A kind of graphene composite hydrogel and its preparation and application

A graphene composite and composite hydrogel technology, which is applied in the preparation/purification of carbon, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problem of weakened energy storage capacity and insufficient flexibility of all-solid supercapacitors, etc. problem, to achieve the effect of improved capacitance performance, good cycle stability, and fast electron transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

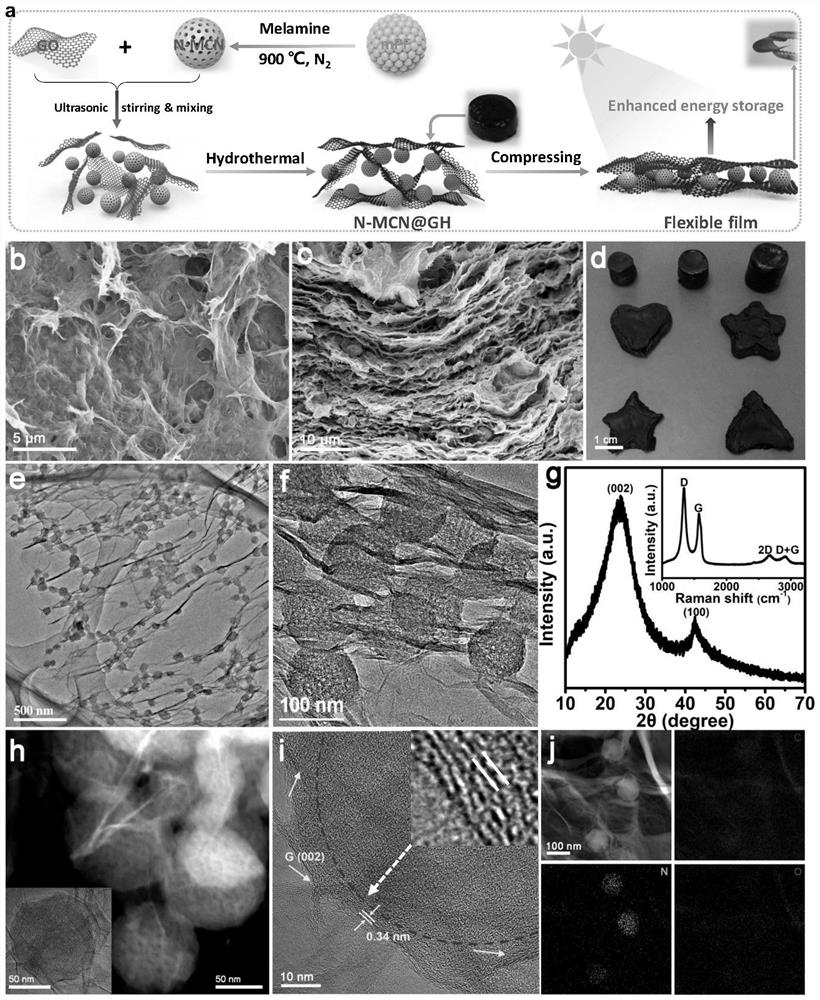

[0036](1) Dissolve 1.8g of phenol into 45mL of sodium hydroxide aqueous solution (1M), and mix with 6.3mL of formaldehyde solution (37wt%), add 45mL of F127 solution with a concentration of 64mg / mL, heat to 66°C and stir for 2 hours , followed by adding 150 mL of water to continue the reaction for 18 hours. After the reaction is complete, dilute the solution 3 times and put it into a hydrothermal kettle at a high temperature of 130°C for 24 hours to obtain phenolic resin prepolymer nanospheres. After washing and drying, they are calcined with melamine at 900°C for 2 hours to obtain nitrogen-doped mesoporous carbon nanospheres.

[0037] (2) Add 1 mg of the above-mentioned mesoporous carbon nanospheres to 1 mL of graphene oxide solution containing 2 mg / mL, and conduct ultrasonic treatment with a probe for 1 h to obtain a uniform dispersion.

[0038] (3) Sodium ascorbate solution (50 μL, concentration 1M) was added to the dispersion in step (2), and hydrothermally reacted at 100...

Embodiment 2

[0041] According to Example 1, the mass of the mesoporous carbon nanospheres in step (2) was modified to 2 mg, and the rest were the same as in Example 1 to obtain a graphene composite (N-MCN@GH) hydrogel.

[0042] Pure graphene (GH) hydrogel is the same as Example 1 except that no mesoporous carbon nanospheres are added.

