Cutting production line intelligently used for cement foamed heat preservation boards

A technology of cement foaming and cutting wire, applied in the field of cutting wire, can solve the problems of low degree of intelligence, low production efficiency, low efficiency, etc., and achieve the effect of realizing electric control and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

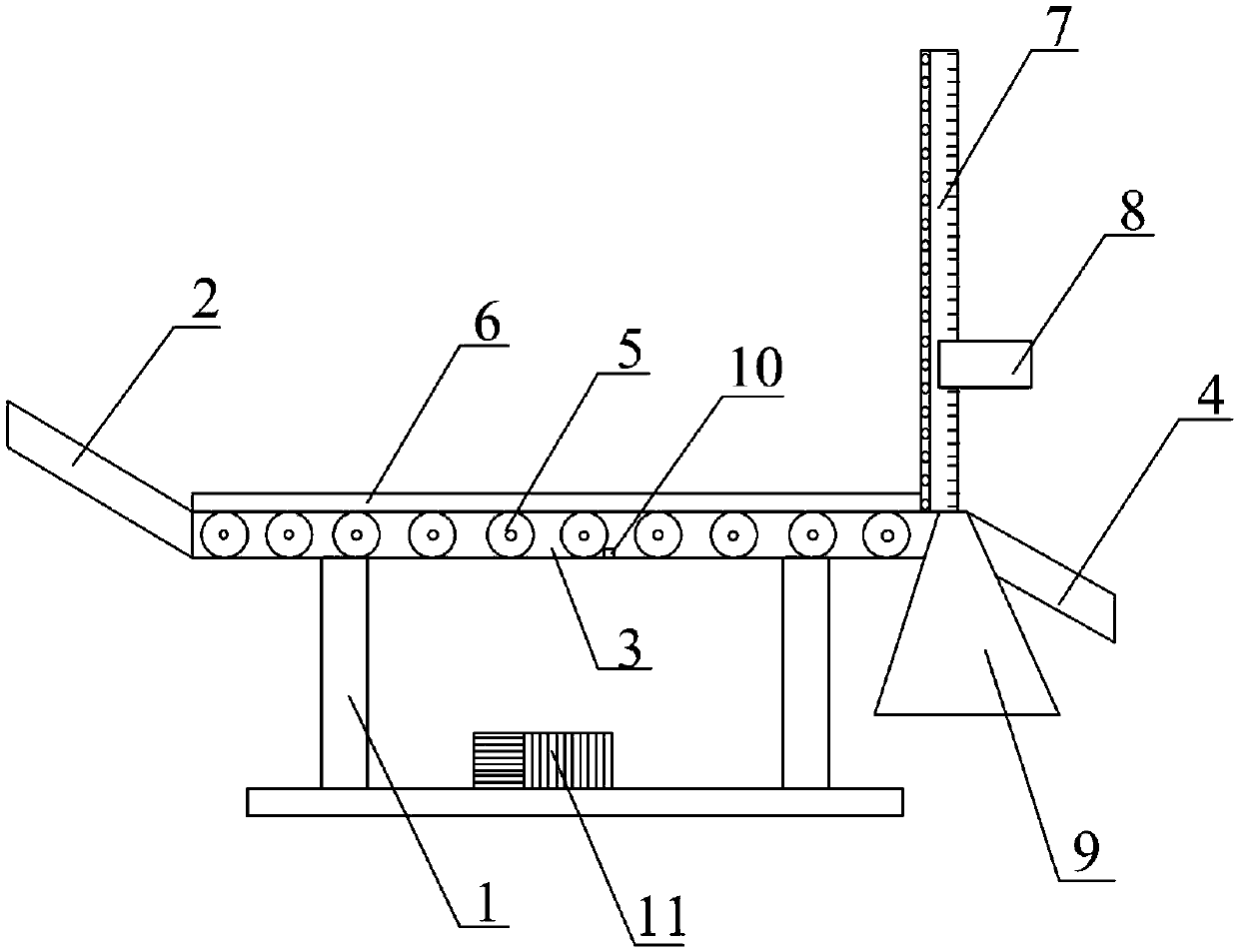

[0024] as attached figure 1 to attach image 3 shown

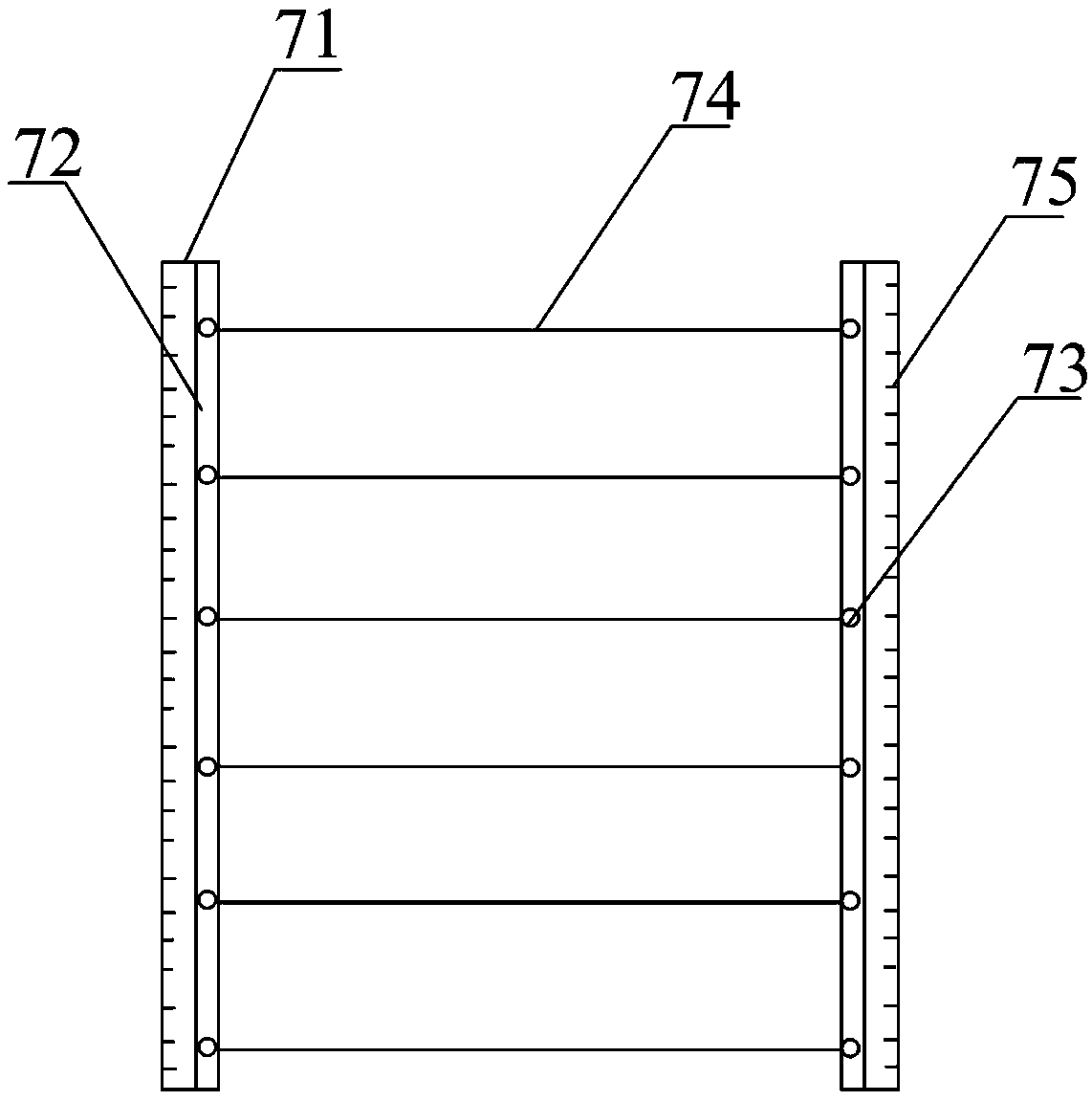

