Fireproof cotton gloves

A technology of fireproof cotton and gloves, applied in gloves, protective clothing, clothing, etc., can solve the problems of inconvenient use, troublesome wearing and taking off, and inability to play a role in heat insulation, etc., to achieve easy use, quick putting on and taking off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

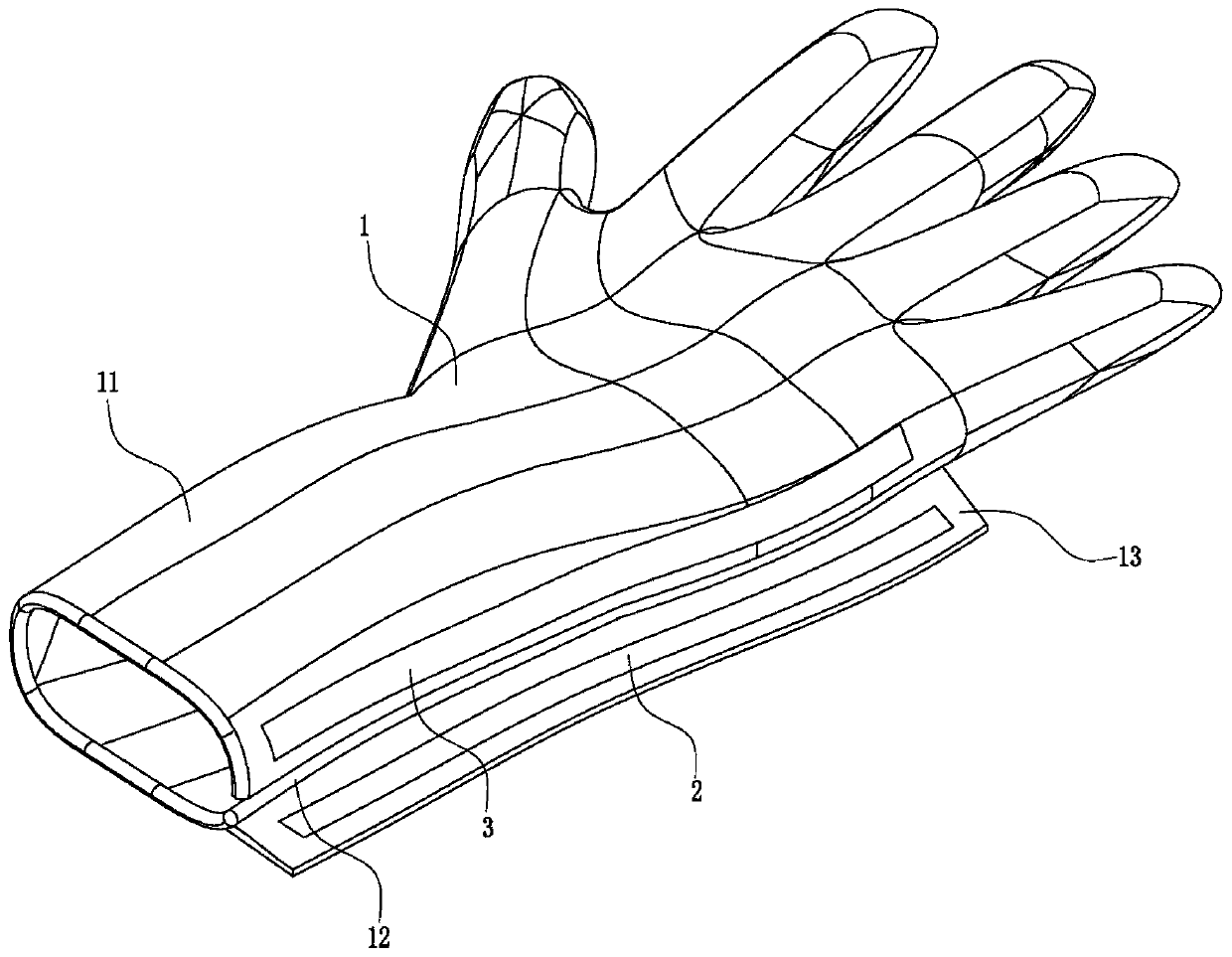

[0008] like figure 1 As shown, a fireproof cotton glove includes a body 1, a male surface of Velcro 2 and a female surface of Velcro 3; There is an opening groove 12, and a flange 13 is formed on one edge of the opening groove 12 outward, and the male surface 2 of the Velcro is fixed on the inner side of the flange 13. Correspondingly, the female surface 3 of the magic fastener is fixed on the body 1 and the extension sleeve 11. Between the lower sides and above the edge of the other side of the opening groove 12, the female surface 3 of the Velcro buckle and the male surface 2 of the Velcro are matched with each other.

[0009] When in use, the edges on both sides of the opening groove 12 are opened outward, and then the hand is inserted into the body 1, and the five fingers are respectively inserted into the five corresponding finger cots on the body 1, while the wrist part is Insert into the extension sleeve 11, then turn up the flange 13 on one side of the opening slot 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com