Biomass fuel impurity separating method and device

A biomass fuel and impurity technology, applied in the direction of solid separation, chemical instruments and methods, classification, etc., can solve the problems of damage, damage to the hood, easy wrapping and mixing of crushed stones, soil clods, etc., to achieve good separation effect and eliminate high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

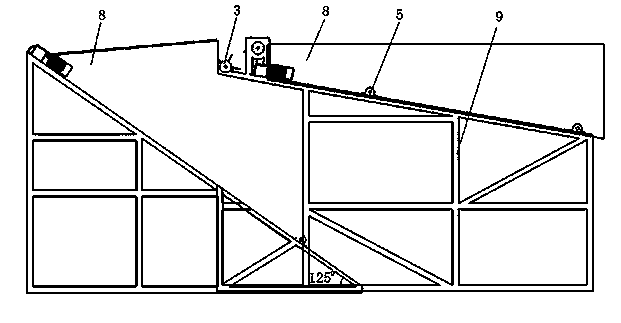

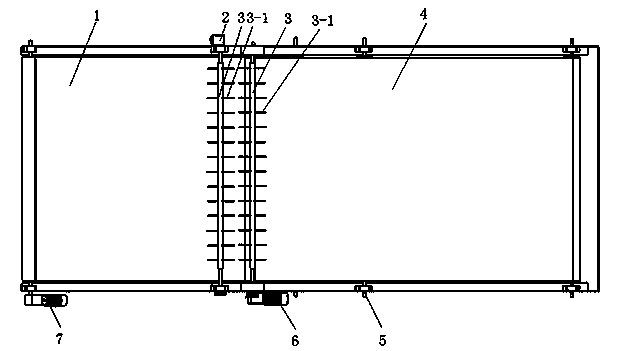

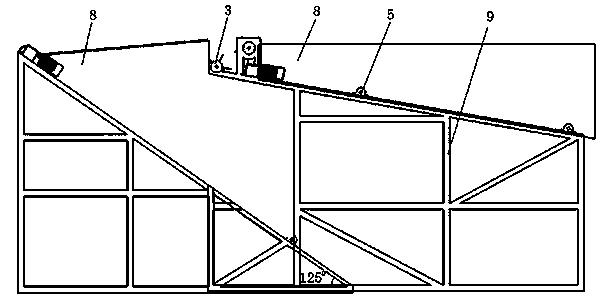

[0021] refer to figure 1 , the invention discloses a method for separating impurities from biomass fuel, comprising the following steps:

[0022] Breaking up step: place the unseparated biomass fuel on the first-stage conveyor belt, and set a break-up roller at the discharge end of the first-stage conveyor belt to remove the stones, soil, etc. wrapped by the biomass fuel flocculent Break up impurities such as lumps;

[0023] Separation step: Install a second-stage conveyor belt inclined and running upwards below the discharge end of the first-stage conveyor belt to receive the dispersed biomass fuel. The strong biomass fuel is discharged along with the belt, and the impurities such as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com