Water cooling temperature control method for optimal water temperature difference of lining concrete with different thicknesses

A technology of water cooling and water temperature difference, applied in design optimization/simulation, special data processing application, geometric CAD, etc., can solve the problem of lack of scientific regulation of lining concrete cooling time, water temperature and temperature drop rate, etc., to achieve temperature control Anti-cracking, scientific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

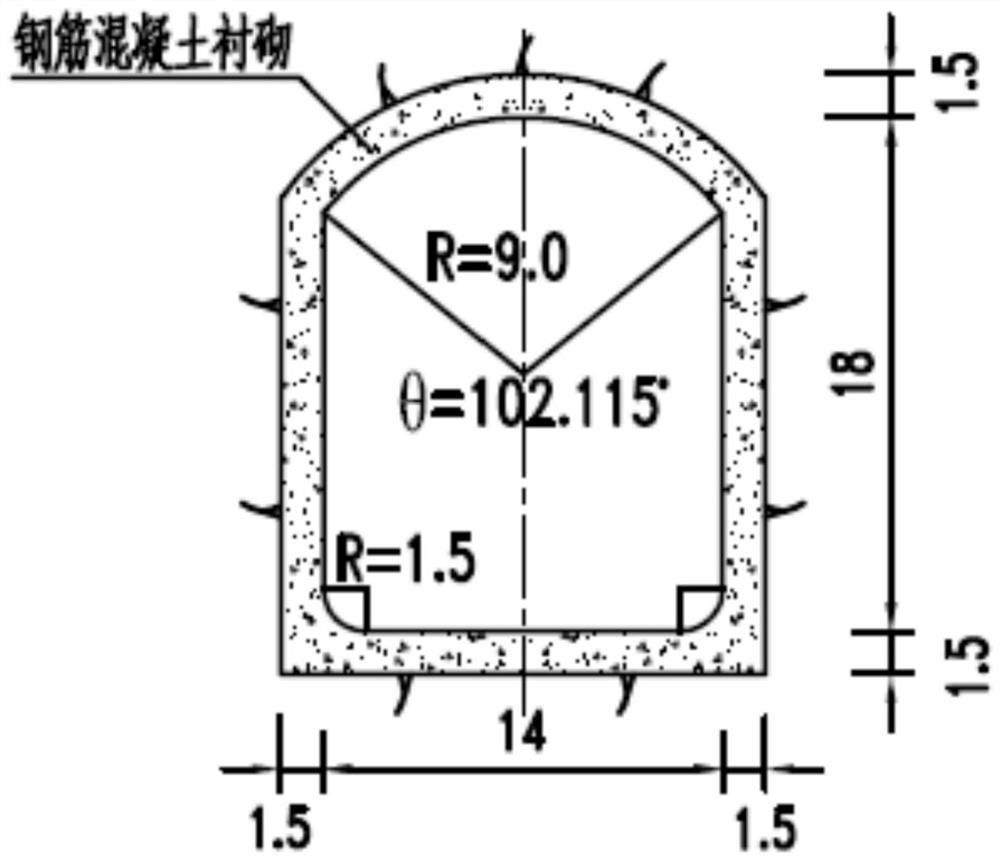

[0102] 3 # Optimal control of cooling through water for the 0.8m-thick A-type lining concrete of the first warehouse of the non-pressure gentle slope section of the spillway tunnel

[0103] For the 0.8m thick A-type lining structure of the gentle slope section of the spillway tunnel Figure 10 , the city gate tunnel-shaped section, along the axis of the flood discharge tunnel, set up circular construction joints every 9m, Class II surrounding rock, concrete strength C 90 35. The concrete is poured in two phases: first the side wall arch, then the floor. Here we introduce the optimal control of water cooling for side arch lining concrete pouring.

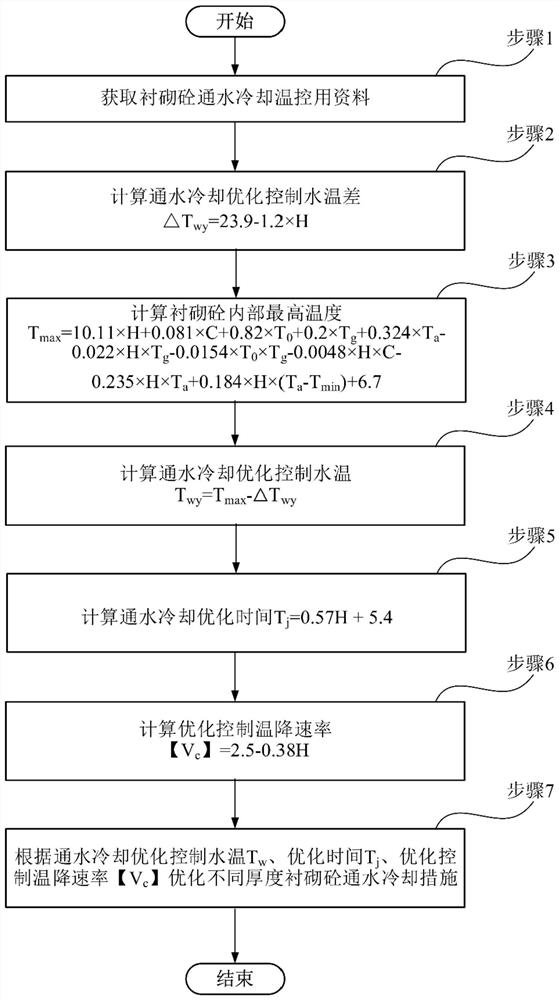

[0104] Such as figure 2 As shown, the optimal water temperature difference water cooling temperature control method for lining concrete with different thicknesses provided in this embodiment includes the following contents:

[0105] Step 1. Analyze the data related to water cooling and temperature control of lining concrete, i...

Embodiment 2

[0125] 3 # Optimal control of cooling through water for 1.0m-thick B-type lining concrete in the 11th warehouse of the non-pressure gentle slope section of the spillway tunnel

[0126] For the 1.0m-thick B-type lining structure of the 11th storehouse on the gentle slope section of the spillway tunnel, see Figure 11 , gate opening section, concrete strength C 90 35. Class III surrounding rock. The concrete is poured in two phases: first the side wall arch, then the floor. Here we introduce the optimal control of water cooling for side arch lining concrete pouring.

[0127] Such as figure 2 As shown, the optimal water temperature difference water cooling temperature control method for lining concrete with different thicknesses provided in this embodiment includes the following contents:

[0128] Step 1. Analyze the data related to water cooling and temperature control of lining concrete, including: collecting data related to temperature control and crack prevention of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com