Antibacterial mask and manufacturing method thereof

A manufacturing method and mask technology, applied in clothing, clothing, protective clothing, etc., can solve the problem of masks without antibacterial function, and achieve the effect of solving no antibacterial function and realizing antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a kind of manufacture method of antibacterial face mask, it comprises the following steps:

[0022] (1) Mixing the inorganic nano-antibacterial material powder including at least nano-zinc oxide and nano-silver ion antibacterial powder with chitin / nano-anion powder to prepare antibacterial materials;

[0023] In this step, in order to achieve a durable and efficient antibacterial effect, the antibacterial material is a nanoparticle state material comprising a metal salt and chitin, which preferably consists of the following components by weight:

[0024] 5-30 parts of nano-zinc oxide, 5-30 parts of nano-silver ion antibacterial powder, 20-50 parts of nano-infrared powder, 5-30 parts of chitin;

[0025] Or, in this step, in order to realize lasting, efficient antibacterial effect, this antibacterial material is the nanoparticle state material that comprises metal salt and negative ion powder, and it is preferably made of the following components ...

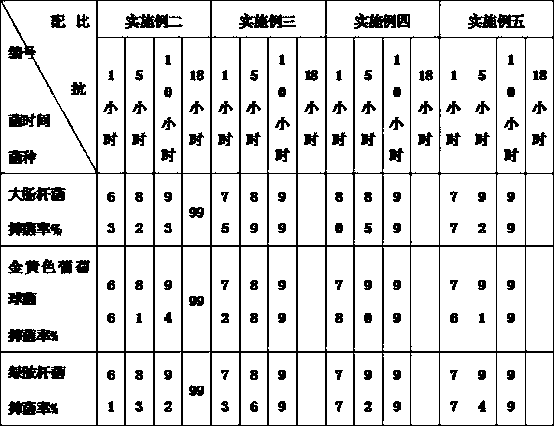

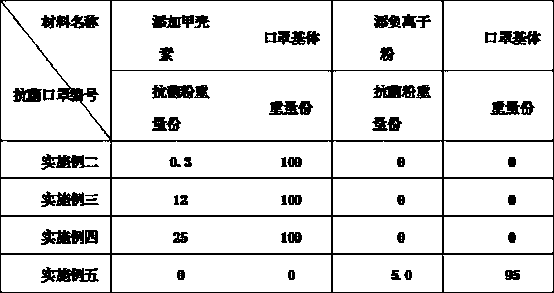

Embodiment 2

[0046] This embodiment provides an antibacterial mask prepared by the method of Example 1, which includes a mask base made of non-woven fabric, and an antibacterial material is also distributed on the mask base.

[0047] Wherein, the mask substrate is a non-woven fabric with a weight component of 100 parts, and the weight component of the antibacterial material is a mixture of 0.3 parts of inorganic nano antibacterial materials and chitin, and the inorganic nano antibacterial materials are selected from nano-oxidized 5 parts of zinc, 5 parts of nano-silver ion antibacterial powder, 20 parts of nano-infrared powder, and 5 parts by weight of chitin.

Embodiment 3

[0049] This embodiment provides an antibacterial mask prepared by the method of Example 1, which includes a mask base made of non-woven fabric, and an antibacterial material is also distributed on the mask base.

[0050] Wherein, the mask matrix is a non-woven fabric with a weight component of 100 parts, and the antibacterial material is a mixture of 12 parts of inorganic nano antibacterial materials and chitin, and the inorganic nano antibacterial materials are selected for use in this embodiment. 5 parts of zinc oxide, 5 parts of nano-silver ion antibacterial powder, 20 parts of nano-infrared powder, and 5 parts of chitin by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com