Close-range image splicing method based on long-strip-shaped checkerboard calibration board

An image stitching and checkerboard technology, which is applied to the details of image stitching, graphic image conversion, image enhancement, etc. Insensitive, universal, and scalable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

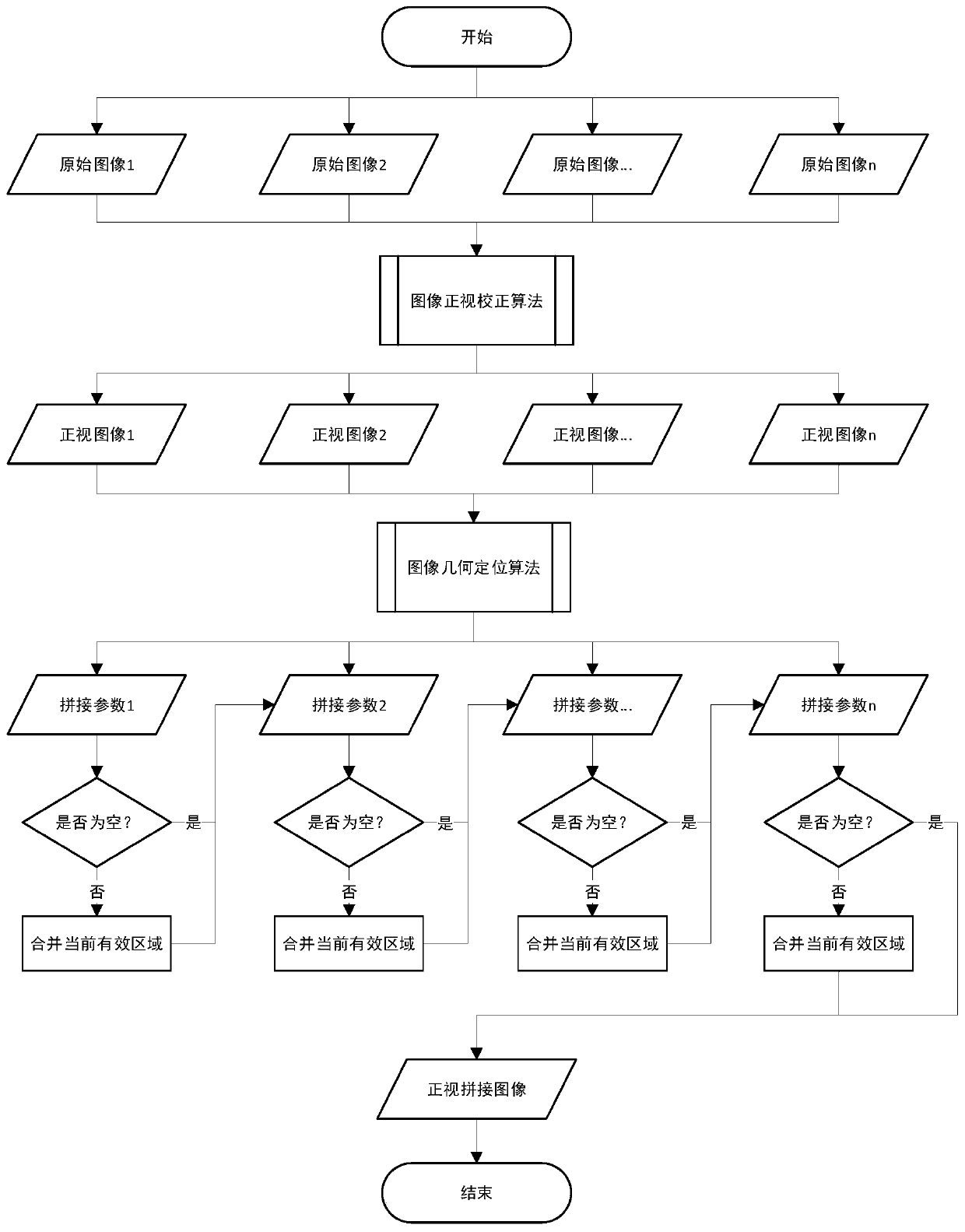

Method used

Image

Examples

Embodiment 1

[0073] In order to verify the splicing method of the present invention, the installation method is adopted in the embodiment, and the calibration plate is installed in the shooting picture, and a total of 6 pictures are taken to ensure that adjacent pictures overlap at least one group of concentric circles.

