Full-automatic product detection machine

A product inspection machine, fully automatic technology, applied in sorting and other directions, can solve the problems of inability to detect waste products, defects in the appearance of cigarette boxes, low detection efficiency, etc., to improve detection efficiency and detection accuracy, and improve the rejection rate of defective products. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

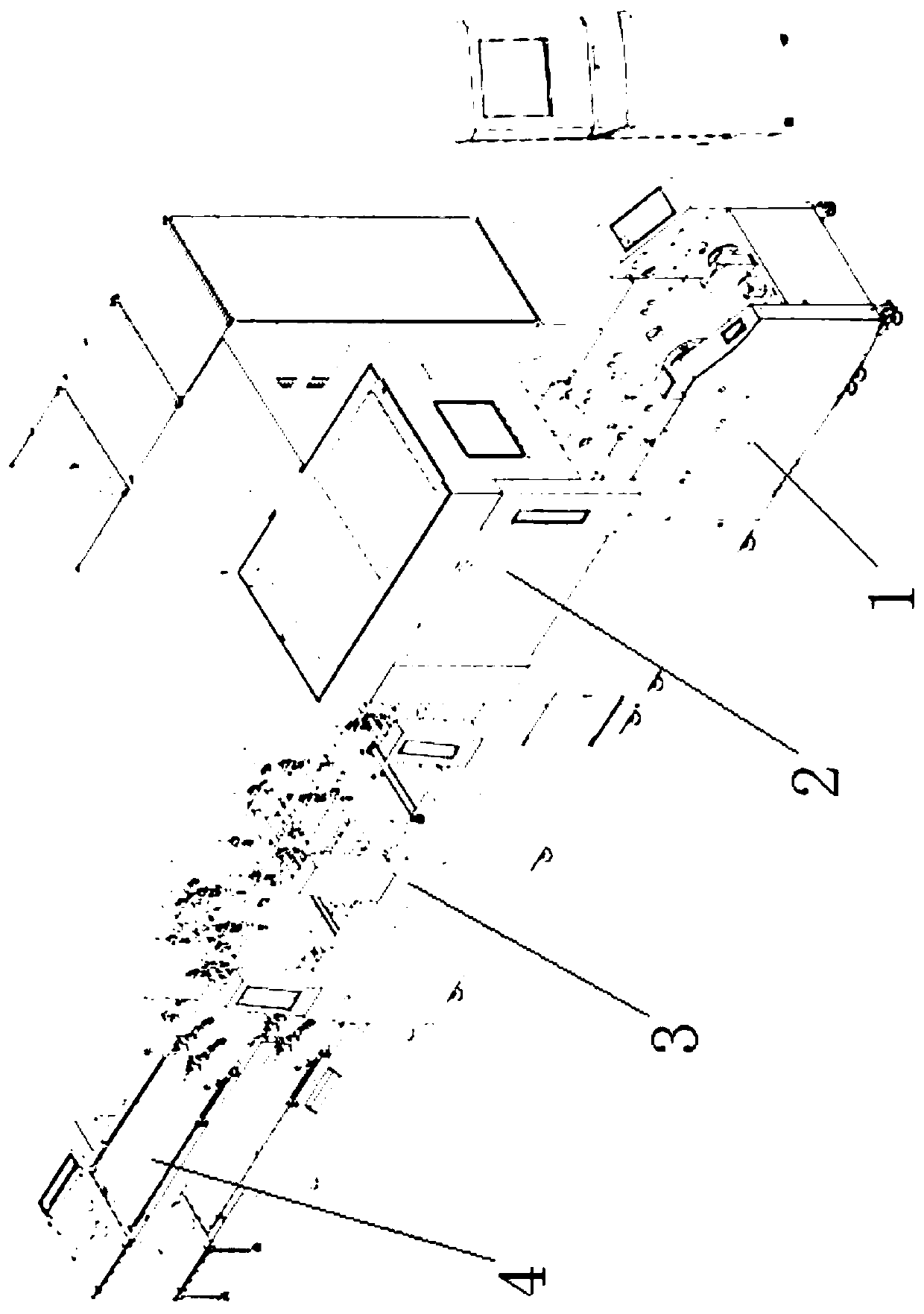

