A kind of semi-rigid bridge anti-collision guardrail

A kind of anti-collision guardrail, semi-rigid technology, used in bridges, bridge construction, bridge parts and other directions, can solve the problem of insufficient anti-collision performance of the anti-collision guardrail, achieve the effect of high bearing capacity and prevent large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

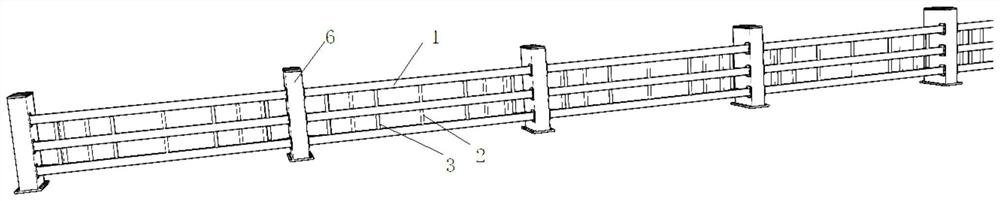

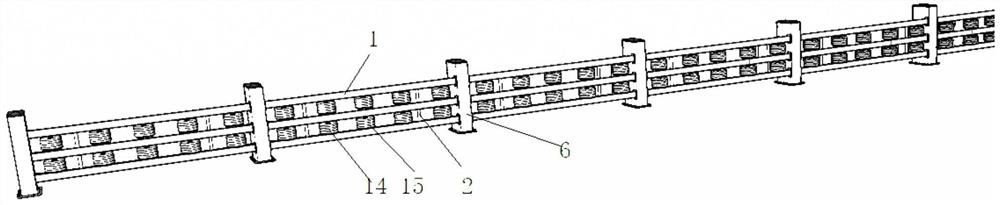

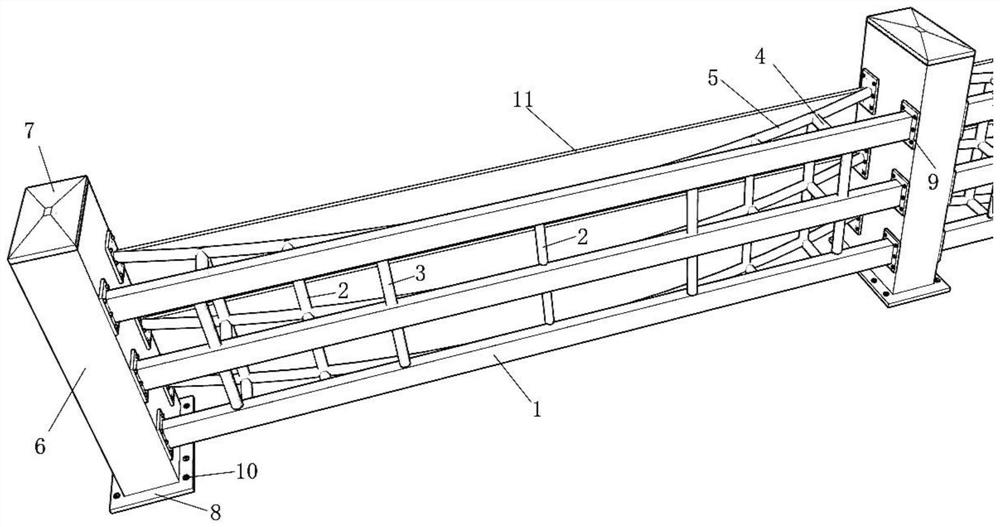

Embodiment 1

[0050] The semi-rigid bridge anti-collision guardrail of the present embodiment comprises steel longitudinal beam 1, horizontal link 2, steel pipe beam 3, steel pipe column 4, arched steel pipe 5, steel column 6, column cover 7, column foot 8, steel backing plate 1 9. Nut 10, cable 11, steel backing plate 2 12, anti-collision roller 1 14, anti-collision roller 2 15, I-shaped stiffening plate 18, cable clamp 19, hole nut 20, spiral pipe 21 and bolt 22. See details Figure 1-6 . Steel longitudinal beam 1, horizontal connection 2, steel pipe beam 3, steel pipe column 4, arched steel pipe 5, steel backing plate-9 and steel backing plate-12 jointly form the guardrail steel skeleton structure. The steel longitudinal beam 1 is a hollow rectangular structure with a cross-sectional size of 20cm (length)×30cm (width), a thickness of 0.5cm, and a material of Q345 steel. The steel pipe crossbeam 3 is a circular pipe structure with an outer diameter of Φ8cm, a wall thickness of 3mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com