Transporter

A technology of transporter and friction block, which is applied in the field of transporter, can solve the problems of no consideration of the conveying speed of the transporter, low versatility, and slow decline in the weight of the number of people, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

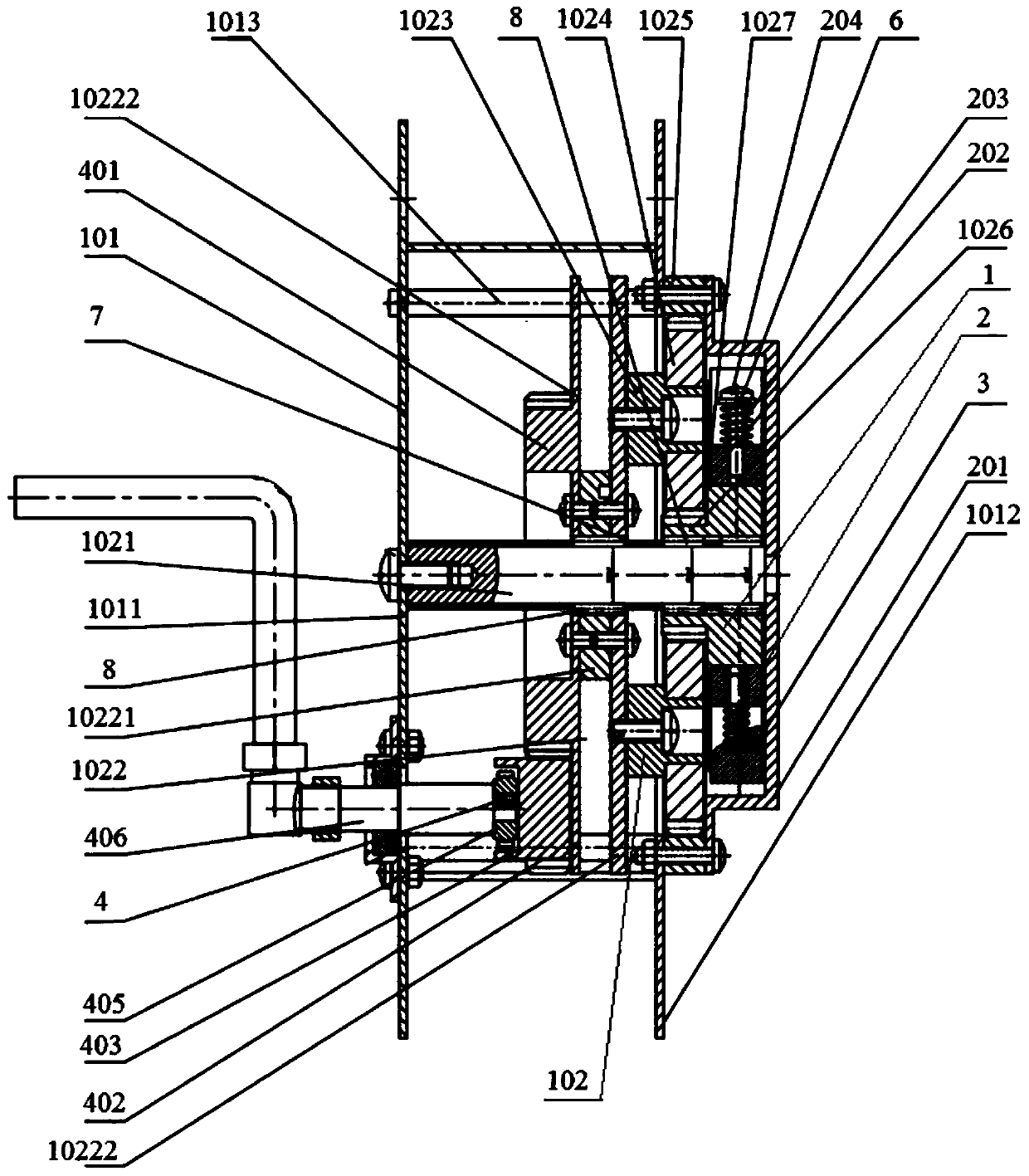

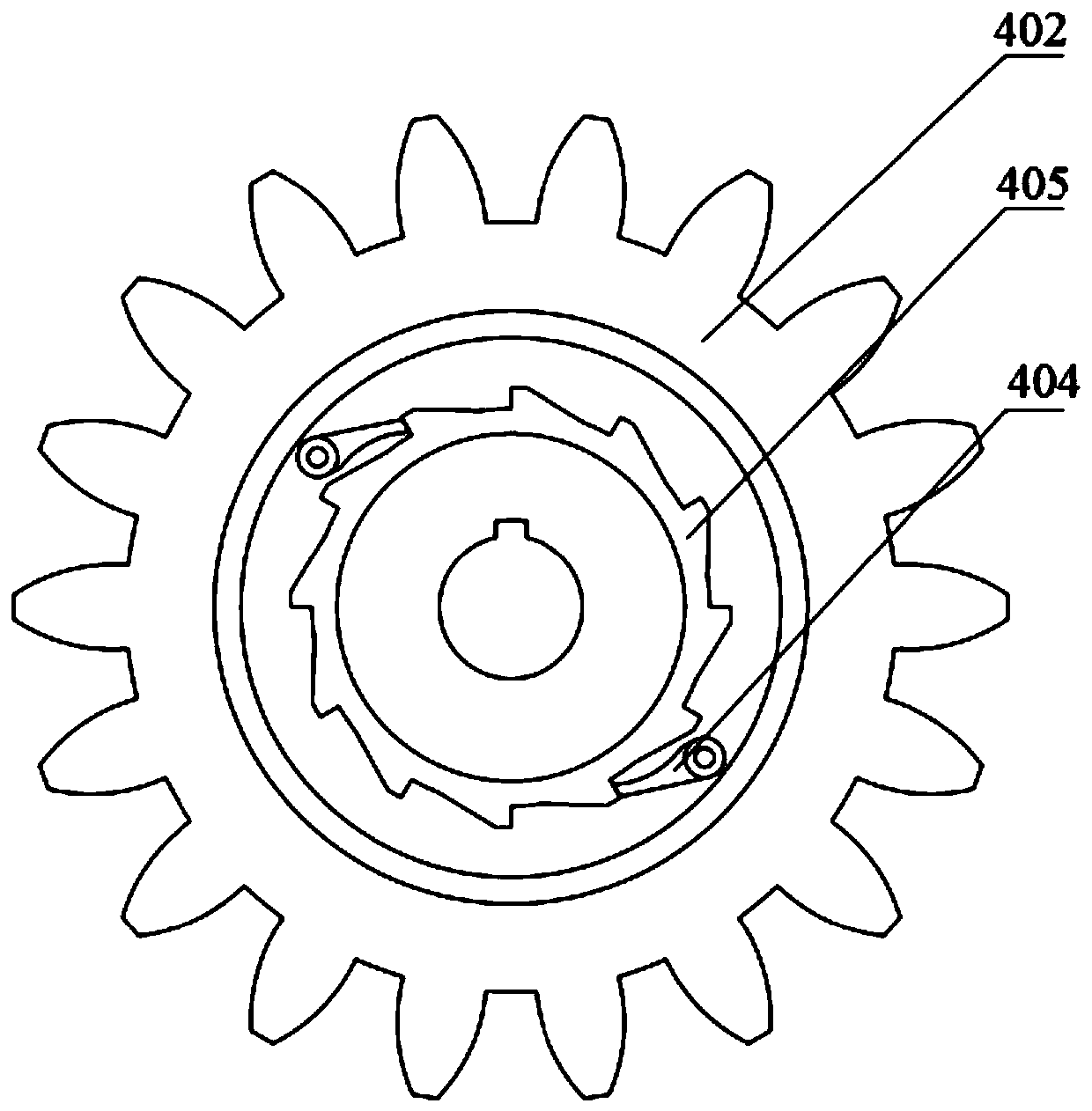

[0074] Such as Figure 1-8 As shown, the present invention discloses a transporter. Wherein, the transporter includes a transmission mechanism 1 and a speed limiting mechanism 2 .

[0075] The transmission mechanism 1 includes a fixed part 101 and a rotating part 102. The fixed part 101 can be two plates connected together, and the rotating part 102 can be rotatably installed between the two plates; it can also be a shell, and the rotating part 102 can be rotatably installed. In the housing, other structures are also possible. The safety rope is wound on the rotating part 102 and can be retracted along with the rotating part 102 . The safety rope 10 can be a steel wire rope, or a hemp rope, or can be made of other materials, as long as the safety rope 10 that can realize material transportation is satisfied, all belong to the protection scope of the present invention.

