A shell breaking machine based on pretreated walnuts

A technology of shell breaking machine and pretreatment, applied in the fields of shell removal, pod removal, food science, etc., can solve problems such as reducing the added value of products, and achieve the effect of ensuring food safety, avoiding jamming, and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

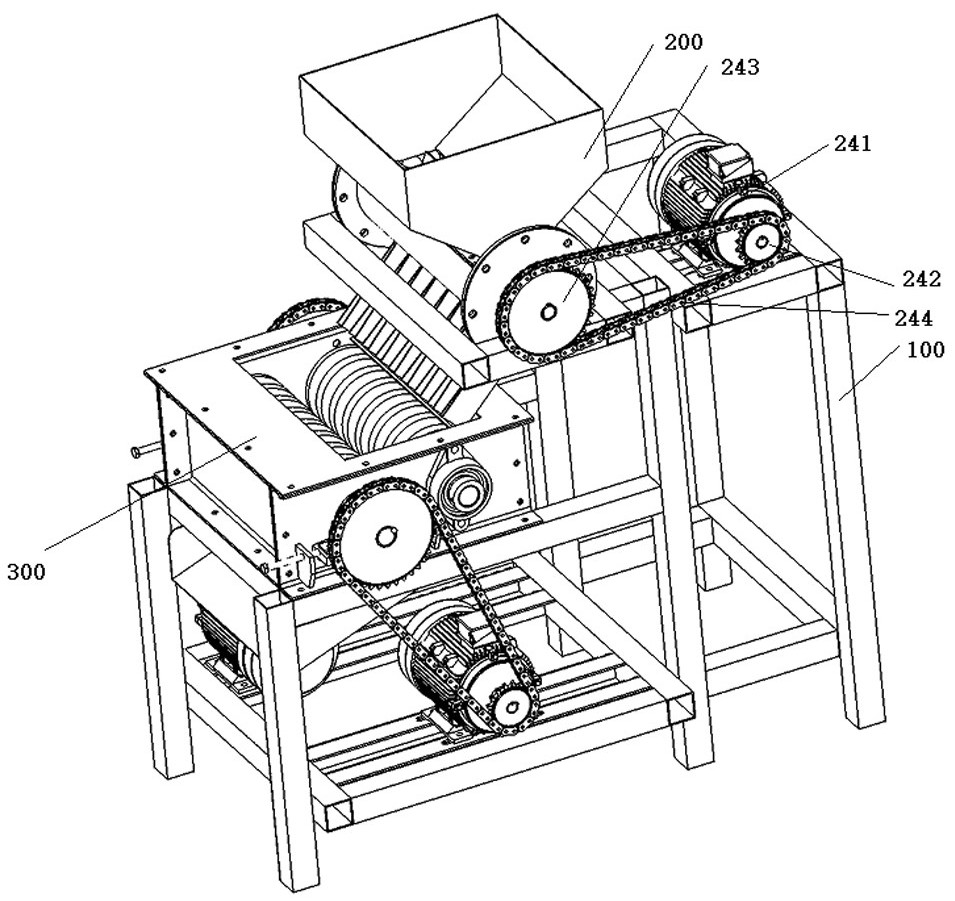

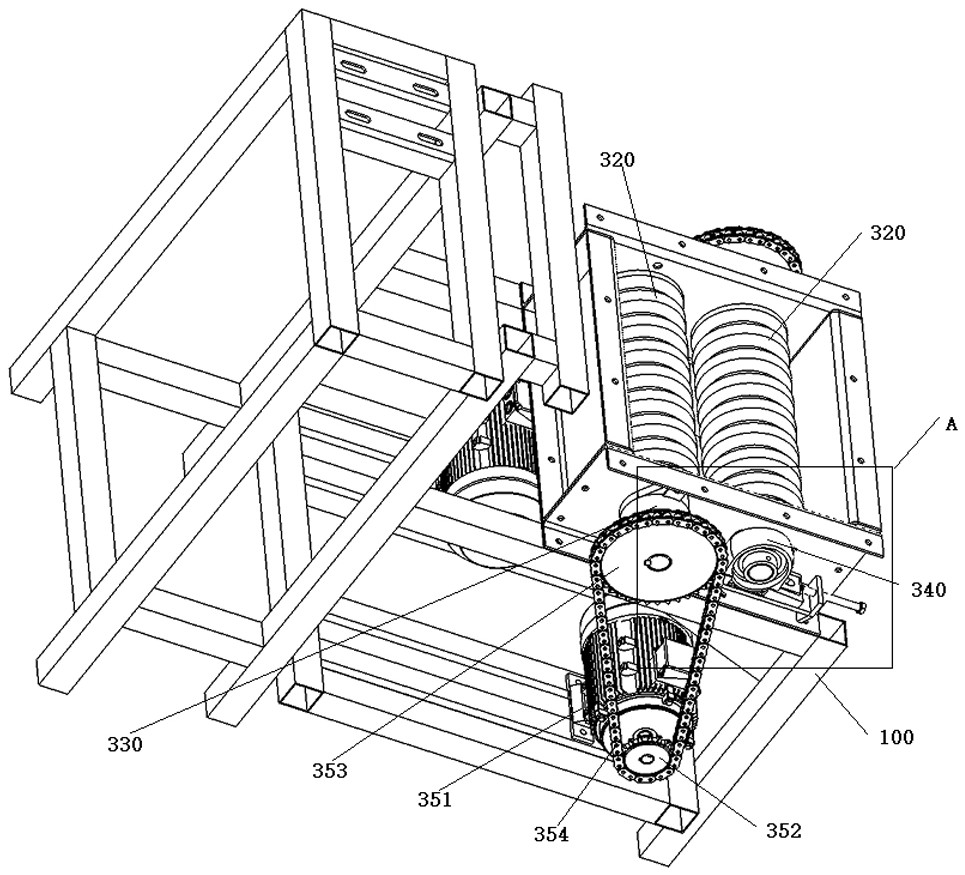

[0039] like Figure 1 to Figure 5 As shown, a shell breaking machine based on pretreated walnuts includes a frame 100, an impeller feeding device 200 and a pair of roller extrusion devices 