A kind of preparation method of modified dialdehyde starch for adsorbing lead ions

A technology of dialdehyde starch and lead ions, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem that the modified dialdehyde starch lead ion has no ideal effect, and achieve easy industrial production , good adsorption performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

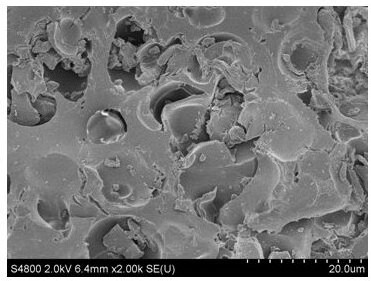

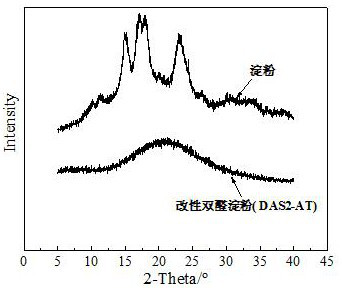

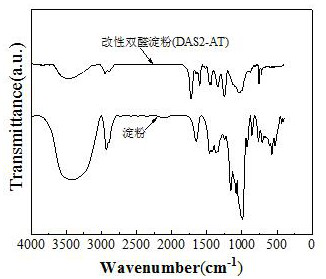

Image

Examples

Embodiment 1

[0023] (1) Preparation of Dialdehyde Starch (DAS)

[0024] Weigh 4g of potato starch, add 5mL of deionized water and stir constantly to form a suspension, place it in a dark box, then slowly add 80mL of sodium periodate with a concentration of 0.5mol / L dropwise, and then adjust the pH value with 0.05mol / L of dilute sulfuric acid for 3. Under the condition of 30° C., react in the dark for 1 hour, filter and wash with deionized water until neutral, and dry in an oven at 50° C. to obtain dialdehyde starch (DAS).

[0025] (2) Preparation of 5-aminoisophthalate-modified dialdehyde starch (DASD5-A)

[0026] 3g of methyl 5-aminoisophthalate was dissolved in a three-necked flask with 50mL of organic solution, and 4g of DAS obtained in step (1) was added to the above-mentioned three-necked flask, and 0.2mL of glacial acetic acid was added dropwise. After reacting at 30° C. for 4 hours under the protection of the protection, it was washed with absolute ethanol and dried overnight at 5...

Embodiment 2

[0032] (1) Preparation of Dialdehyde Starch (DAS)

[0033] Weigh 6g of corn starch, add 10mL of deionized water and stir continuously to form a suspension, place it in a dark box, then slowly add 100mL of sodium periodate with a concentration of 1.0mol / L dropwise, and then adjust the pH value with 0.1mol / L of dilute sulfuric acid for 4. Under the condition of 50° C., react in the dark for 4 hours, filter and wash with deionized water until neutral, and dry in an oven at 60° C. to obtain dialdehyde starch (DAS).

[0034] (2) Preparation of 5-aminoisophthalate-modified dialdehyde starch (DASD5-A)

[0035] 5g of methyl 5-aminoisophthalate was dissolved in a three-necked flask with 80mL of organic solution, and 6g of DAS obtained in step (1) was added to the above-mentioned three-necked flask, and 0.3mL of glacial acetic acid was added dropwise. After reacting at 60° C. for 8 hours under the protection of gas, it was washed with anhydrous methanol and dried overnight at 60° C. t...

Embodiment 3

[0041] (1) Preparation of Dialdehyde Starch (DAS)

[0042] Weigh 8g of tapioca starch, add 20mL of deionized water and stir continuously to form a suspension, place it in a dark box, then slowly add 120mL of sodium periodate with a concentration of 1.2mol / L dropwise, and then adjust the pH value with 0.15mol / L of dilute sulfuric acid for 4. Under the condition of 60°C, react in the dark for 6 hours, filter and wash with deionized water until neutral, place in an oven and dry at 70°C to obtain dialdehyde starch (DAS).

[0043] (2) Preparation of 5-aminoisophthalate-modified dialdehyde starch (DASD5-A)

[0044]The 5-aminoisophthalic acid methyl ester of 7g is dissolved in the three-necked flask that 100mL organic solution is housed, the DAS that 8g step (1) obtains is added in the above-mentioned three-necked flask again, 0.5mL glacial acetic acid is added dropwise, under argon After reacting at 70° C. for 12 hours under the protection of gas, it was washed with anhydrous DMSO...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap