Arrangement for recirculating exhaust gas

A technology of exhaust gas recirculation and exhaust system, applied in the direction of exhaust gas recirculation, electrical control, charging system, etc., can solve the problem of material damage of the compressor, and achieve the effect of effective and safe droplet impact and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

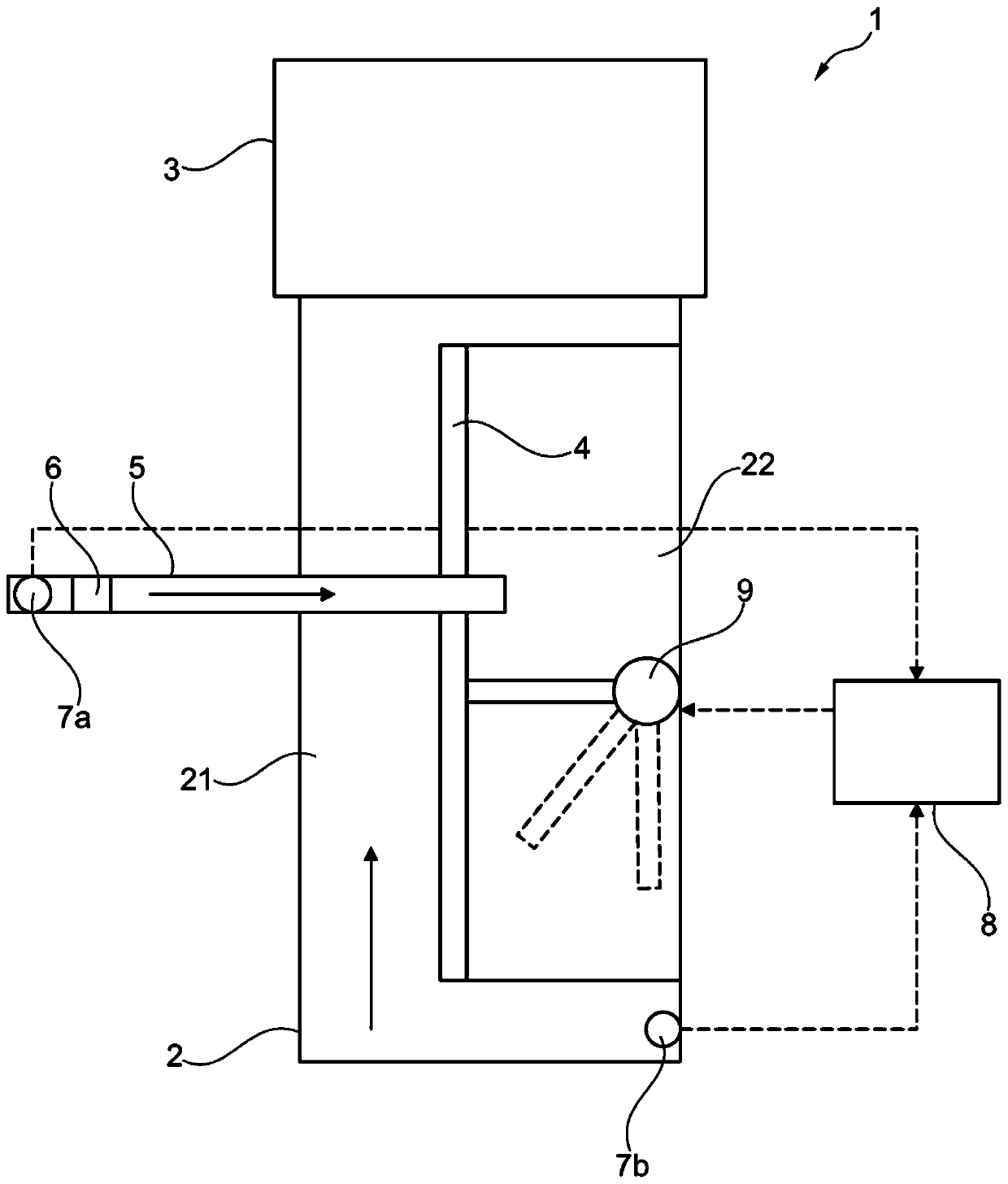

[0040] In one embodiment of arrangement 1 according to the invention, according to figure 1 , showing intake duct 2. Intake duct 2 delivers charge air to an internal combustion engine (not shown) of the motor vehicle. The compressor 3 compresses the charge air, which compressor 3 is provided in the flow path of the intake port 2 . Upstream of the compressor 3 , a partition wall 4 is provided in the intake duct, which divides the intake duct 2 into an outer tube 21 and an inner tube 22 in a defined portion ending immediately upstream of the compressor.

[0041] The walls of the inner tube 22 are formed by the partition wall 4 and the walls of the inlet duct 2 . In a preferred embodiment, the partition wall 4 is implemented so as to partially enclose the volume of the inner tube 22 . Therefore, the cross-section of the partition wall 4 is curved, ie curved in the flow direction of the exhaust gas. Alternatively, the cross section of the partition wall 4 can also be straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com