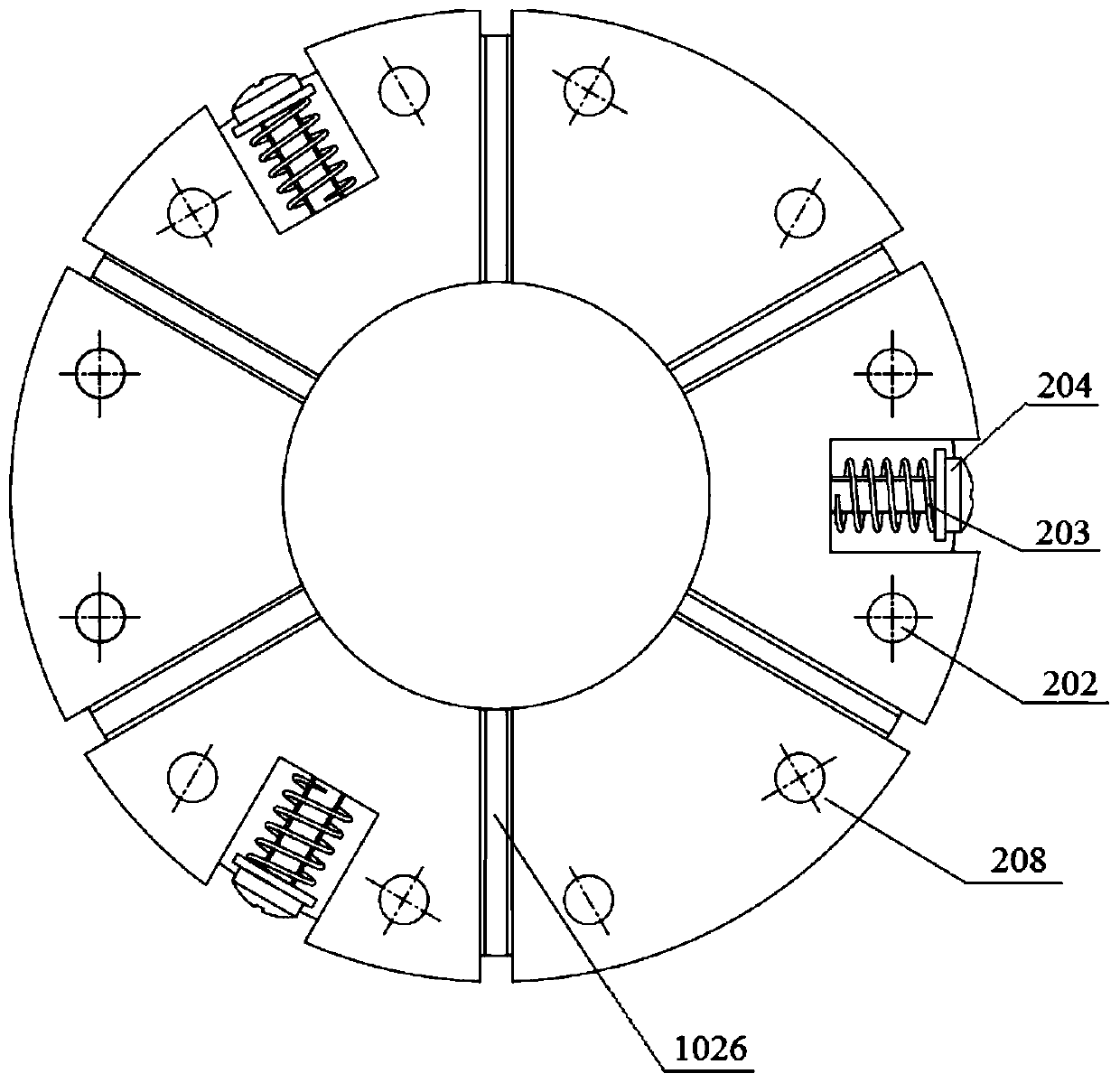

[0076] The speed limiting mechanism 2 includes a friction disc 201 , a first friction block 202 , a first...

Embodiment 2

[0084] Such as Figure 5-8 As shown, in the second embodiment provided by the present invention, the transporter in this embodiment is similar in structure to the transporter in the first embodiment, and the similarities will not be repeated, and only the differences will be introduced.

[0085] In this embodiment, the present invention specifically discloses that the speed limiting mechanism 2 further includes a second friction block 205 , a second screw 206 and a second spring 207 .

[0086] The second friction block 205 is provided with a second mounting groove and a second optical hole in sequence along the direction from its top to the bottom, the top of the second optical hole is connected to the bottom of the second mounting groove, and the second screw 206 is sleeved on the In the second spring 207, the second spring 207 is pressed in the second installation groove, and the screw rod of the second screw 206 passes through the second light hole and is screwed on the rot...

Embodiment 3

[0111] Such as Figure 1-4 As shown, in the third embodiment provided by the present invention, the transporter in this embodiment is similar in structure to the transporter in the second embodiment, and the similarities will not be repeated, and only the differences will be introduced.

[0112] In this embodiment, the present invention discloses that the speed limiting mechanism 2 further includes a fourth friction block 208 .

[0113] The fourth friction block 208 is fixed on the rotating part 102, and the fourth friction block 208 abuts against the inner wall of the friction disc 201, and when the rotating part 102 rotates, the fourth friction block 208 can generate friction torque with the friction disc 201, that is to say , the fourth friction block 208 is always in contact with the friction disc 201 , and generates friction torque with the inner wall of the friction disc 201 as the rotating part 102 rotates. The fourth friction block and the rotating part 102 may be wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com