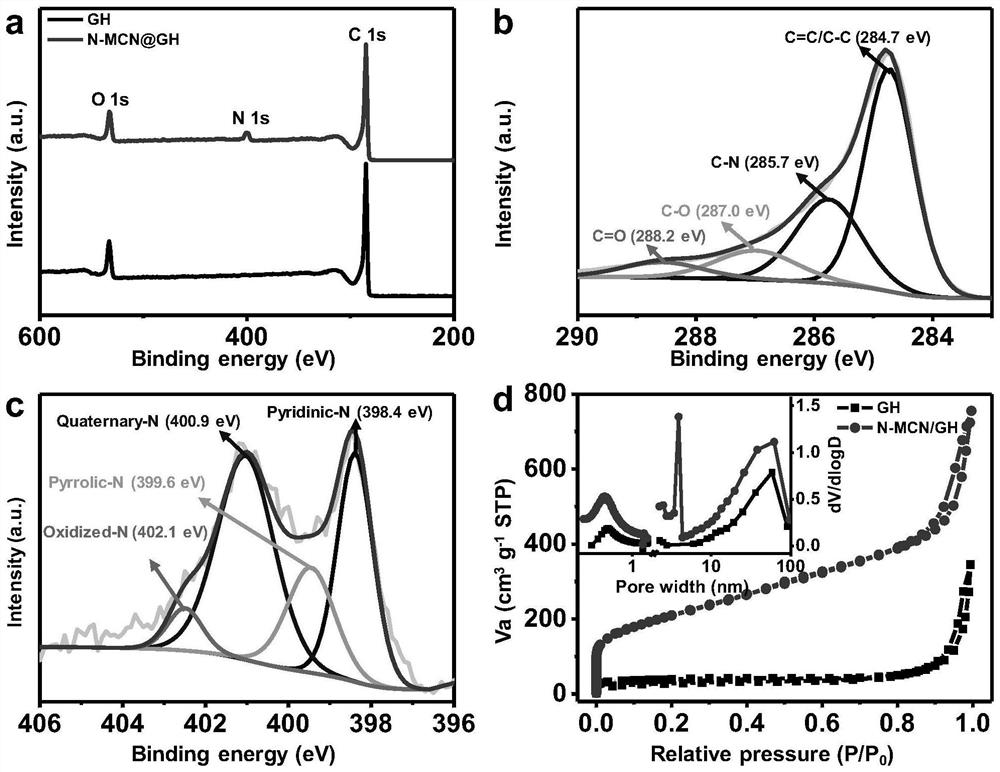

[0043] figure 2 a-c shows the peak of nitrogen element, which proves that nitrogen-doped mesoporous carbon nanospheres are embedded in the graphene network, figure 2 d shows that the specific surface area of N-MCN@GH is 742m 2 / g, GH specific surface area is 125m 2 / g, which proves that the addition of mesoporous carbon nanospheres can effectively increase the specific surface area of the composite, which is conducive to the immersion of the electrolyte.

Embodiment 3

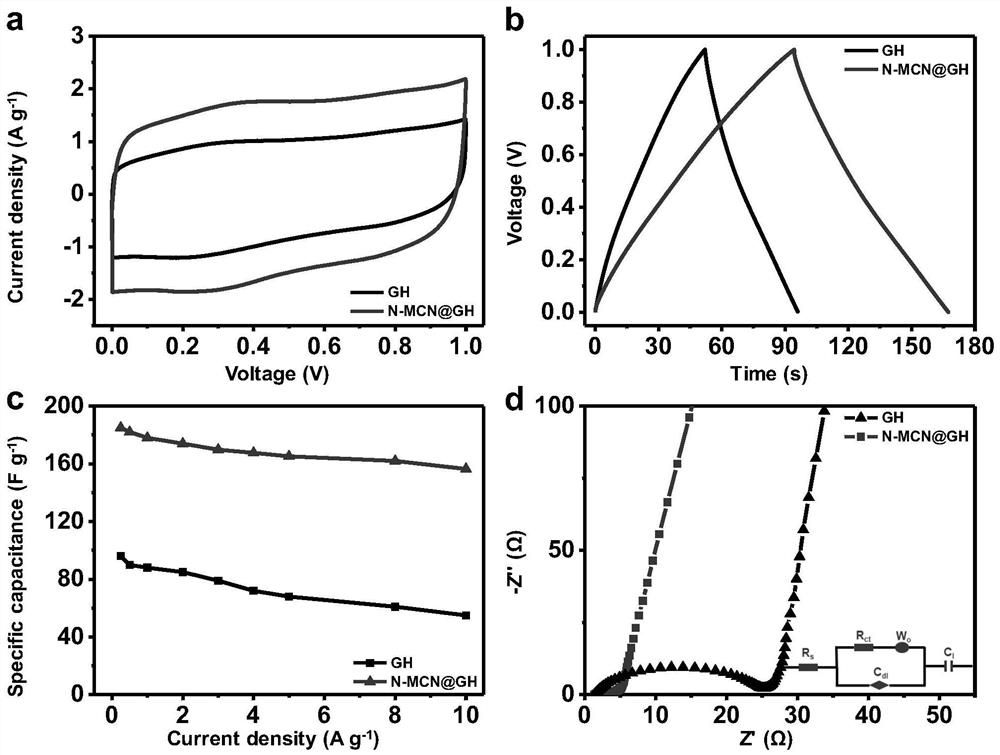

[0045] The graphene composite hydrogel in embodiment 2 is directly pressed on the current collector stainless steel mesh (500 mesh) under 10MPa pressure, and utilizes polymer electrolyte PVA / H 2 SO 4 (The PVA concentration is 10wt%, the sulfuric acid concentration is 1M), the electrolyte is coated on the electrode, and after drying, the two electrodes are stacked to form a flexible all-solid supercapacitor.

[0046] The pure graphene (GH) hydrogel in Example 2 was assembled into a GH supercapacitor according to the above method.

[0047] Place the above capacitor under the solar simulator (0.36W / cm 2 ), and a low-temperature environment was simulated by a constant temperature water bath under the capacitor, and its electrochemical performance was tested under light conditions, such as Image 6 As shown, it shows that the N-MCN@GH electrode has a stronger absorption capacity for light, which is because the embedding of mesoporous carbon nanospheres can improve the absorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com