300, and the impeller feeding device 200 and the pair of roller extrusion devices 300 are all installed on the frame 100 Above, the walnuts that have been pretreated by scoring and size classification are put into the impeller feeding device 200, and then fed to the roller extrusion device 300 for crushing and cracking.

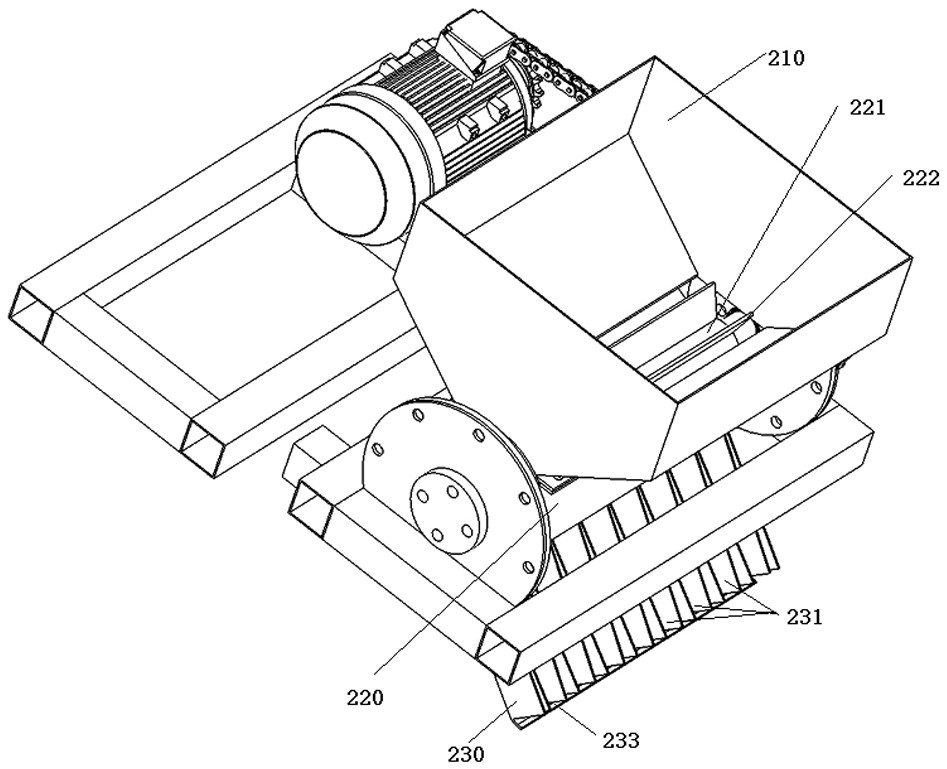

[0040]The above-mentioned impeller feeding device 200 comprises a feeding hopper 210, a material distribution cylinder 220 and a feed plate 230, the material distribution cylinder 220 is cylindrical, and the material distribution cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com