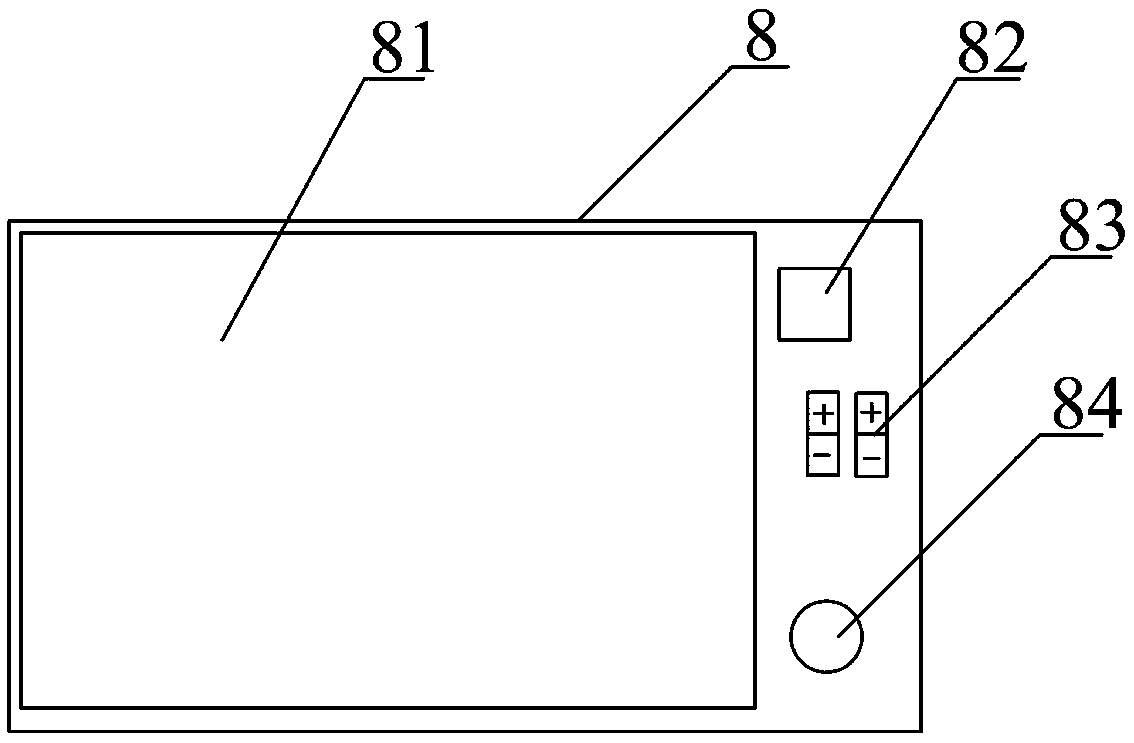

[0025] The invention provides an intelligent cutting line for cement foam insulation board, which includes a bracket 1, a feed port 2, a cutting table 3, a discharge port 4, a rotating roller 5, a side baffle 6, a cutting device 7, and a display The control device 8, the waste collection tank 9 and the motor 11, the cutting table 3 is erected on the upper part of the support 1 and connected to the feed port 2 and the discharge port 4; the cutting table 3 side is equipped with a rotating roller 5 ; Both sides of the upper part of the cutting table 3 are provided with side baffles 6; the cutting device 7 is arranged at the junction of the cutting table 3 and the discharge port 4; the display control device 8 is installed on the cutting device 7 The waste collection tank 9 is arranged at the bottom of the cutting device 7; the motor 11 is arranged at the bottom of the support 1; the cutting device 7 includes a vertical rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com