Explosion-proof door for waste heat boiler and waste heat boiler

A waste heat boiler and explosion-proof door technology, which is applied to the components of steam boilers, steam boilers, steam boiler accessories, etc., can solve problems such as long-term shutdown, and achieve the effect of quickly restoring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

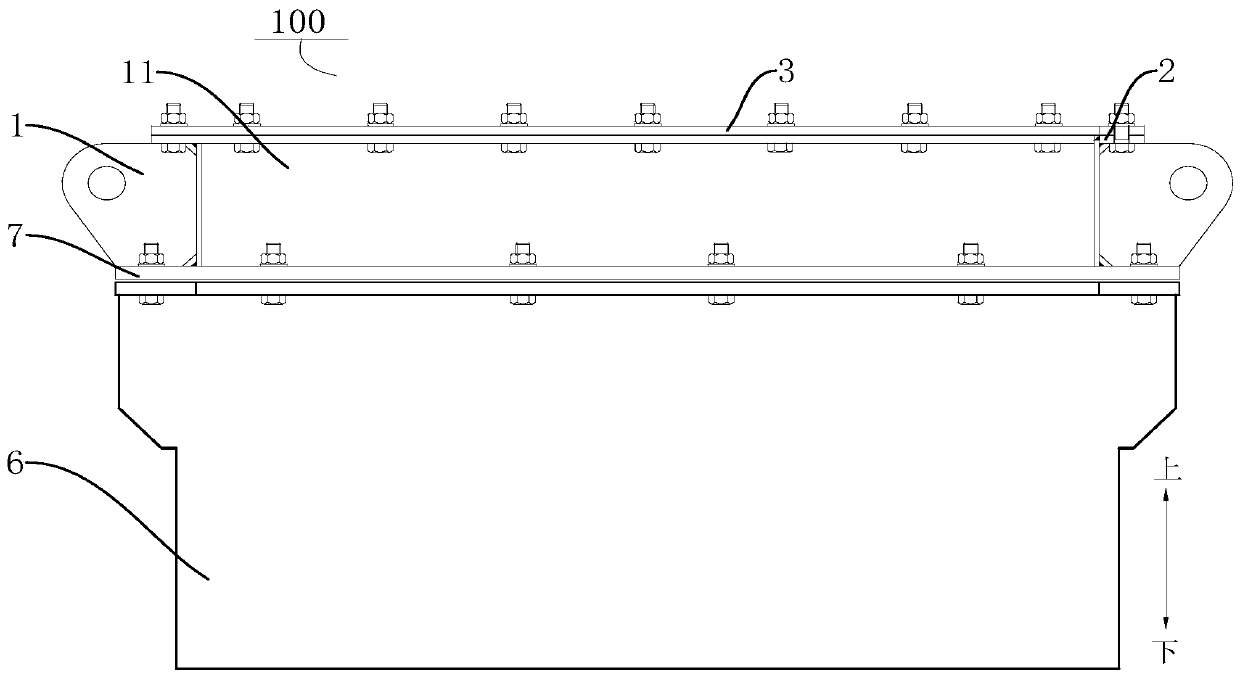

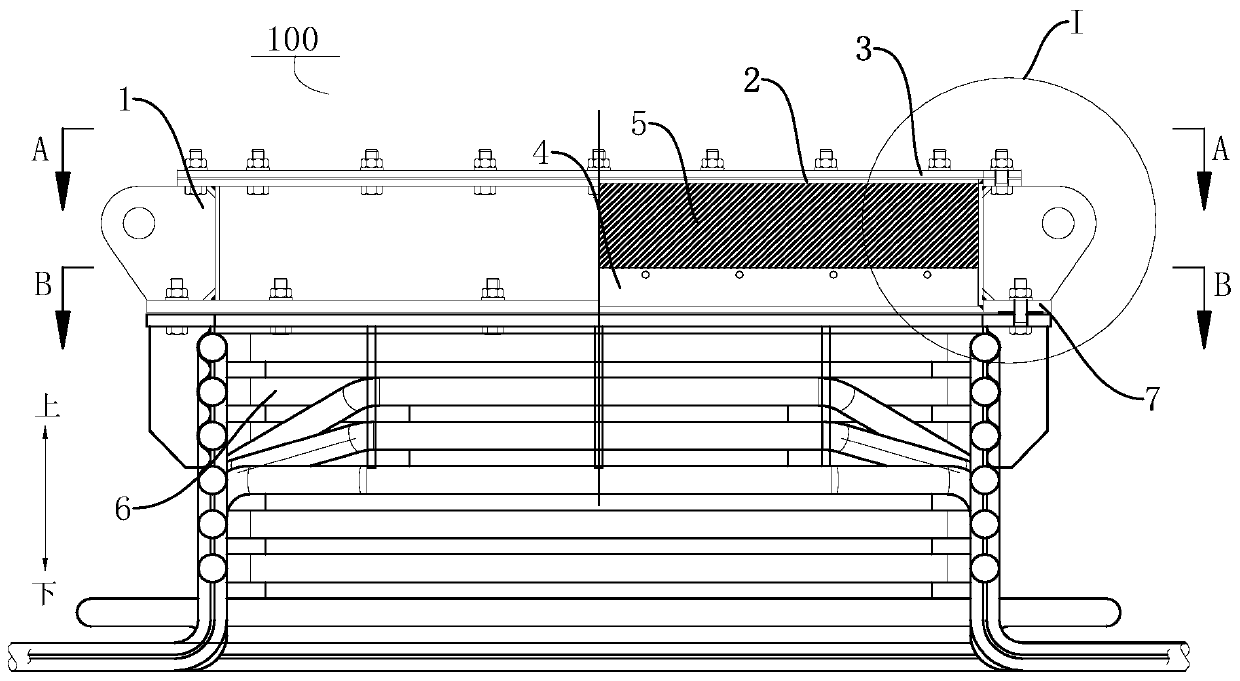

[0073] An explosion-proof door 100 for a waste heat boiler, comprising: an explosion-proof door connecting pipe 1, a first flange 2, an explosion-proof diaphragm 3, a grid 4, a buffer temperature-resistant layer 5, a cooling member 6, a second flange 7 and a protective cover.

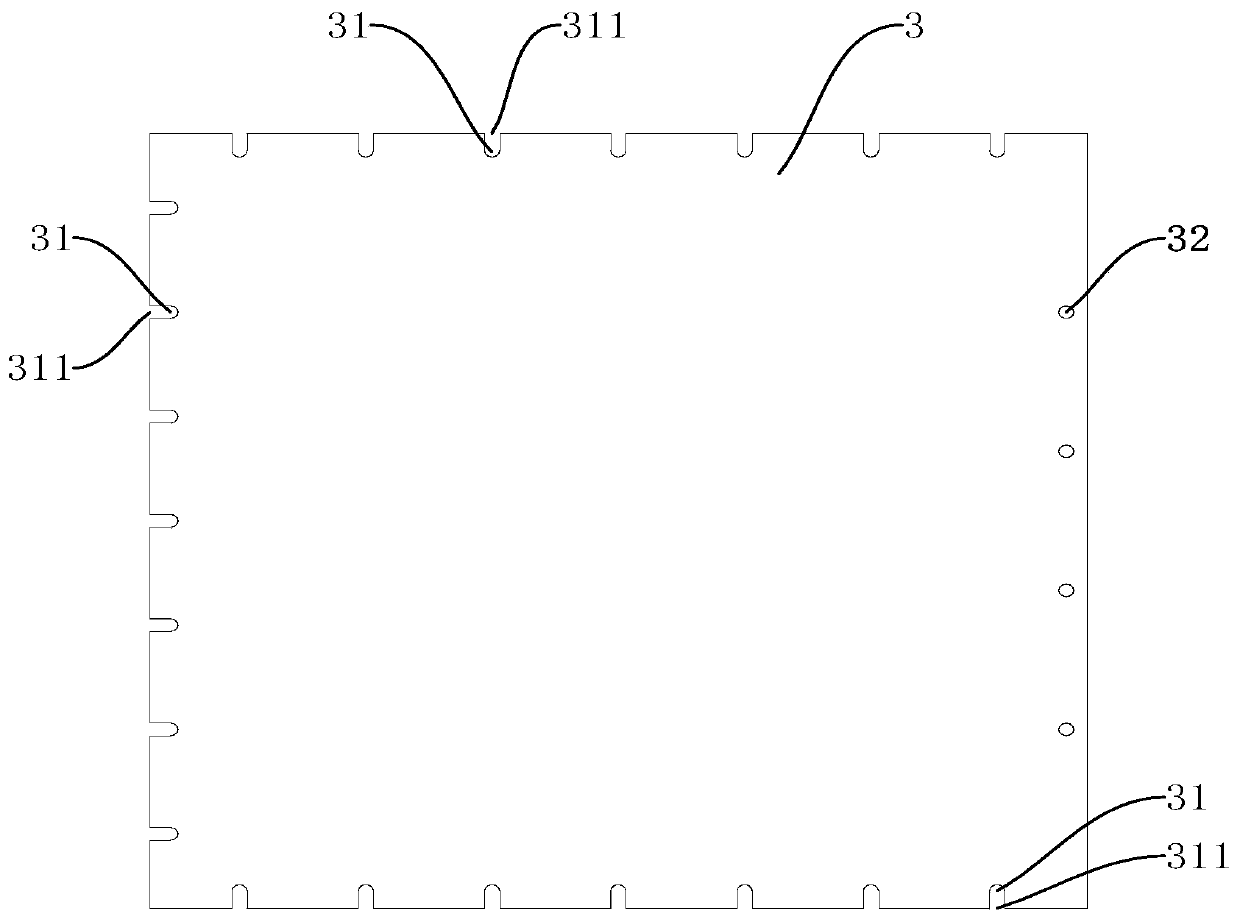

[0074] Such as figure 1 As shown, the explosion-proof door connecting pipe 1 is generally formed into a vertical square cylindrical structure, and one end of the explosion-proof door connecting pipe 1 forms an outlet 11 and the other end forms an inlet (both the outlet and the inlet are formed in a square shape). Such as figure 2 and Figure 4 As shown, the outlet 11 of the explosion-proof door connecting pipe 1 is connected with a first flange 2 . Such as Figure 5 As shown, an explosion-proof diaphragm 3 is pressed between the first flange 2 and the explosion-proof door adapter 1, and a bolt connection is provided between the explosion-proof diaphragm 3 and the first flange 2 and the explosion-pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com