Automatic visual technology-based detection system and method of feeder terminal base plate

A technology for detection of feeder terminals and substrates, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of high missed detection rate, long programming and debugging time, etc., achieve high production efficiency, save inspection time, The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

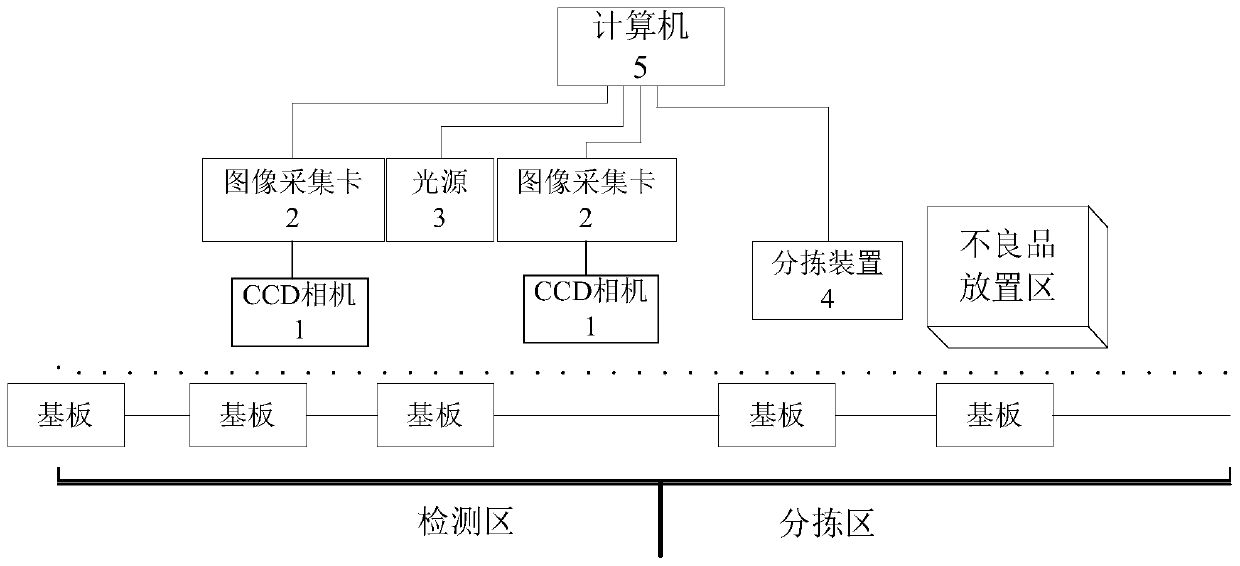

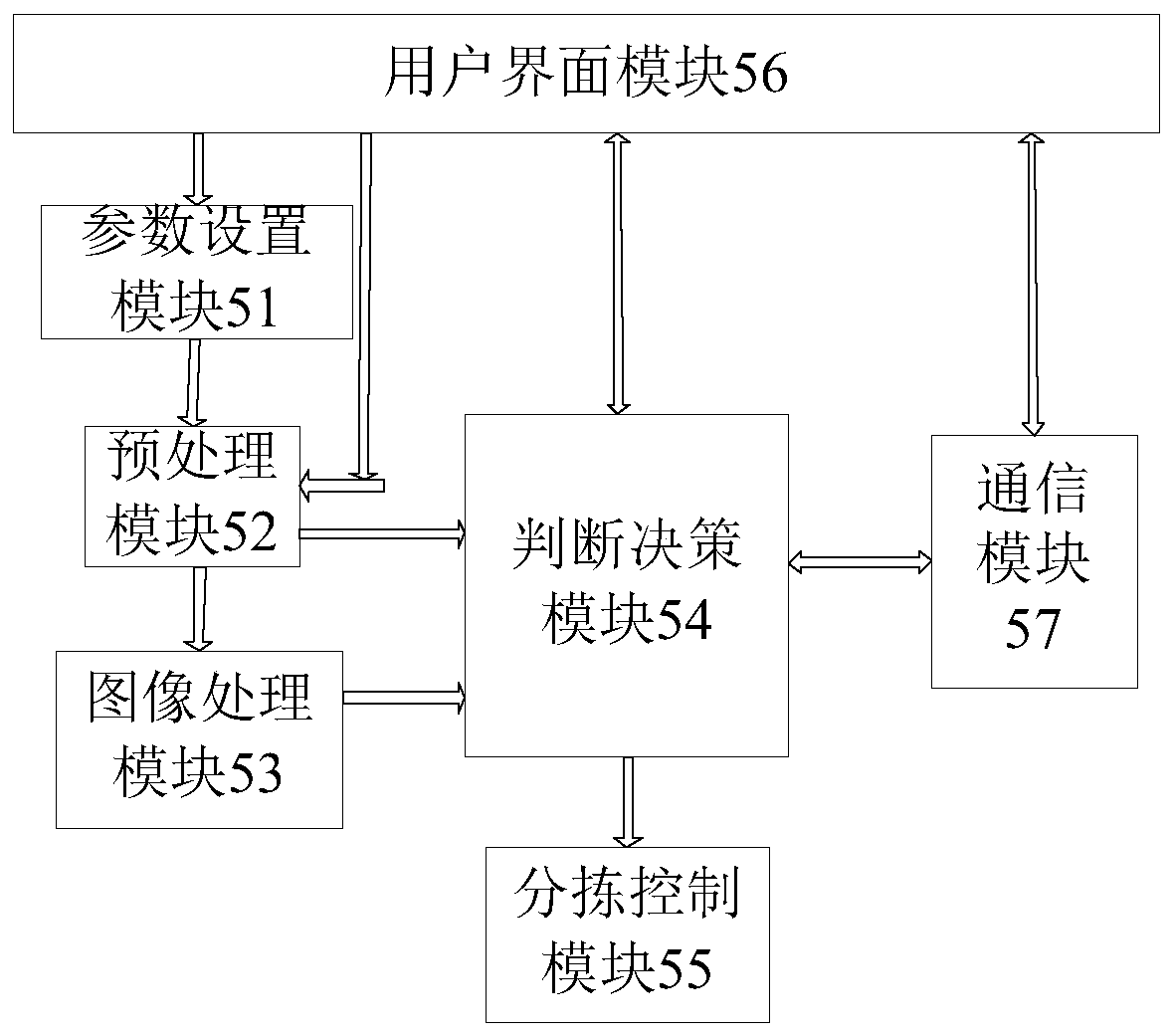

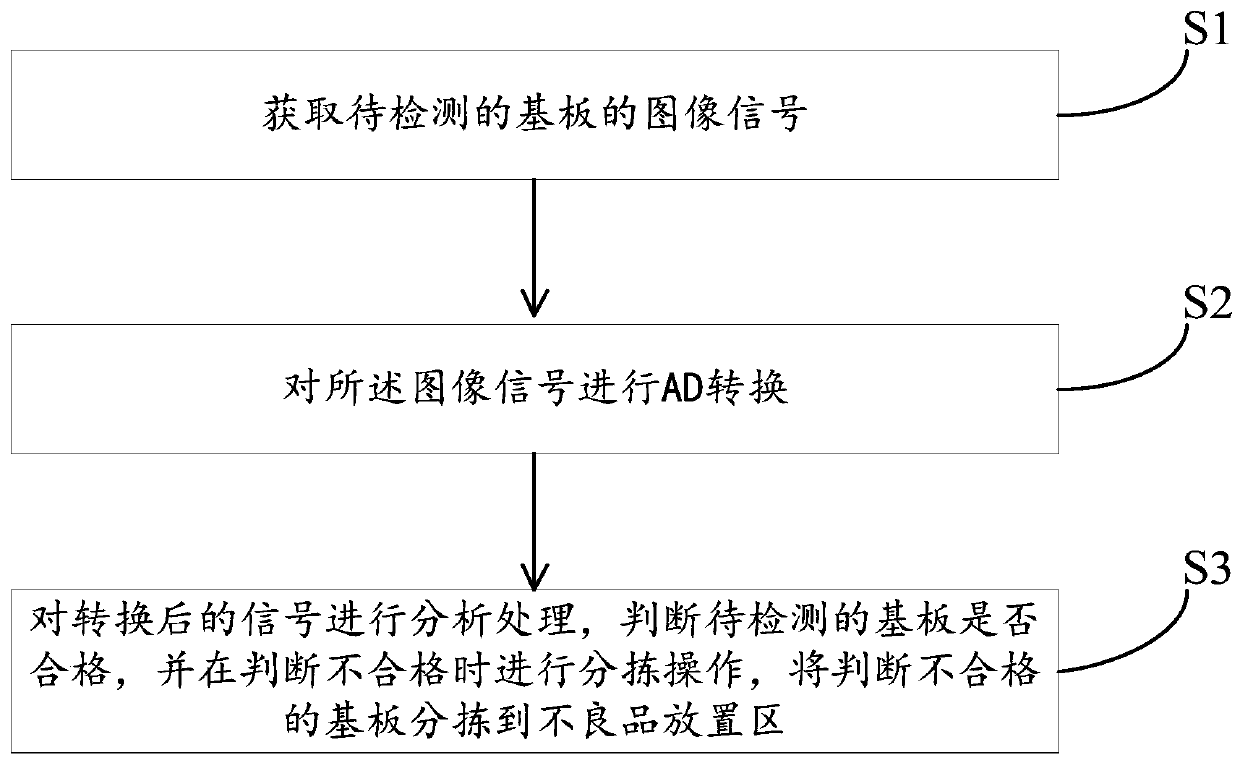

[0043] Embodiments of the present invention provide a feeder terminal substrate inspection system based on automatic vision technology, such as figure 1 As shown, the device includes a CCD camera 1, an image acquisition card 2, a light source 3, a sorting device 4 and a computer 5;

[0044] The CCD camera 1 is installed above the substrate conveyor belt for acquiring image signals of the substrate to be detected;

[0045] The image acquisition card 2 is used for carrying out AD conversion to the image signal output by the CCD camera 1;

[0046] The light source 3 is used to illuminate the shooting area of the CCD camera 1;

[0047] The computer 5 is used to analyze and process the signal output by the image acquisition card 2, judge whether the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com