Disc connecting mechanism with multi-shaft sleeve supporting, rotary drilling rig and working method for rotary drilling rig

A technology of connecting mechanism and shaft sleeve, applied in drilling equipment and methods, drilling equipment, earthwork drilling and other directions, can solve the problems of mast guidance deviation, unstable swing, affecting the normal use of rotary drilling rig, etc., to reduce shaking, The effect of improving swing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

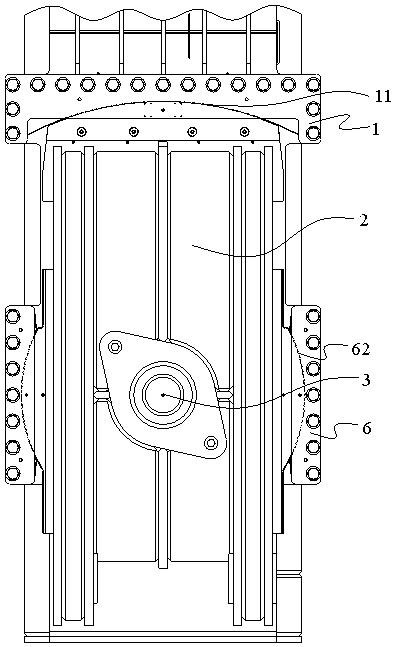

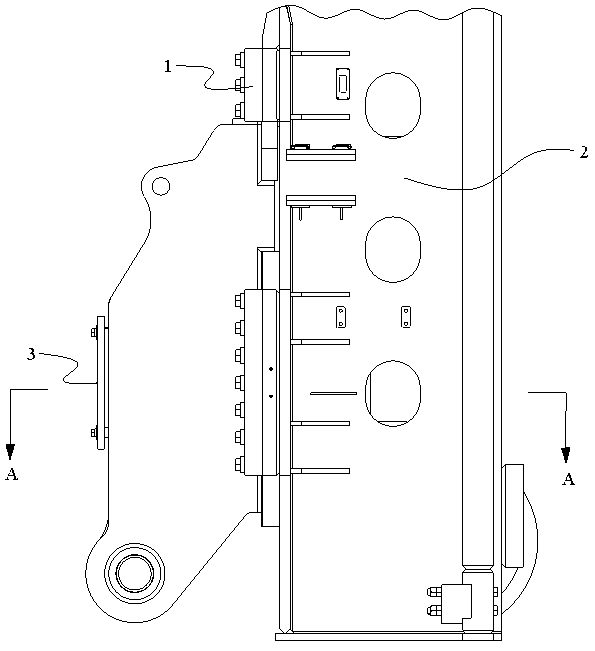

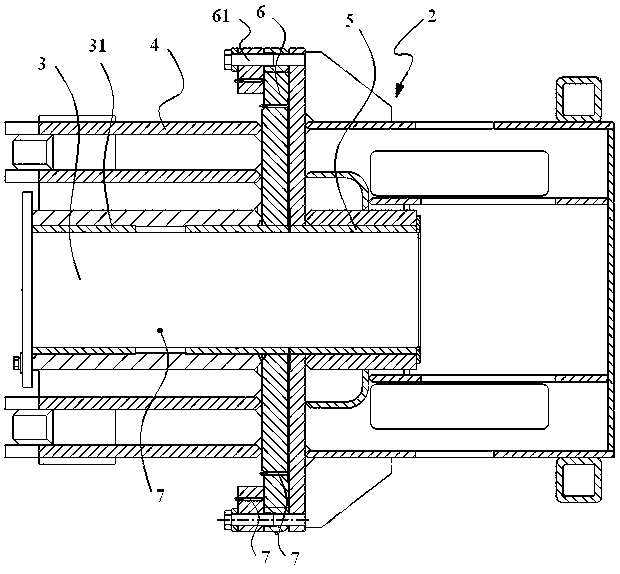

[0025] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment 1 provides a disc connection mechanism supported by multi-axis sleeves, including: a support frame 1 with a concave arc surface 11 facing downward, a drill mast 2 whose top is against the concave arc surface 11, and a vertically inserted The mandrel 3 of the drill mast 2 and the large disk 4 that is sheathed on the mandrel 3; the large disk 4 is suitable for driving the drill mast 2 to rotate around the mandrel 3 when rotating, so that the top of the drill mast 2 moves along the The concave arc surface 11 moves, that is, the drill mast 2 swings left and right. Specifically, during use, the drill mast is generally arranged vertically, and the mandrel is arranged horizontally on the drill mast.

[0026] Optionally, the top of the drill mast 2 is adapted to the concave arc surface.

[0027] The disc connection mechanism in Embodiment 1 drives the large disc to rotate through the luffing mechanis...

Embodiment 2

[0036] On the basis of Embodiment 1, this Embodiment 2 provides a rotary drilling rig, including: a luffing mechanism and a disc connection mechanism as described above; wherein the luffing mechanism is hinged to the disc connection mechanism, so Drive the big disc to rotate.

[0037] For the specific structure and implementation process of the disk connection mechanism, please refer to the relevant discussion of Embodiment 1, and details will not be repeated here.

Embodiment 3

[0039] On the basis of embodiment 1, this embodiment 3 provides a working method of the disk connection mechanism, the large disk of the disk connection mechanism is suitable for driving the drill mast to rotate around the mandrel when rotating, so that The top of the drill mast moves along the concave arc surface of the support frame. Wherein the big disc can be driven to rotate by the luffing mechanism.

[0040] For the specific structure and implementation process of the disk connection mechanism, please refer to the relevant discussion of Embodiment 1, and details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com