A closed-loop simulation method of laser three-dimensional forming

A laser three-dimensional forming and closed-loop simulation technology, applied in the field of additive manufacturing, can solve the problems of hindering process control, large result error, lack of monitoring and control of molten pool temperature, etc., to achieve the effect of reducing stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

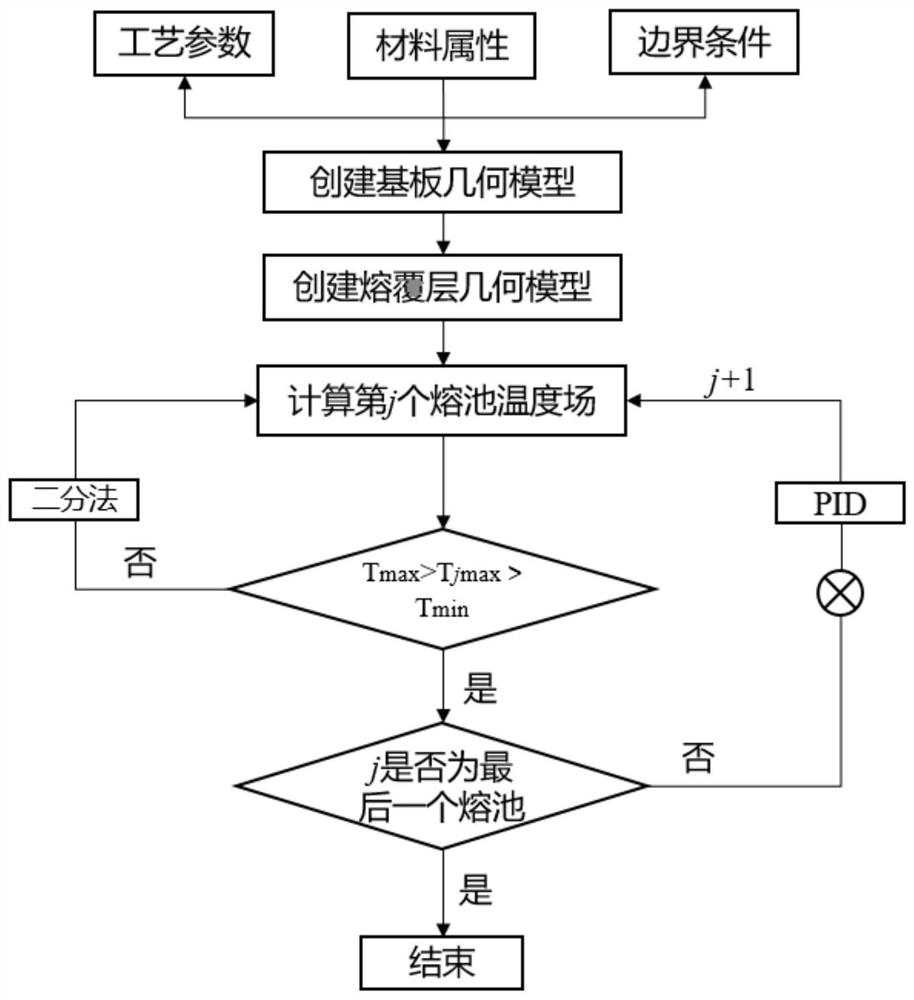

Method used

Image

Examples

Embodiment

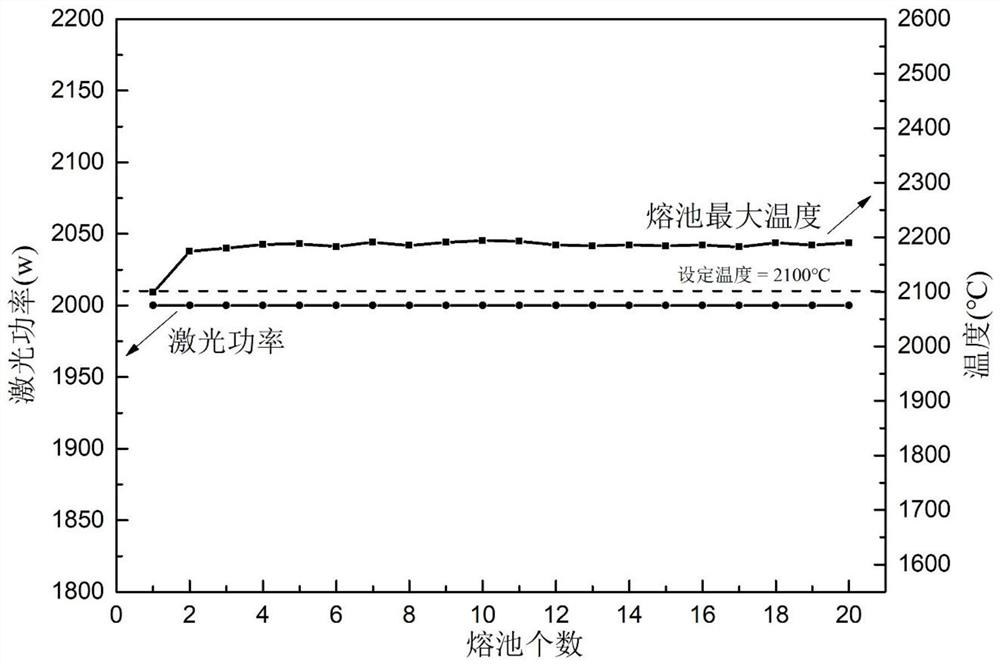

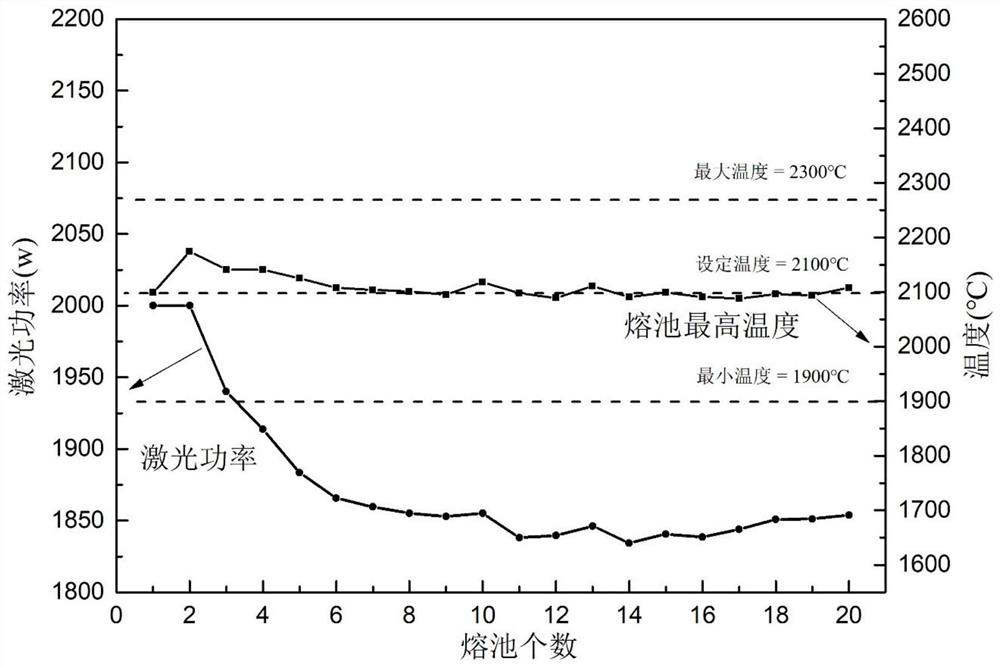

[0059] In the following, only the single-channel single-layer clamped on one side of the laser three-dimensional forming substrate is used as a representative, and it is explained that in the laser three-dimensional forming process, this embodiment is based on the temperature closed-loop control algorithm to optimize the establishment of the thermal-force field finite element model of the laser three-dimensional forming. In the laser three-dimensional process of this example, the material is Ti-6Al-4V titanium alloy, the initial laser power is 2000W, the scanning speed is 10mm / s, the spot diameter is 2mm, the layer thickness is 0.2mm, and the molten pool grid is divided into 2×2 , the forming structure is a single-channel single-layer thin-walled wall clamped by one side of the substrate.

[0060] Step 1. Use the finite element analysis software ABAQUS to establish the geometric model of the substrate and divide the mesh, assign the material properties of the substrate to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com