[0074] Such as Figure 5(a)-5(b) It is the local image of each stage with serial number 1 actually measured by the method of the embodiment of the present invention. The positioning mark of the local image of each stage with this serial number is 5, and the relevant information of the stitching parameters is: stitching has occurred, and the effective area of stitching is 840×560, corresponding to perspective transformation The matrix (with two decimal places) is:

[0075]

[0076] Such as Figure 6(a)-6(b) It is the local image of each stage with serial number 2 actually measured by the method of the embodiment of the present invention. The positioning mark of the l...

Embodiment 2

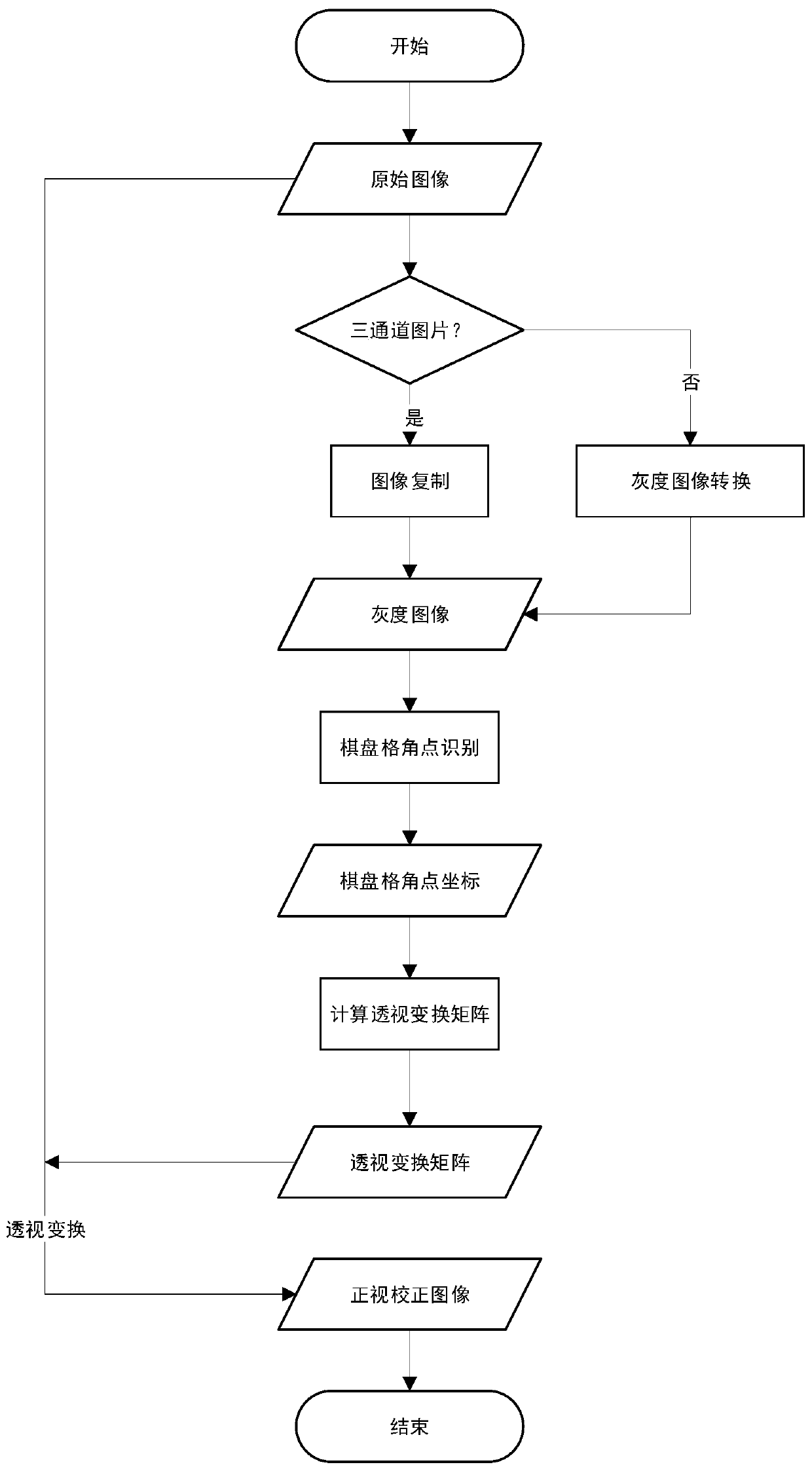

[0098] The image preprocessing process is as follows Figure 12 shown. Firstly, grayscale processing is performed on the original image to obtain a grayscale image to improve image processing efficiency. Then check the corners of the checkerboard on the grayscale image to obtain the pixel coordinates of the corners of the checkerboard to prepare for image projection transformation. Finally, the perspective projection transformation is carried out, and the front view correction is carried out to obtain the front view image.

