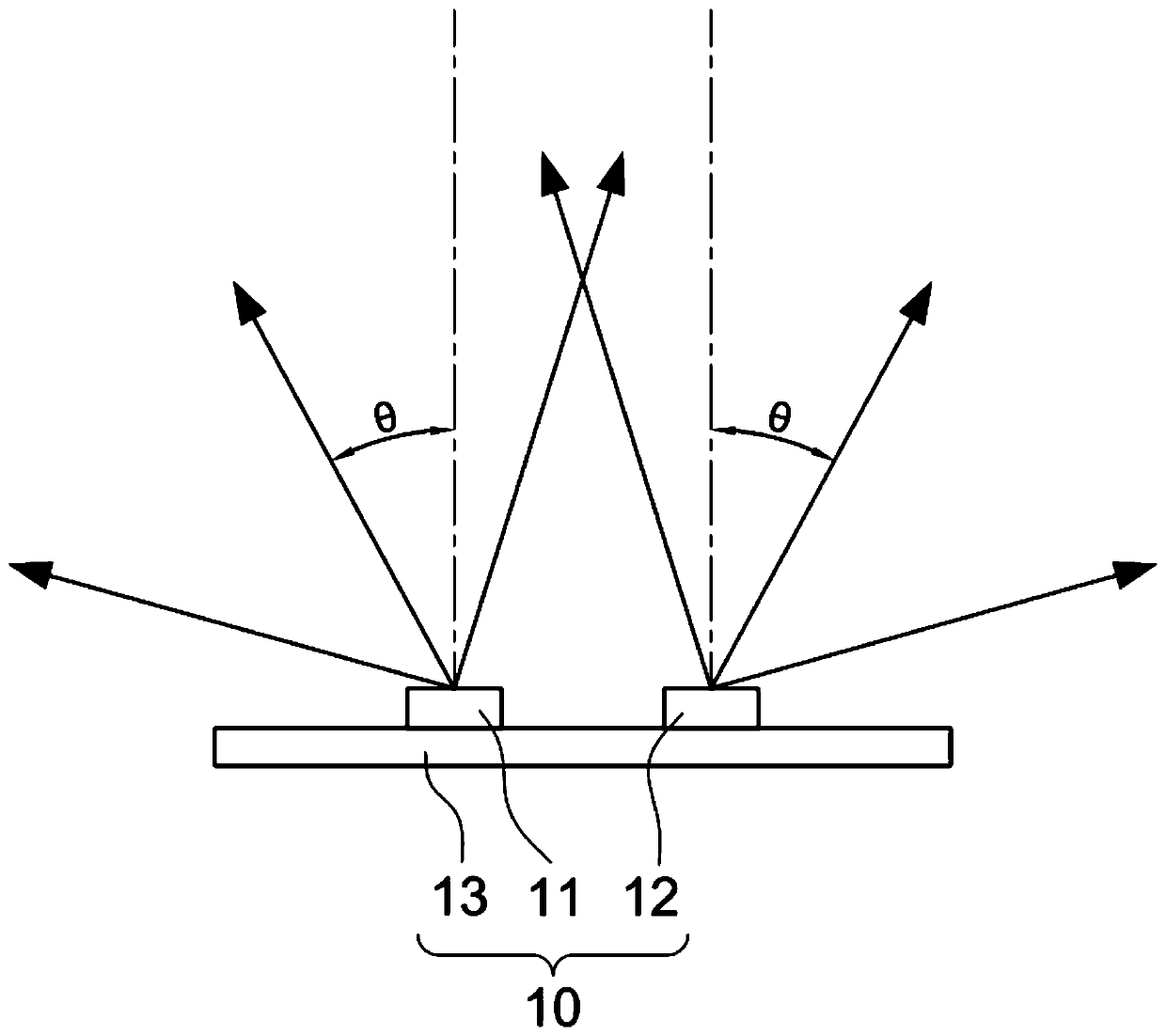

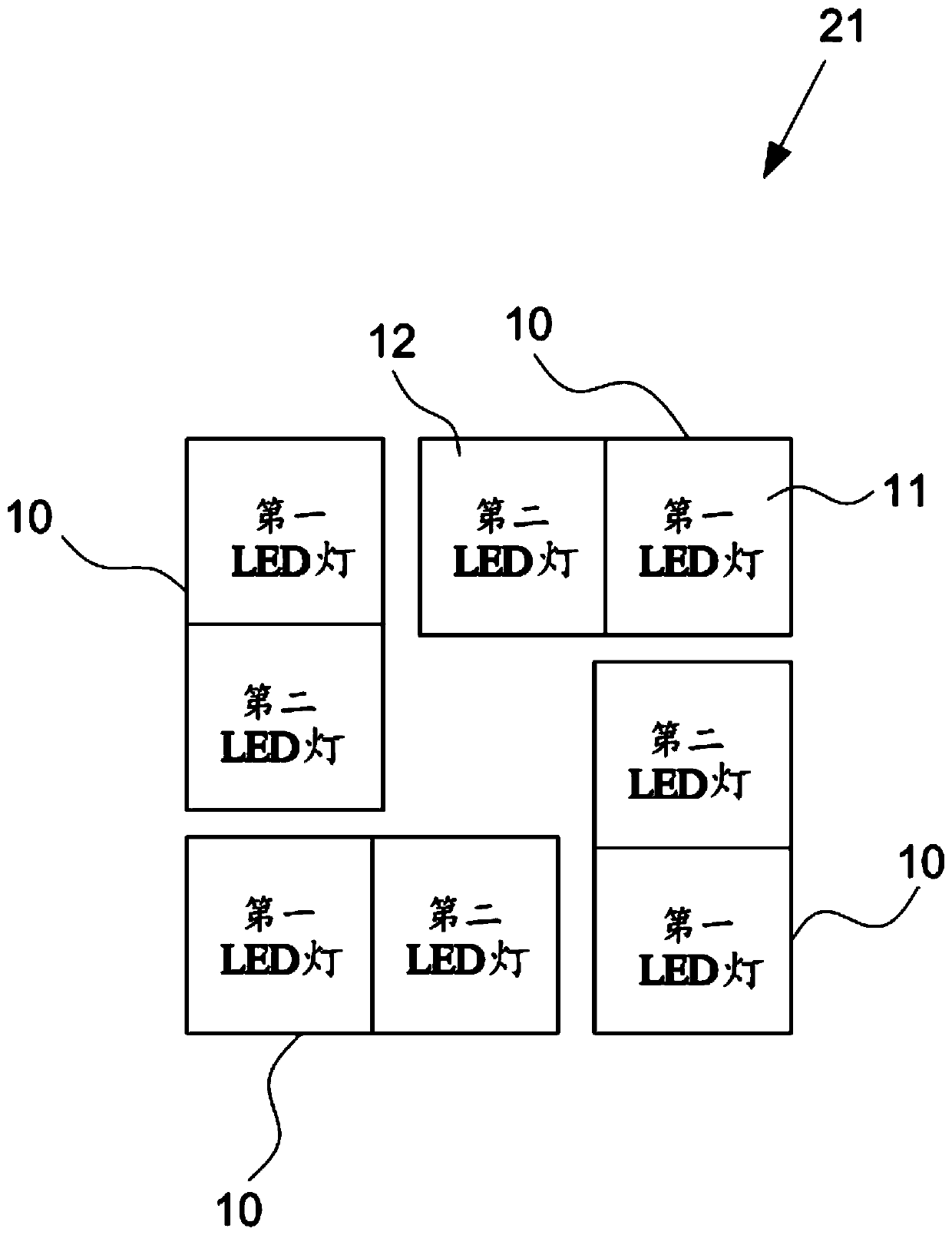

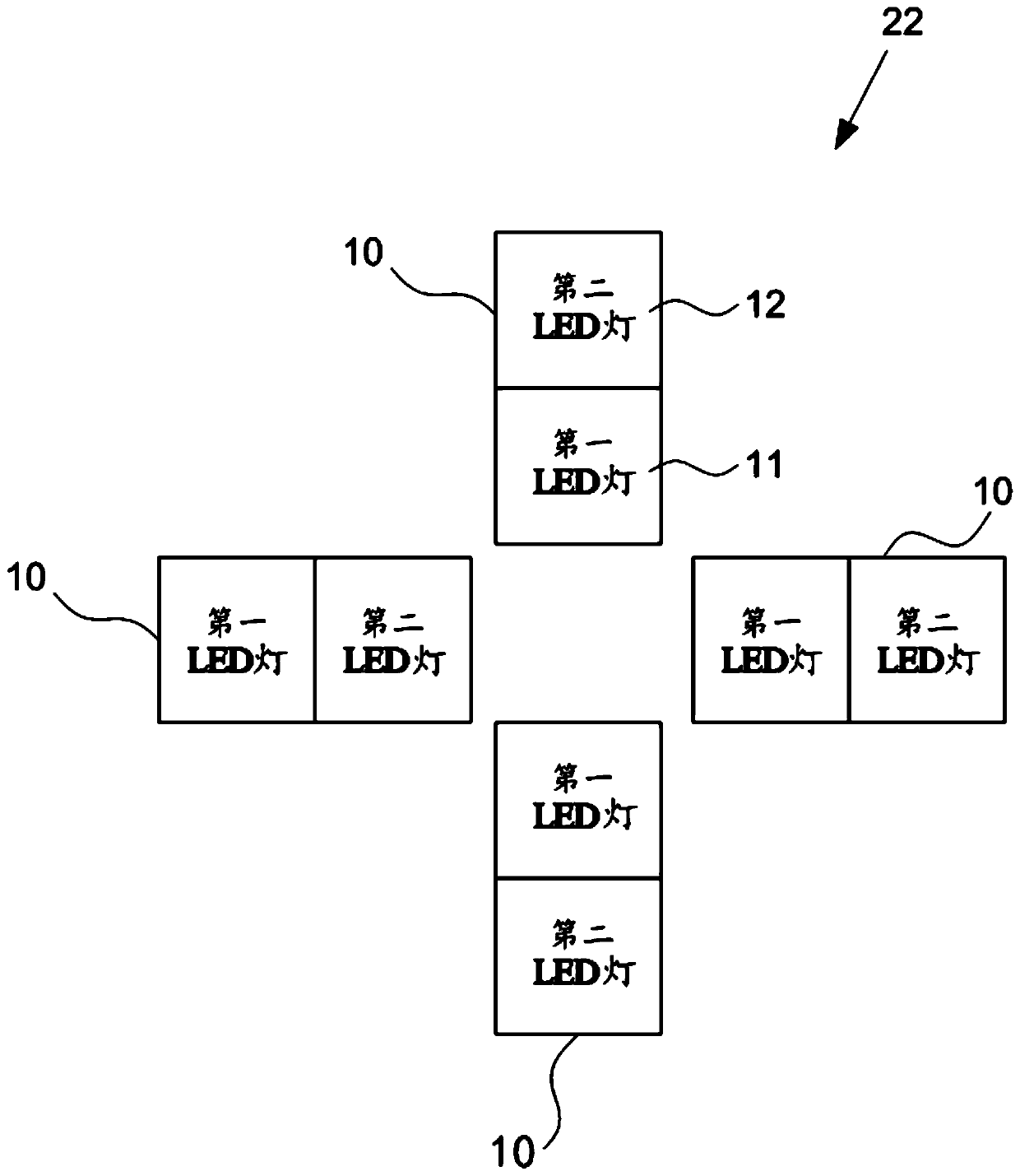

[0025] The present invention is about an "array LED microstructure for obtaining uniform light spots", please refer to figure 1 As shown, the array LED microstructure for obtaining a uniform light spot in the present invention mainly includes: an LED unit 10 .

[0026] Wherein, the LED unit 10 has a first LED lamp 11 and a second LED lamp 12, the first LED lamp 11 is set on a circuit 13 at an inclination angle Θ to the center line of -16 degrees to -22.2 degrees, and The second LED lamp 12 is also arranged on the circuit 13, at a distance of 10mm (millimeters) from the first LED lamp 11, and is arranged on the circuit 13 at an inclination angle Θ to the center line of +16° to +22.2° .

[0027] With the composition of the above components, the first and second LED lamps 11, 12 are designed to have an inclination angle Θ relative to the center line, successfully solving the problem of insufficient brightness of a single LED, and the first and second LED lamps 11, 12 In the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com