Double-system microchannel collecting pipe

A micro-channel and dual-system technology, applied to tubular components, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of high difficulty and high cost, and achieve the effect of reducing the charging amount, small volume, and improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

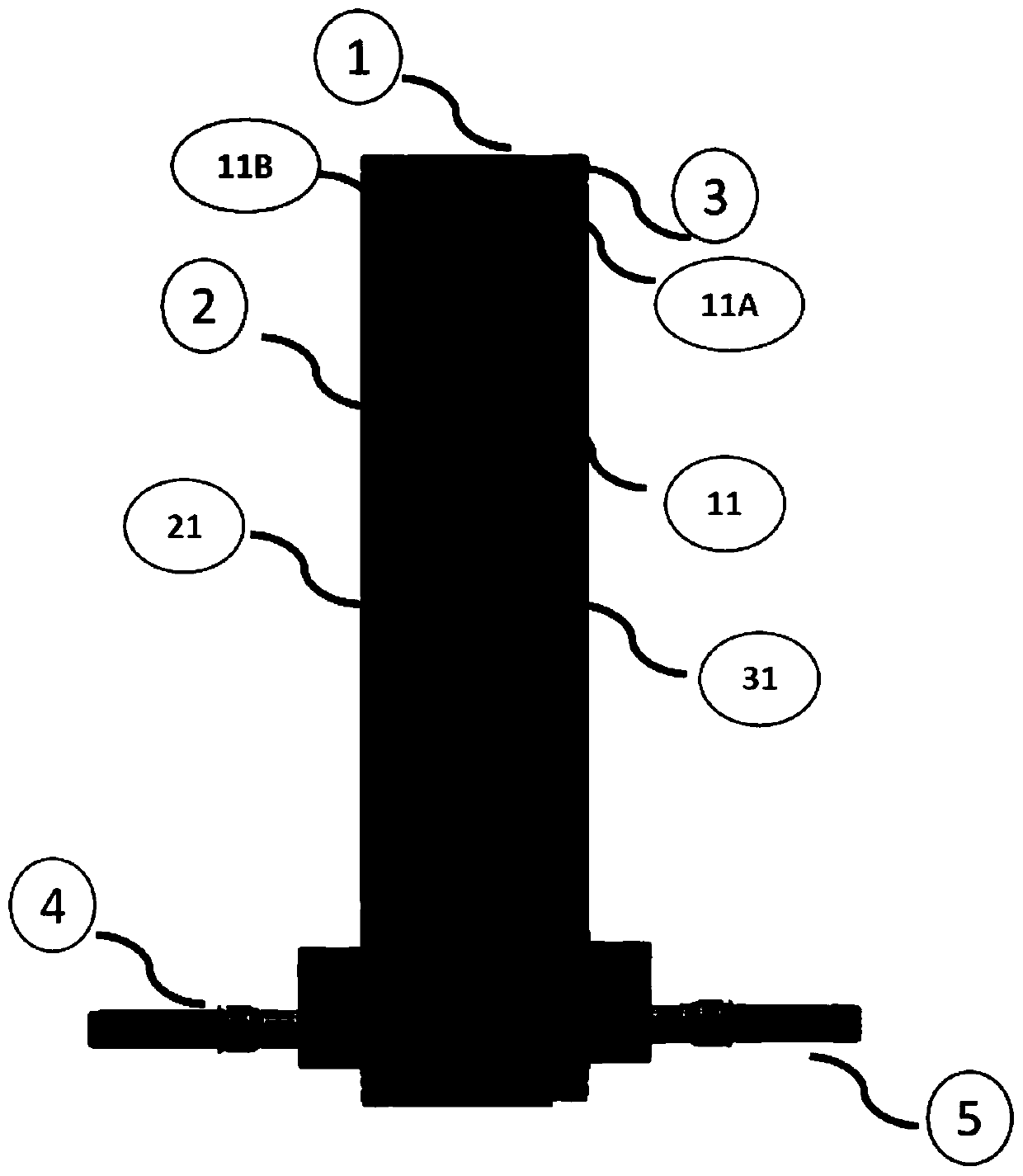

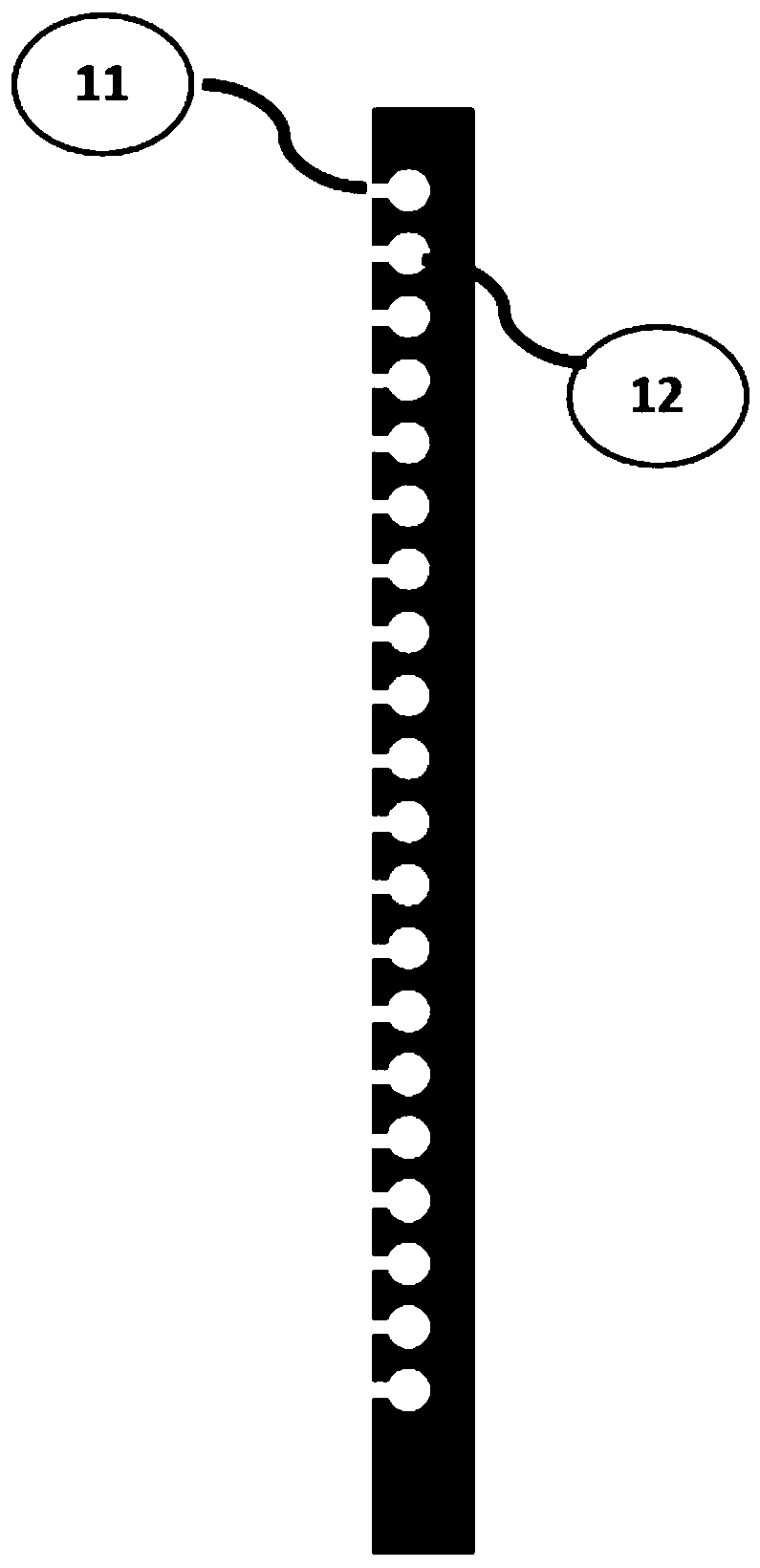

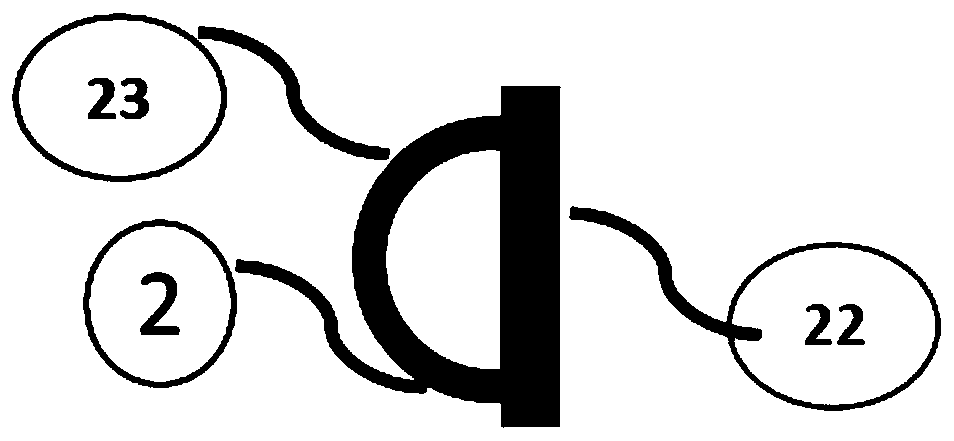

[0035] The refrigerant of the first system flows in from the first connection pipe 4 and enters the first communication part 2. The refrigerant of the first system flows in the communication channel of the first communication part 2, enters the channel 12 through the through hole 22A, and enters the corresponding first system flat. The pipe interface 11A enters the heat exchange flat tube of the first system for heat exchange; the refrigerant of the second system flows in from the second connecting pipe 5 and enters the second communication part 3, and the refrigerant of the second system flows through the communication channel of the second communication part 3 The flow enters the channel 12 through the through hole 33A, enters the corresponding second system flat tube interface 11B, and enters the second system heat exchange flat tube for heat exchange.

Embodiment approach 2

[0037] The refrigerant of the first system flows out from the flat tube, passes through the flat tube interface 11A of the first system, enters the channel 12, passes through the through hole 22A, enters the first communication part 2 together, and flows out from the first connecting pipe 4; the refrigerant of the second system flows from the The flat tube flows out, passes through the flat tube interface 11B of the second system, enters the channel 12 , passes through the through hole 33A, enters the second communication part 3 together, and flows out from the second connecting pipe 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com