Leek root and peel removal machine

A technology of peeling machine and leek, which is applied in the direction of solid separation, separating solid from solid with air flow, metal processing, etc., which can solve the problems of low work efficiency, poor working environment for workers, and increased labor costs, and improve work efficiency. Efficiency, prevention of random changes in the position of leeks, and the effect of flexible positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

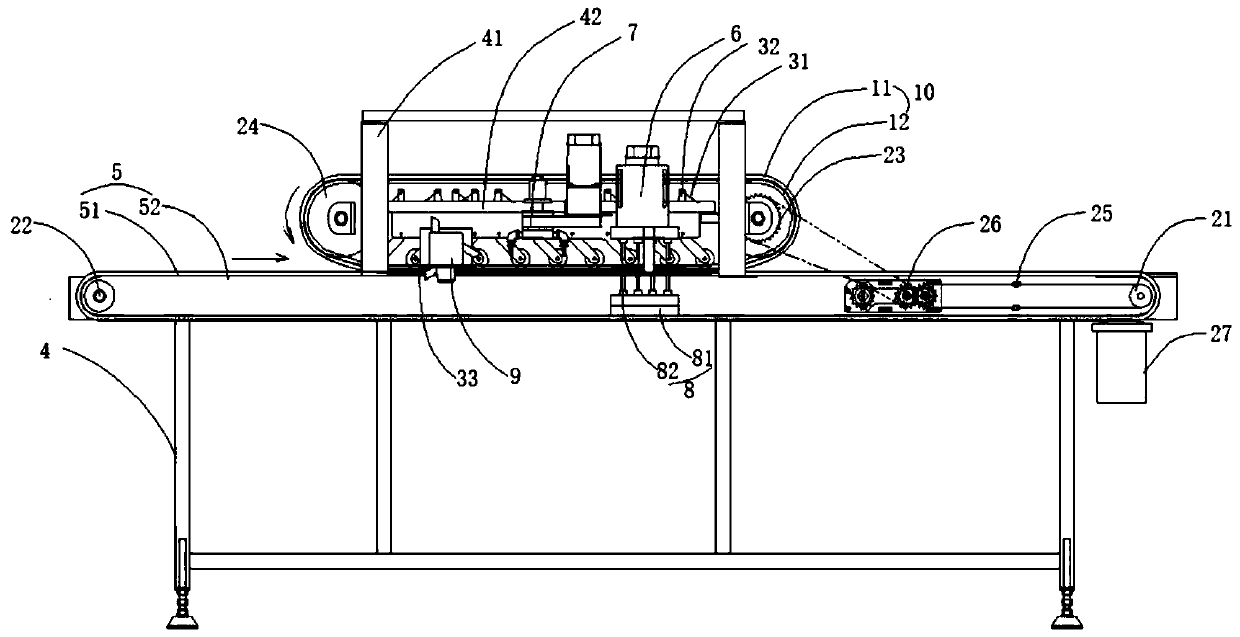

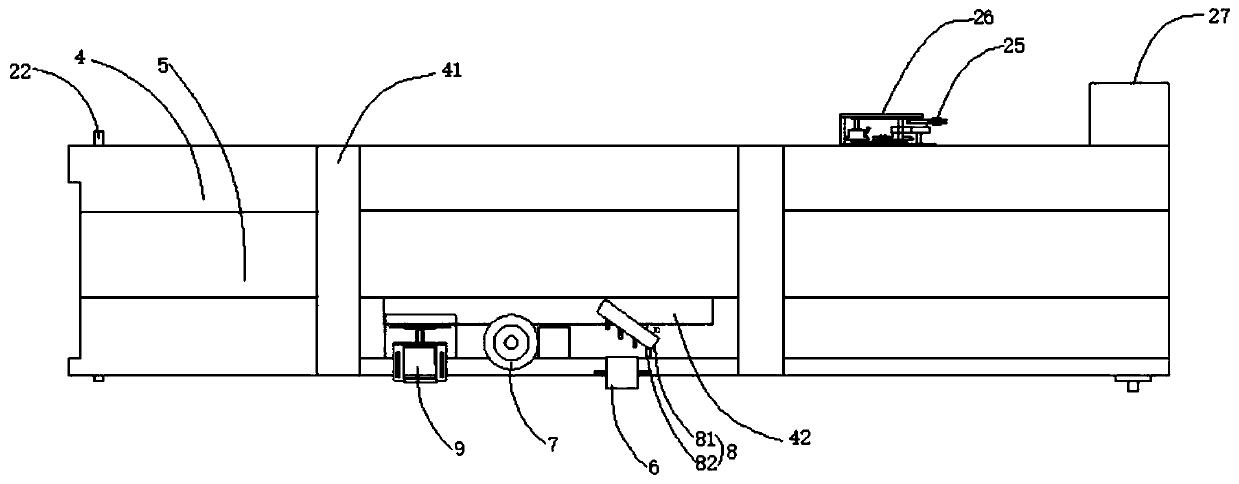

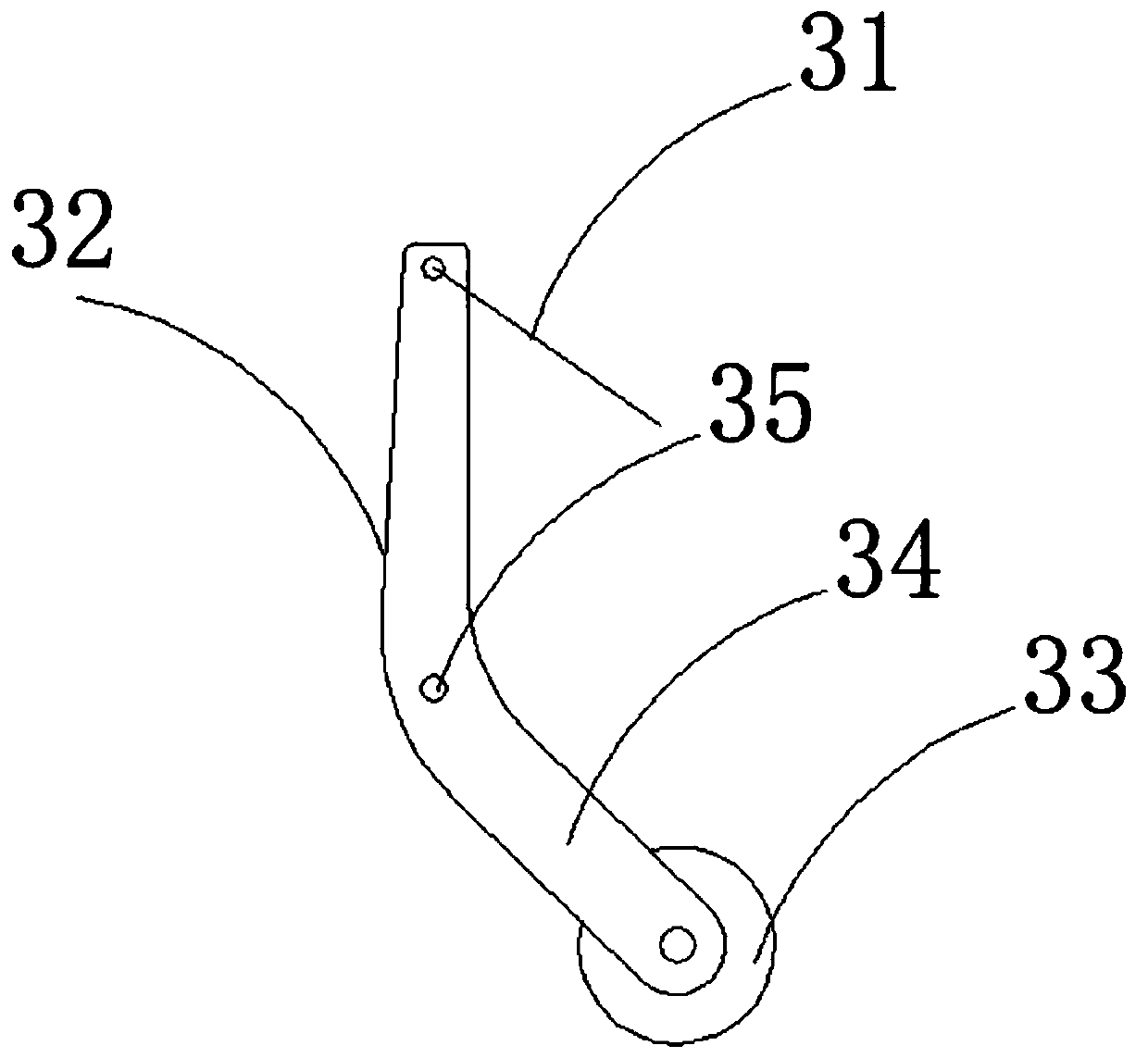

[0037] A kind of chive root peeling machine, it is characterized in that: comprise frame body 4 and be arranged on described frame body 4 upper sponge belt 10, lower sponge belt 5, transmission device, cutter device 9, rotary air blowing device 7 , swing bar device 6, air blowing device 8, according to the transmission direction of the transmission device, the cutter device 9 is arranged at the forefront, followed by the rotating air blowing device 7, and the rearmost is the swing bar device 6 and the air blowing device 8. The air blowing device 8 is provided with two groups corresponding up and down, and the swing rod 61 of the swing rod device 6 is arranged in the middle of the corresponding two groups of blowing devices 8 .

[0038] As preferably, the upper sponge belt 10 includes an upper sponge 11 and an upper belt 12, and the lower sponge belt 5 includes a lower sponge 51 and a lower belt 52, and the sponge can be pasted on the belt with glue, etc., and the upper sponge b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com