Workpiece paint spraying protection equipment adopting gliding flow guide principle

A technology for protecting equipment and workpieces, applied in spray booths, spraying devices, etc., can solve problems such as threats to life and health, achieve the effects of avoiding threats, preventing external diffusion from contacting workers, and improving absorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

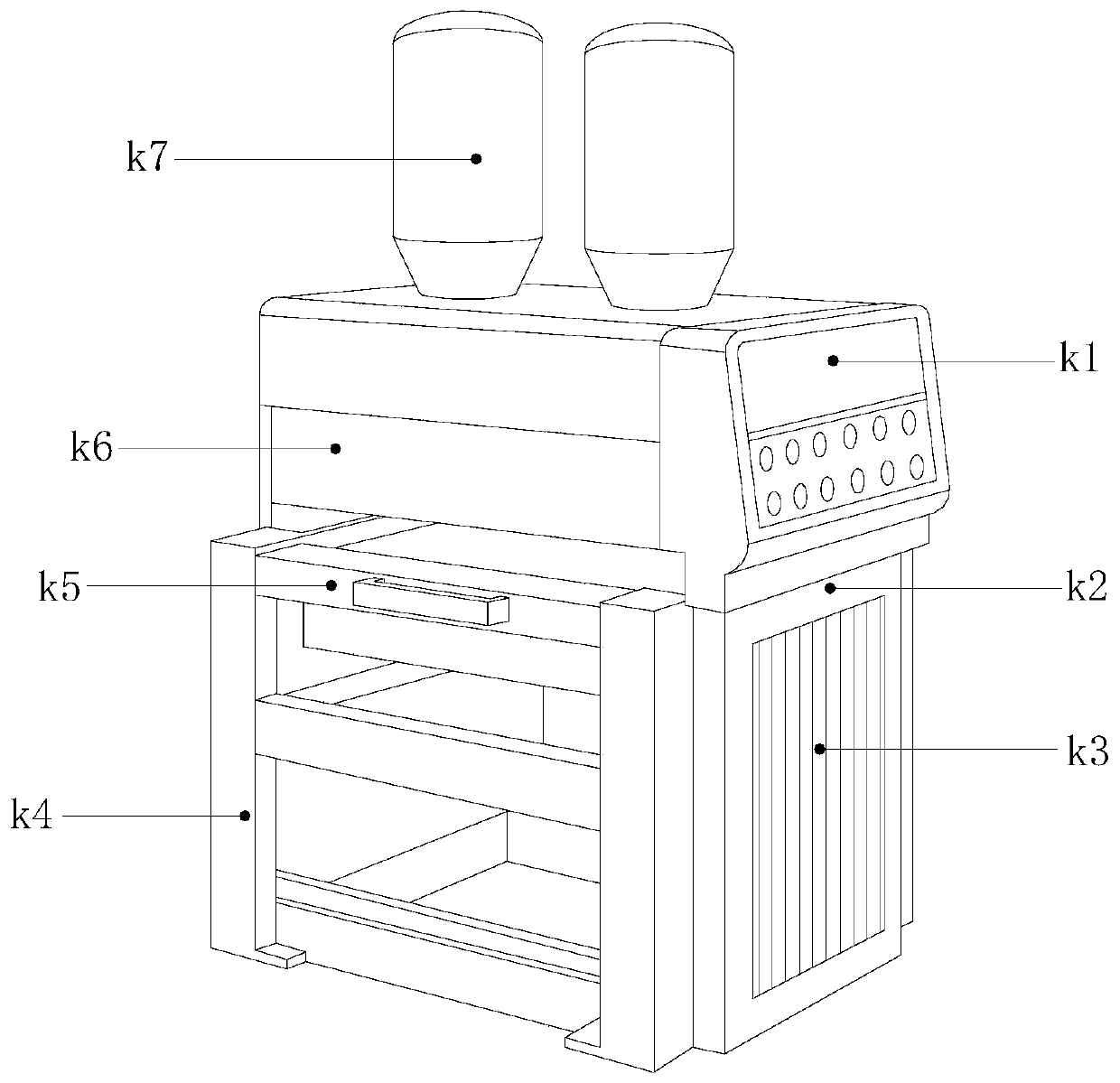

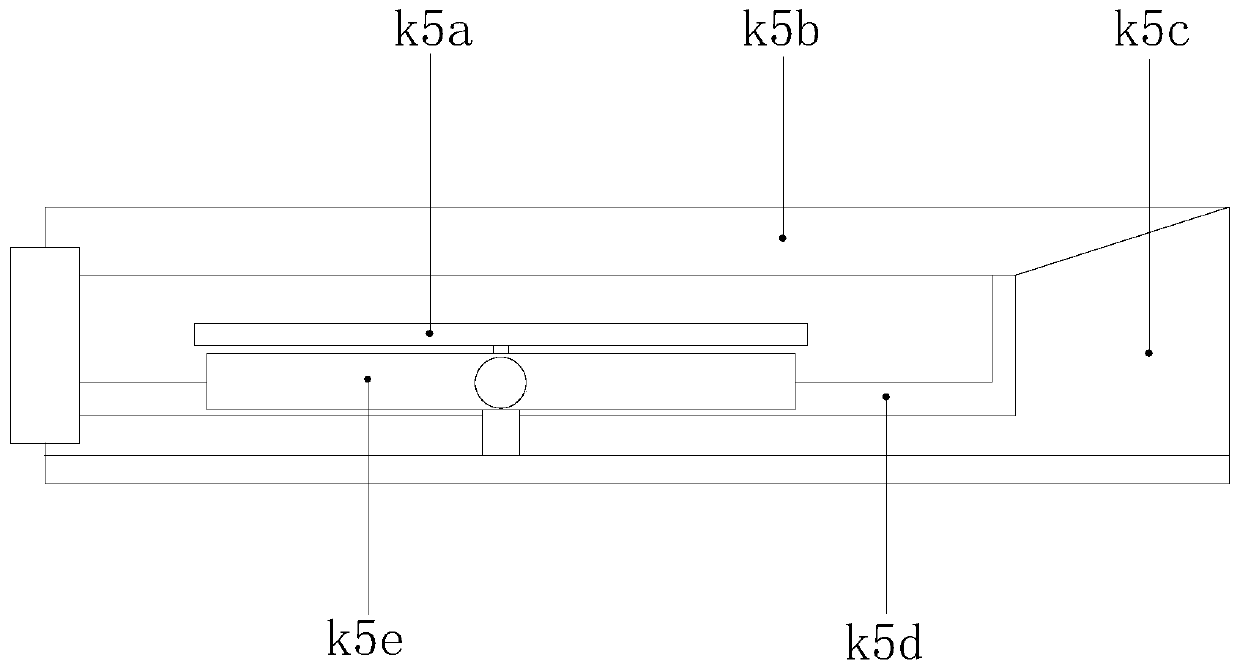

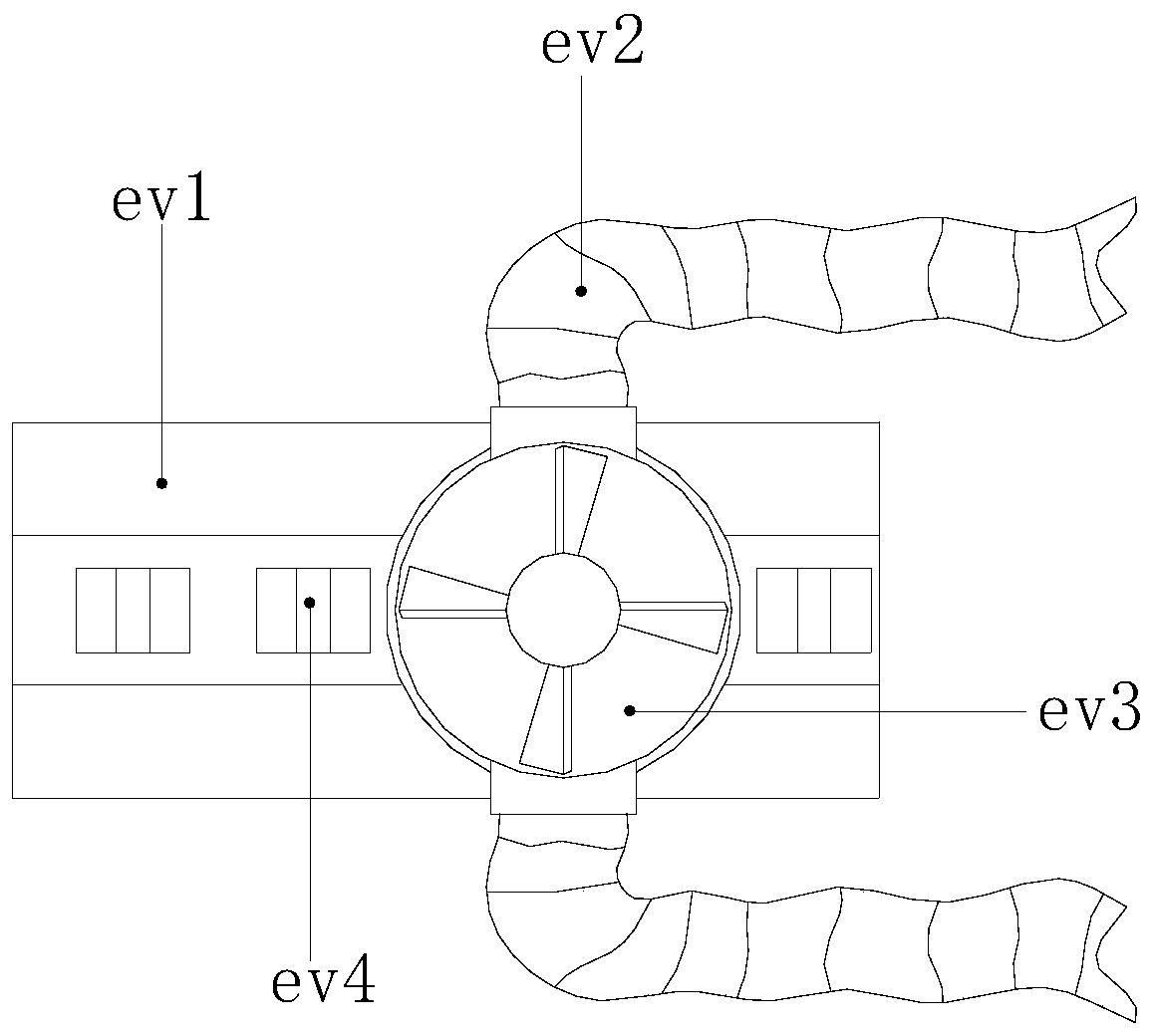

[0030] see Figure 1-Figure 7 , the present invention provides a kind of workpiece paint protection equipment that adopts the principle of sliding to drainage, and its structure includes controller k1, main machine k2, heat dissipation groove k3, fixed frame k4, support mechanism k5, paint spraying chamber k6, paint tank k7, described The host machine k2 has a rectangular structure, and is installed on the right end of the fixed frame k4 by embedding. The top of the fixed frame k4 is provided with a paint spraying chamber k6, and the left and right ends of the support mechanism k5 are fitted with the upper end of the fixed frame k4. Groove k3 is set in the middle of the host machine k2, and is an integrated structure. There are two paint tanks k7, which are installed on both ends of the top of the paint spraying chamber k6 by buckling, and the bottom of the paint spraying chamber k6 is connected to the support mechanism k5 connected, the bottom of the controller k1 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com