Mass concrete construction device and method in marine environment

A large-volume concrete and marine environment technology, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve problems such as temperature cracks, affecting the appearance and normal operation of the project, and high heat of concrete hydration, so as to reduce the temperature difference between inside and outside, Realize the effect of temperature control and crack prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0030] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

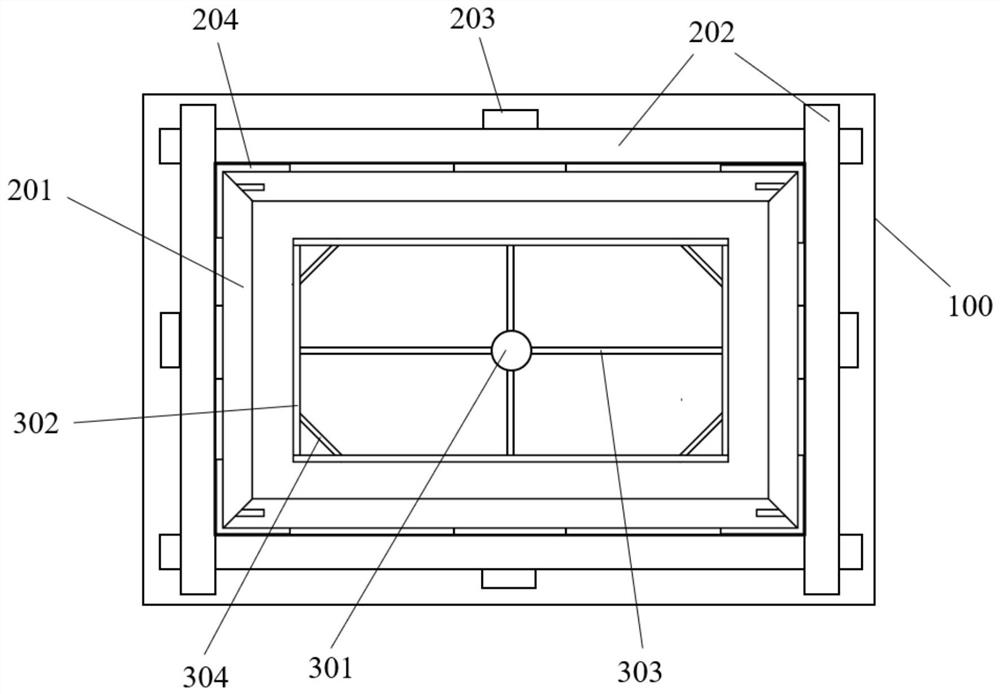

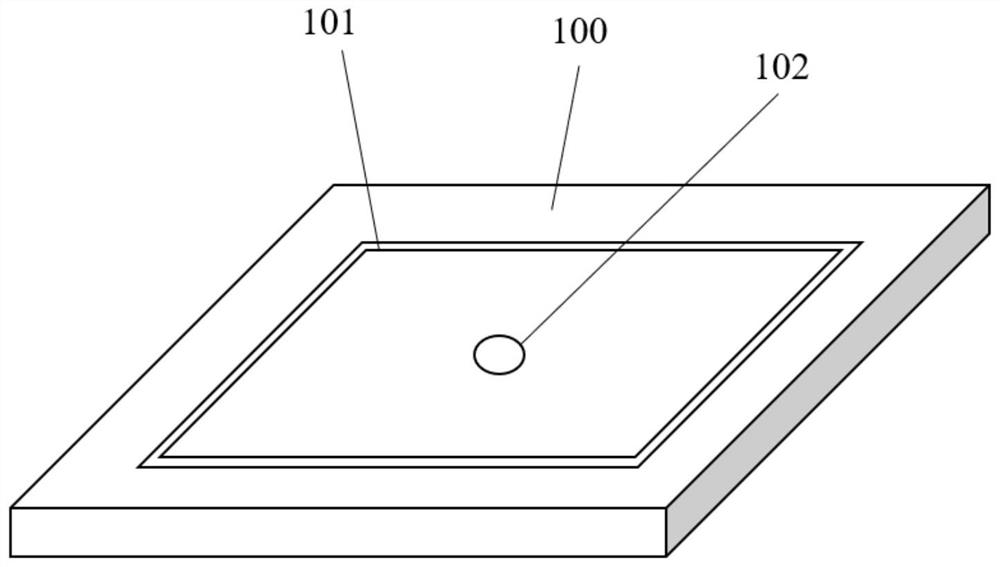

