A multifunctional four-jaw chuck for machine tools

A four-jaw chuck, multi-functional technology, applied in the direction of the chuck, etc., can solve the problem of not being able to clamp elliptical and rectangular disc-shaped parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

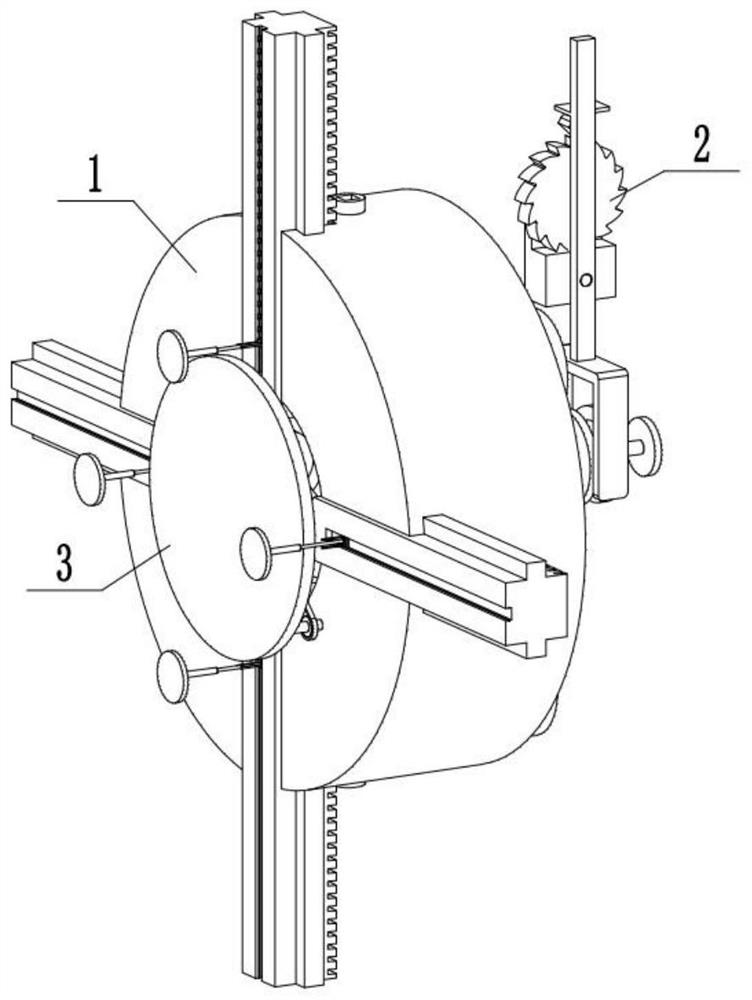

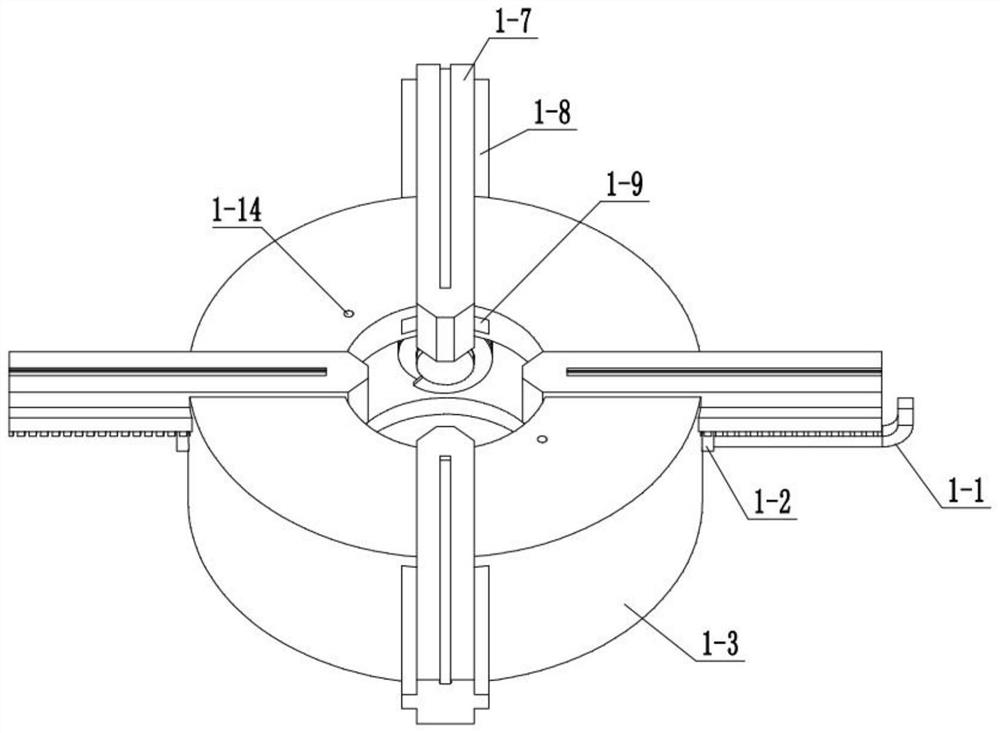

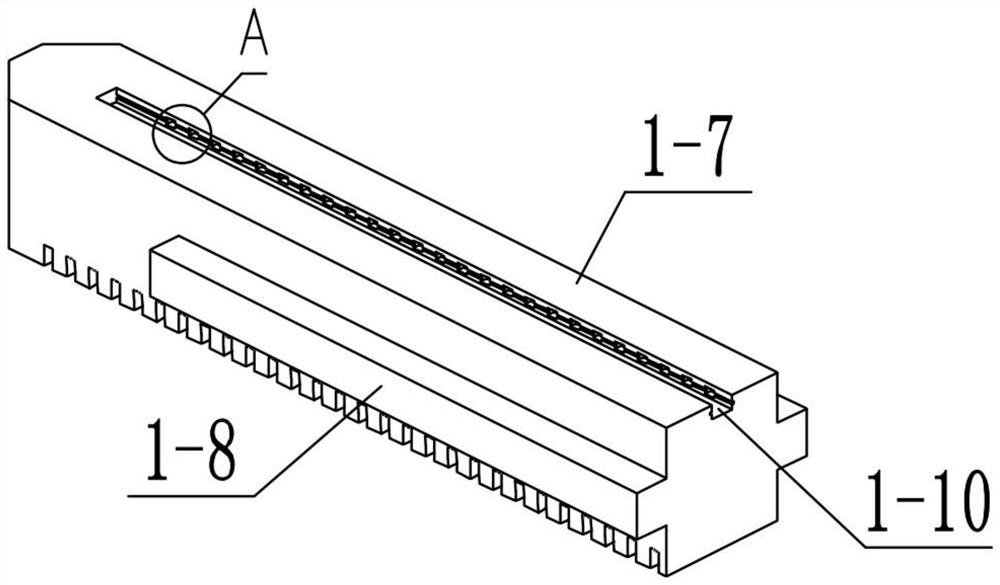

[0031] Combine below Figure 1-17 Describe this embodiment, a multifunctional four-jaw chuck for machine tools, including a clamping assembly 1, an adjusting assembly 2, and a disc-shaped part clamping assembly 3, and the clamping assembly 1 includes a square wrench 1- 1. Adjusting cylinder 1-2, fixture shell 1-3, bevel gear 1-4, helical gear shaft 1-5, helical tooth 1-6, claw 1-7, claw carriage 1-8, claw slide Rail 1-9, chute Ⅰ 1-10, positioning hole 1-11, chute Ⅱ 1-12, friction groove 1-13 and threaded through hole 1-14, square wrench 1-1 and four adjustment cylinders 1-2 all For clearance fit, the four adjusting cylinders 1-2 are all connected to the fixture shell 1-3 in rotation, the four adjusting cylinders 1-2 are respectively connected to the four bevel gears 1-4, and the four bevel gears 1-4 are respectively connected to the four bevel gears. The four helical tooth shafts 1-5 are connected to each other, the four helical tooth shafts 1-5 are respectively connected to ...

specific Embodiment approach 2

[0035] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the disc-shaped part clamping assembly 3 includes a lifting plate 3-1, a threaded shaft I3-2, a lifting knob 3-3, and a pulley I3-4 , belt 3-5, pulley Ⅱ 3-6, threaded shaft Ⅱ 3-7, transposition lever 3-8, slanting block 3-9, slanting block housing 3-10, spring Ⅲ 3-11, slanting block housing carriage 3- 12. The lower threaded column 3-13, the upper threaded cylinder 3-14 and the limit plate 3-15, the lifting plate 3-1 is rotationally connected with the threaded shaft Ⅰ 3-2, the threaded shaft Ⅱ 3-7, the threaded shaft Ⅰ 3-2, the threaded shaft Shaft II 3-7 is threadedly connected with two threaded through holes 1-14 respectively, lifting knob 3-3 and pulley I 3-4 are connected with threaded shaft I 3-2, pulley I 3-4, belt 3-5, belt The pulley II3-6 is connected with the belt pulley, the pulley II3-6 is connected with the threaded shaft II3-7, the eight transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com