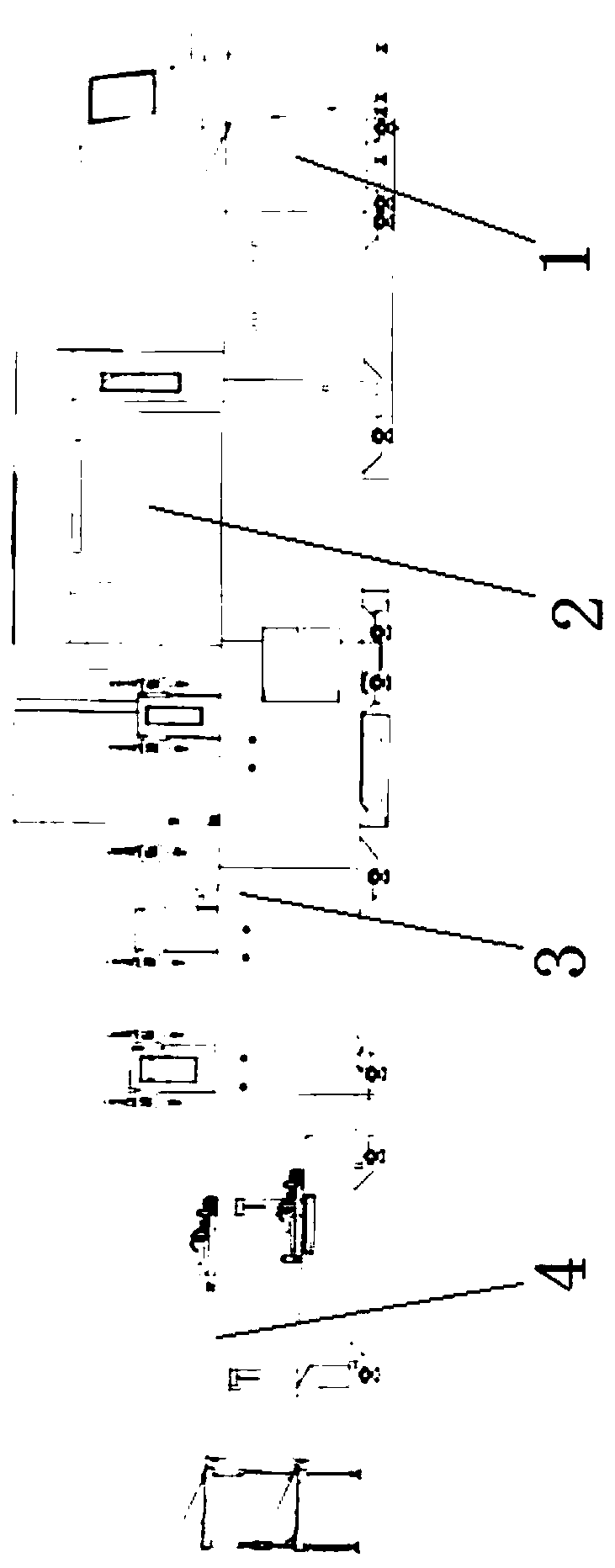

[0026] See Figure 1~6 , The present invention relates to a fully automatic inspection machine, which includes a paper feeding mechanism 1, a detection mechanism 2, a rejection mechanism 3 and a collection mechanism 4; the paper feeding mechanism 1, the detection mechanism 2, the rejection mechanism 3 and the collection mechanism 4 are conveyed along The conveying direction of the belt is set in sequence;