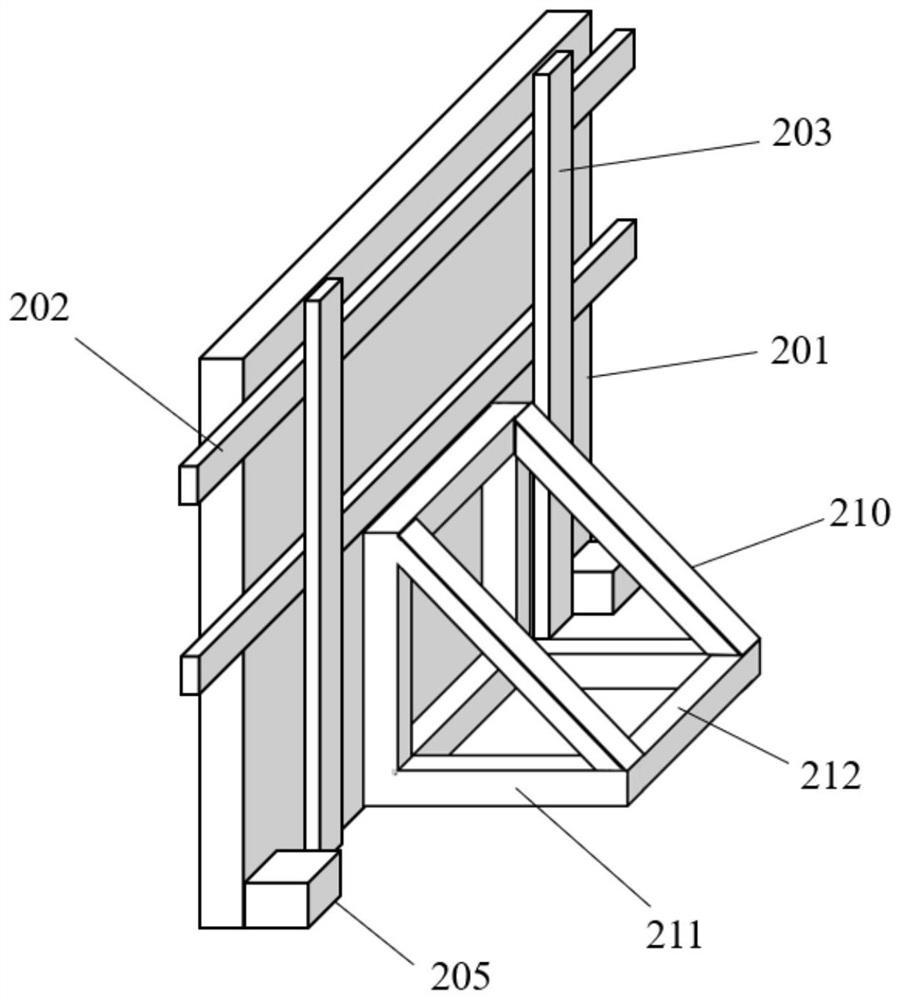

[0031] Such as Figure 1~5 As shown, the embodiment of the present application provides a large-volume concrete construction device in a marine environment, including:

[0032] The bottom plate 100 is provided with a positioning groove 101 and a positioning ring 102 on its surface;

[0033] Vertical formwork assembly 200, which includes a plurality of templates 201 and a fastening assembly, the multiple templates 201 are interlocked to form a concrete pouring space, and the fastening assembly includes multiple sets of horizontal fastening groups and multiple vertical fasteners 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com