Shock absorbing pad for composite generator

A technology of shock absorbing pads and generators, applied in the direction of generators/motors, electrical components, electromechanical devices, etc., can solve the problems of energy collection, increase of building load, vibration energy dissipation, etc., to reduce generation channels and reduce noise , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

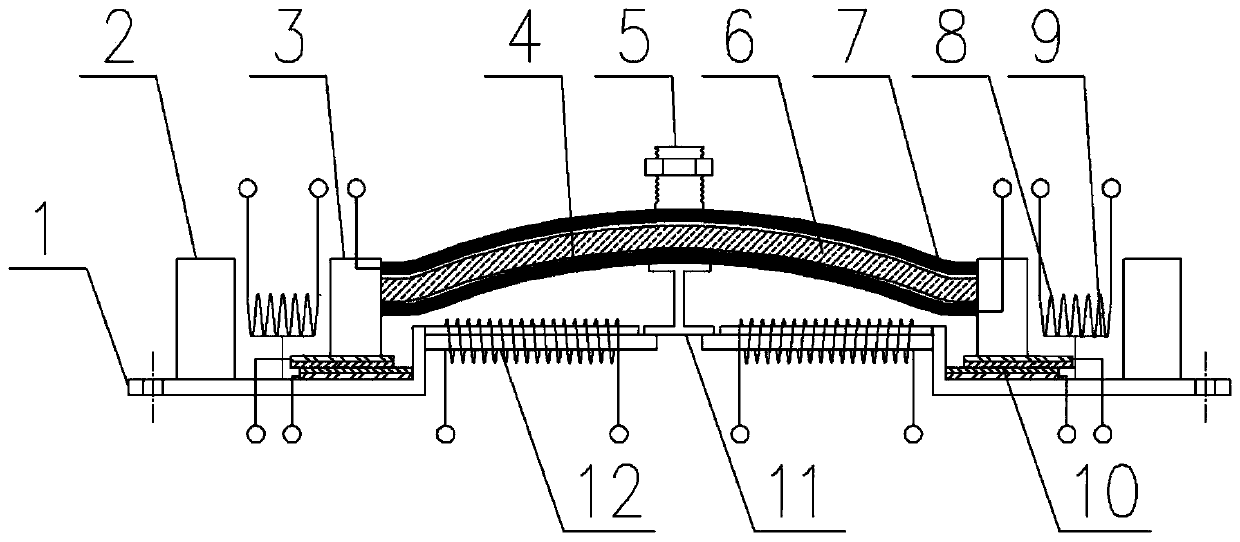

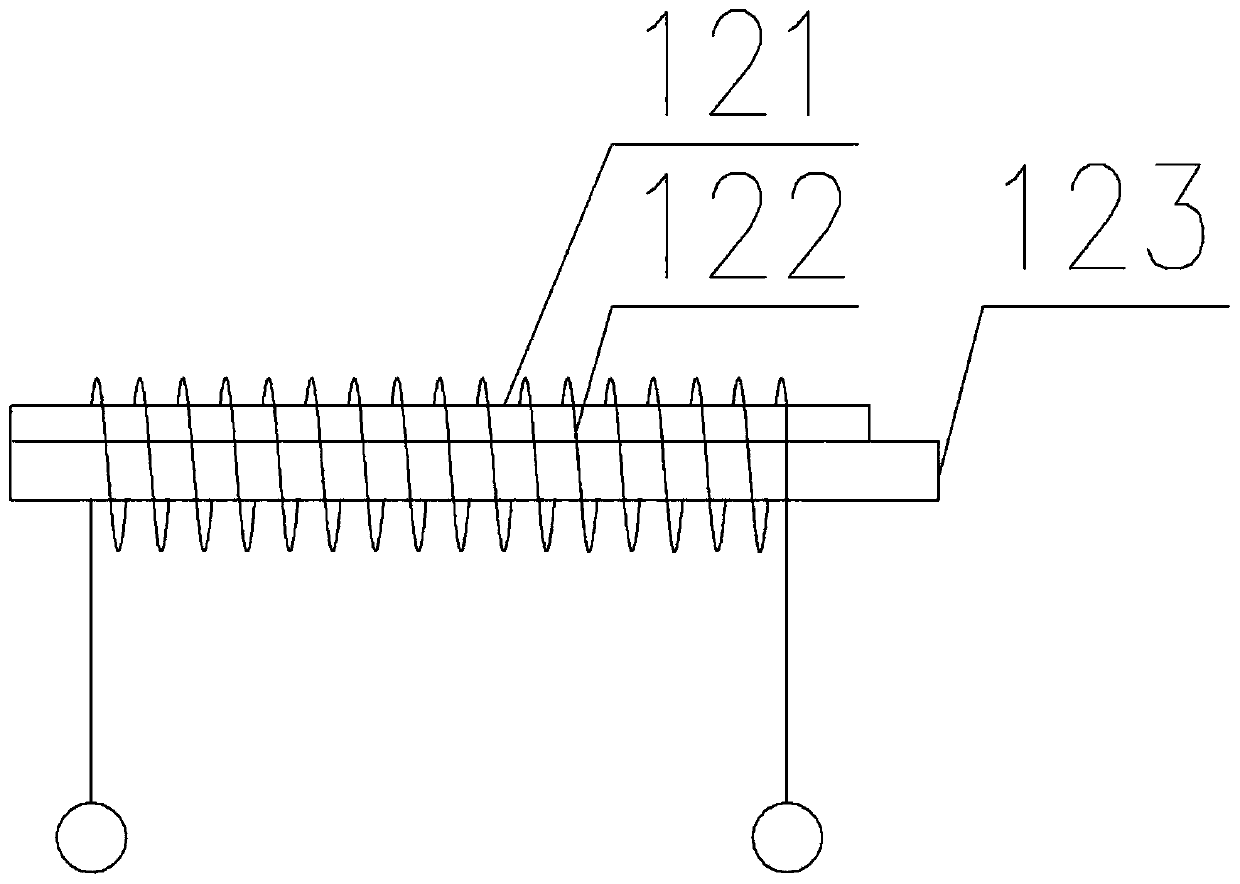

[0023] Such as figure 1 As shown, the embodiment of the present invention includes a bracket on which a piezoelectric component, a friction component 10 , an electromagnetic component and a magnetostrictive component 12 connected to a vibration device are arranged.

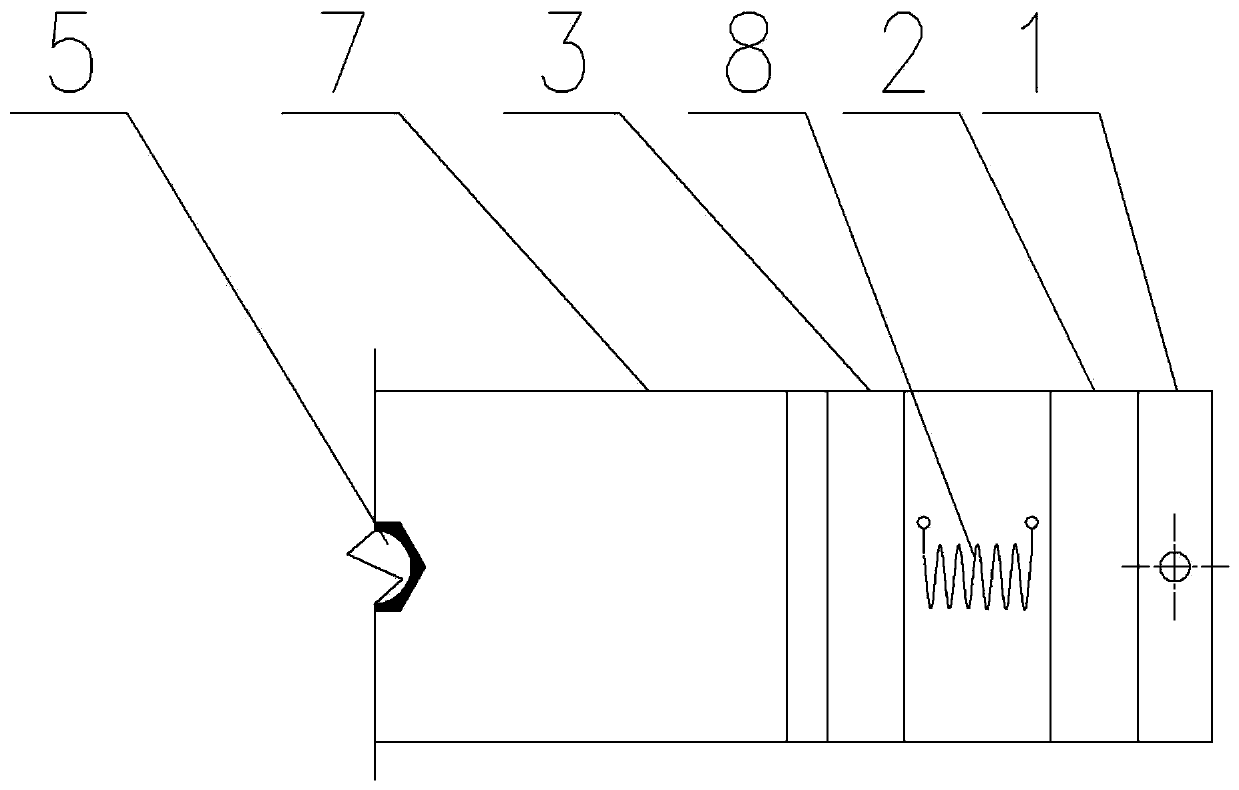

[0024] The piezoelectric assembly includes a piezoelectric material 6 with an arched structure and elastic steel plates 4 arranged on the upper and lower surfaces of the piezoelectric material 6, and a copper electrode is arranged between the elastic steel plate 4 and the piezoelectric material 6, so that An insulating layer 7 is provided between the copper electrode and the elastic steel plate 4 .

[0025] The two ends of the elastic steel plate 4 are respectively fixed with sliders 3, and the sliders 3 slide and fit on the bracket along the direction in which the piezoelectric material 6 extends; The steel plate 4 is fixed with connecting bolts 5, and the piezoelectric material 6 is externally connected to an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com