[0099] After preprocessing the image of the checkerboard, the crack image is processed according to the same processing parameters, and finally the front view image is obtained, such as Figure 13 shown.

Embodiment 3

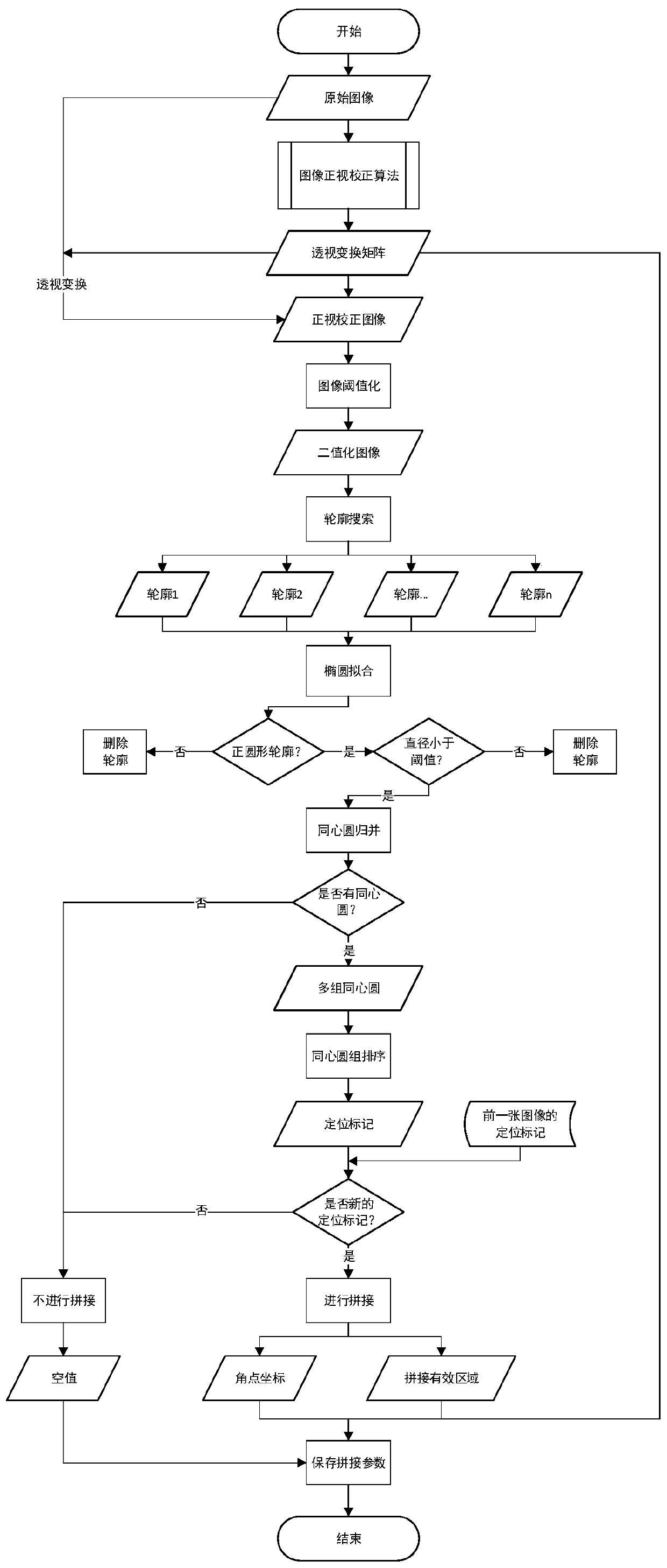

[0101] The principle of the image geometric positioning algorithm in the present invention is a coding registration algorithm, and the images can be registered according to the coding rules of the calibration board, and the present invention proposes a "coding registration" algorithm accordingly. The code registration algorithm divides the crack image into multiple regions according to the concentric circle codes that come with the calibration plate. For adjacent images, the regions with the same code are overlapping regions. Based on this, the images can be registered, such as Figure 14 shown.

[0102] The checkerboard coding calibration board adopts the middle concentric circles for coding, and the coding of the concentric circles depends on the number of concentric circles, and the order along the movement direction is "5-4-3-2-5-4-3-2-···" . According to this, the overlap of one concentric circle encoding is satisfied during shooting, and the registration can be performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com