End free lining plate concrete temperature crack control anti-cracking K value design method

A technology of concrete temperature and design method, applied in the direction of calculation, special data processing applications, instruments, etc., can solve problems such as inapplicability, achieve small calculation errors, simple calculation formulas, and achieve the effect of temperature control and crack prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

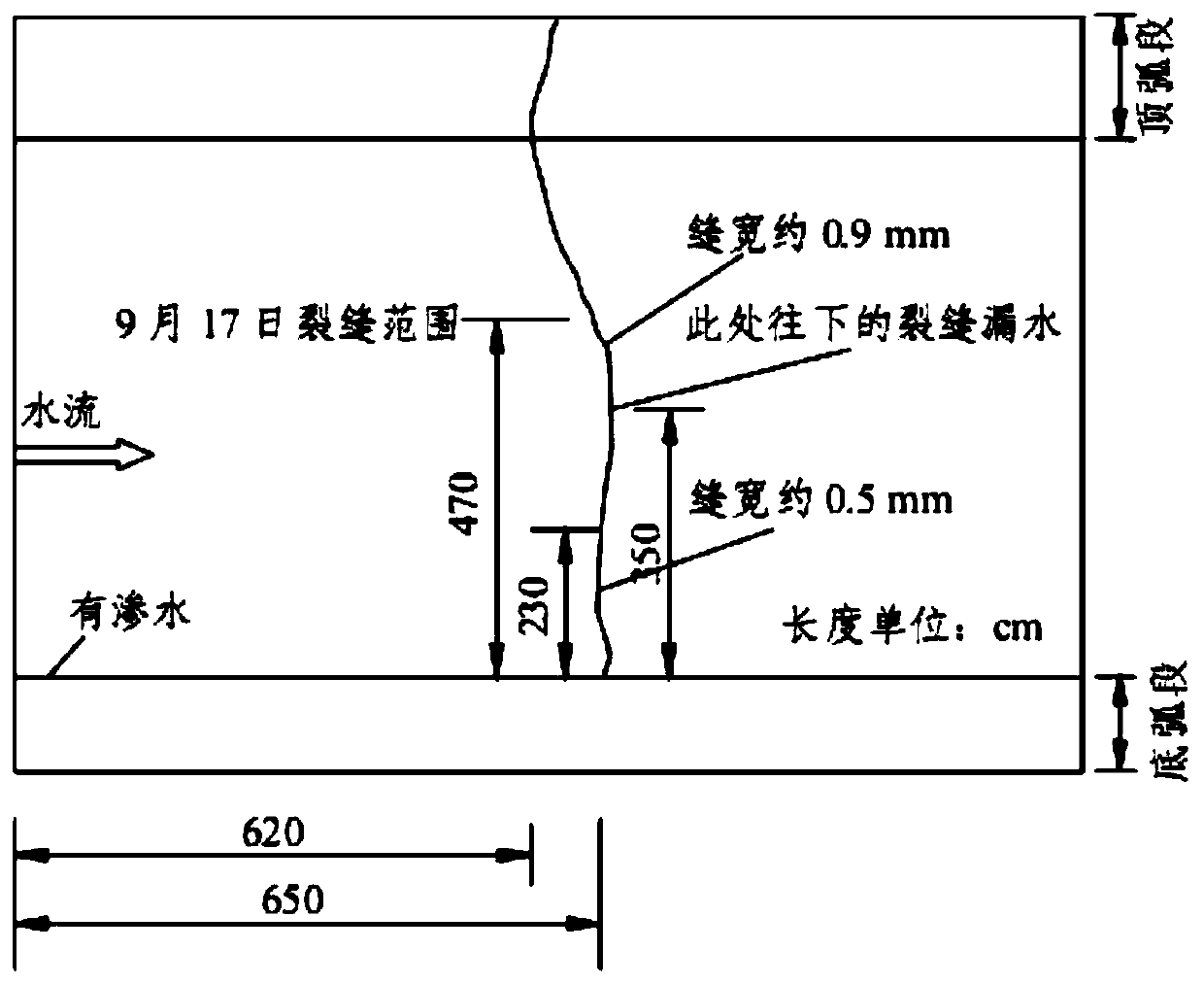

[0090] The right bank of the flood discharge tunnel 3 # 、4 # F2-type 1.0m-thick lining in the Ⅲ1 type surrounding rock area of the door-cavity section in the unpressured section

[0091] Type Ⅲ1 type F2 1.0m thick lining in the surrounding rock area is the right bank of the flood discharge tunnel 3 # 、4 # The structural section with the largest number of door openings in the non-pressure section and the difficulty of temperature control and crack prevention. Right Bank 3 # 、4 # The lining of the door opening section in the non-pressure section is poured in three phases, and the side wall is first poured with a height of 14.87m, which is a free end slab.

[0092] Such as Figure 5 As shown, the method for designing the temperature crack control crack resistance K value of the end free lining slab concrete provided in this embodiment includes the following steps:

[0093] Step 1. Collect data for the calculation of temperature-controlled crack resistance of end-free li...

Embodiment 2

[0112] The right bank 3 of the unpressurized section of the flood discharge tunnel # 、4 # F4-type lining in the Ⅳ category surrounding rock area of the gate-shaped section

[0113] Such as Figure 5 As shown, the method for designing the temperature crack control crack resistance K value of the end free lining slab concrete provided in this embodiment includes the following steps:

[0114] Step 1. Collect data for the calculation of temperature-controlled crack resistance of end-free lining slab concrete

[0115] The basic information is the same as above. Right Bank 3 # 、4 # The lining of the door opening section in the non-pressure section is poured in three phases, and the side wall is first poured with a height of 14.87m, which is a free end slab.

[0116] Step 2. Analyze and determine the temperature control anti-cracking target and the allowable value of the anti-cracking safety factor [K] of the end free slab lining concrete

[0117] The Xiluodu flood discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com