Composite forming method of multifunctional integrated composite material

A composite material and composite forming technology, used in additive processing, manufacturing tools, processing data acquisition/processing, etc., can solve problems such as complex integral forming, shorten the manufacturing cycle, have strong designability, and ensure integrity and comprehensiveness. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

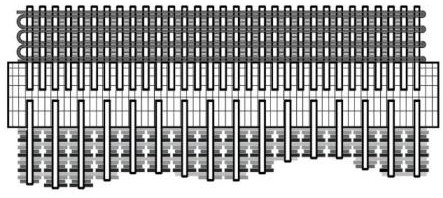

[0032] like Figure 4 As shown in the schematic diagram of the composite material curved surface member, using a composite forming method of a multifunctional integrated composite material of the present invention, the weaving forming steps are as follows:

[0033] ① Use CAD and other software to establish the 3D CAD model of the surface component, and divide the 3D CAD model into functional area 1, functional area 2 and transition area;

[0034] ②Functional area 1 is the basic frame and main part of the component, which is formed by the flexible guiding three-dimensional weaving forming process;

[0035] ③Functional area 2 is mainly a few reinforcing ribs on the outer layer of the component, using continuous fiber 3D printing technology;

[0036] ④ According to the performance requirements of functional area 1 and functional area 2, establish the 3D CAD model of transition area 1 between functional area 1 and functional area 2;

[0037] ⑤Using the flexible-guided three-dime...

Embodiment 2

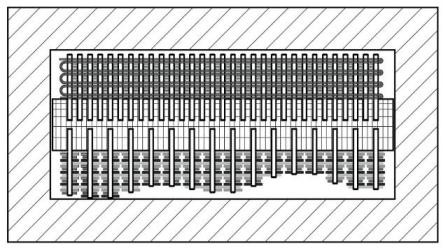

[0041] like Figure 5 As shown in the schematic diagram of the multi-functional integrated composite material component of the complex structure, using a composite forming method of the multi-functional integrated composite material of the present invention, the weaving and forming steps are as follows:

[0042] ① Establishing a three-dimensional CAD model of the complex structural composite material component, and partitioning the three-dimensional CAD model to obtain functional area 1, functional area 2, functional area 3, transition area 1, and transition area 2;

[0043] ②Using 3D printing technology to manufacture transition zone 1 and transition zone 2 of short fiber reinforced composite materials, the density of short fibers in transition zone 1 is distributed in a gradient along the radial direction, and the short fibers in transition zone 2 are evenly distributed;

[0044] ③ Arrange the guide arrays of functional area 1 and functional area 2 through the guide template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com