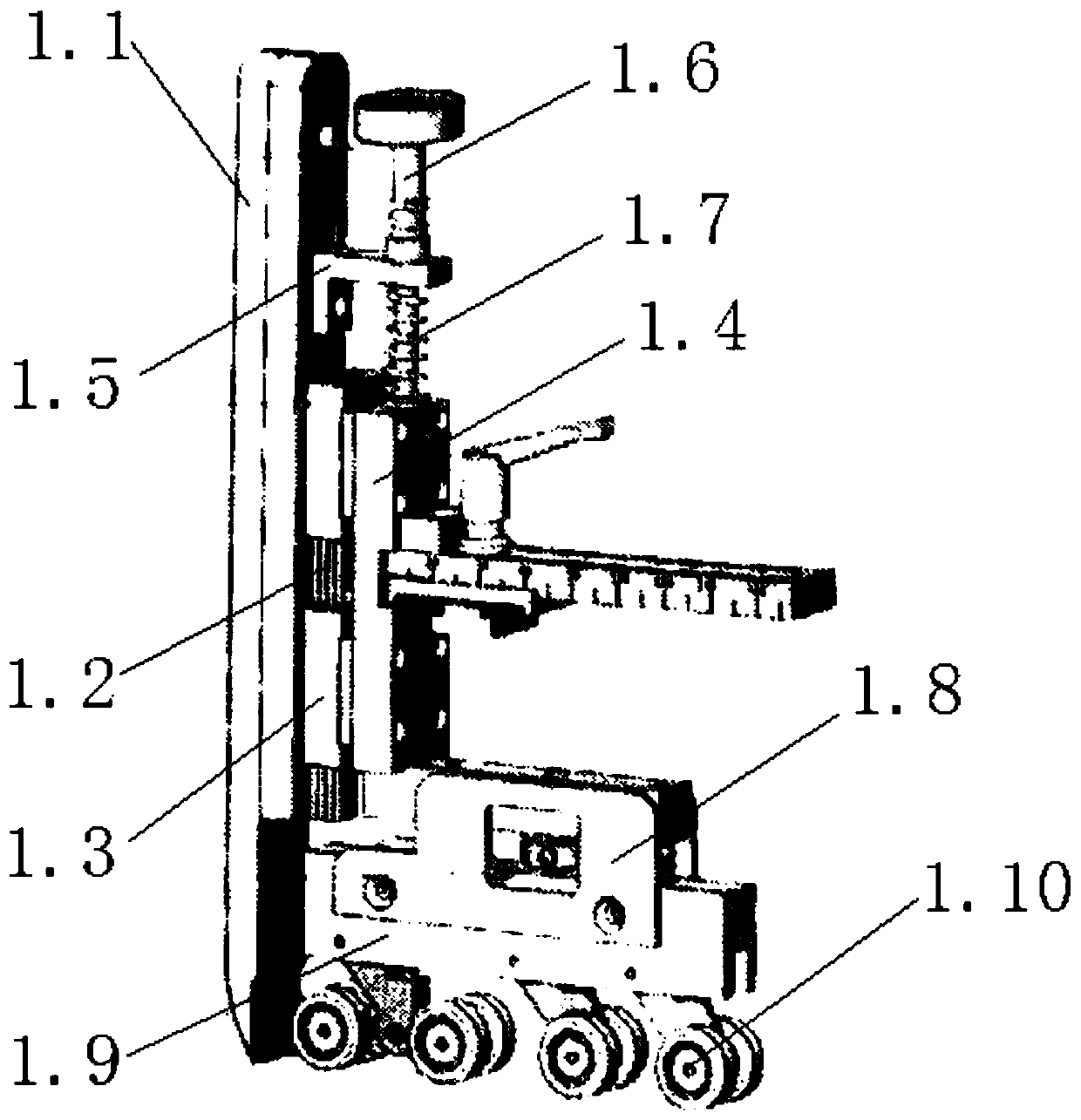

[0027] The paper feeding mechanism 1 includes a paper feeding knife 1.1, a linear slide rail 1.2, a sliding block 1.3, an adjusting seat 1.4, a connecting bracket 1.5, an adjusting bolt 1.6, and a spring 1.7; the paper feeding knife 1.1 is set vertically, and the paper feeding knife 1.1 A linear slide rail 1.2 is provided along the length of the center of the right side of the slide block; the slider 1.3 is slidably clamped on the linear slide rail 1.2; the right side of the slide block 1.3 is fixedly installed with an adjusting seat 1.4, the adjustment The seat 1.4 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com