Agricultural aquaculture oxygenation equipment

A technology of aeration equipment and agriculture, applied in fish farming, animal husbandry, application, etc., can solve the problems of death and single function of aerator, so as to improve the living environment, reduce the probability of fish death, and avoid fish effect of death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

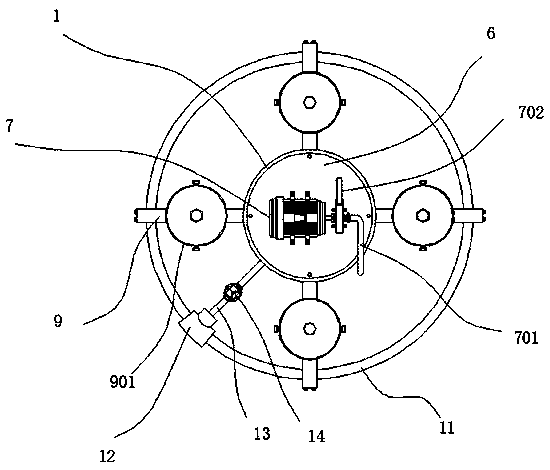

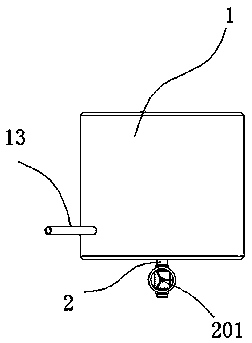

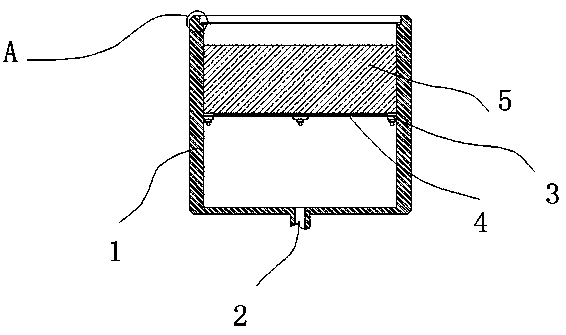

[0040] refer to figure 1 The shown aeration equipment for agricultural breeding includes a water booster tank 1, which is made of stainless steel and has a wall thickness of 3mm. The first water outlet pipe 2 is equipped with a ball valve 201 on the first water outlet pipe 2, the ball valve adopts a manual ball valve, and a plurality of ear parts 3 are welded inside the water booster pipe 1, and a plurality of the ear parts 3 is equipped with a grid net 4, a filter material 5 is laid above the grid net 4, a stepped surface 101 is processed on the top of the water booster tank 1, and a top is supported by the stepped surface 101. Cover 6, the top cover 6 and the water booster tank 1 are fixed by screws, and a pump body 7 is fixed by screws on the top of the top cover 6, and the pump body 7 is connected with an inlet pipe 701 and an outlet pipe 702 , the water inlet pipe 701 extends downwards into the pond, and the lower end of the water inlet pipe 701 is more than 20cm away fr...

Embodiment 2

[0042] refer to Figure 7 As shown, two brackets 202 are symmetrically arranged at the bottom of the water booster tank 1. A water spray pipe 203 is installed between the two brackets 202. The diameter of the water spray pipe 203 is from top to bottom. gradually decreases, a hose 204 is installed between the water spray pipe 203 and the first outlet pipe 2, and two pin shafts 205 are welded on the outer wall of the water spray pipe 203, and the pin shafts 205 pass through Nuts 206 are installed between the brackets 202, and the structure of the water spray pipe is gradually reduced in diameter downwards, which increases the flow velocity of the water, and the water will generate a greater thrust when it hits the water surface downwards. After contact, a large amount of oxygen will be generated to supplement the oxygen content in the water. The angle of the water spray pipe can be adjusted by rotating the pin shaft along the bracket. When the water sprayed by the water spray pi...

Embodiment 3

[0044] refer to Figure 8 As shown, a rubber strip 8 is embedded in the stepped surface 101, and the top cover 6 is assembled to press the rubber strip 8. The rubber strip mainly increases the sealing between the top cover and the water pressurized tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com