Pipeline construction method of excavating groove and burying pipe

A construction method and pipeline technology, which is applied in sewer pipeline systems, waterway systems, water supply devices, etc., can solve problems such as accelerated pile driving speed and poor protection measures for pipe groove side walls, so as to reduce friction and improve pile pulling efficiency , The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

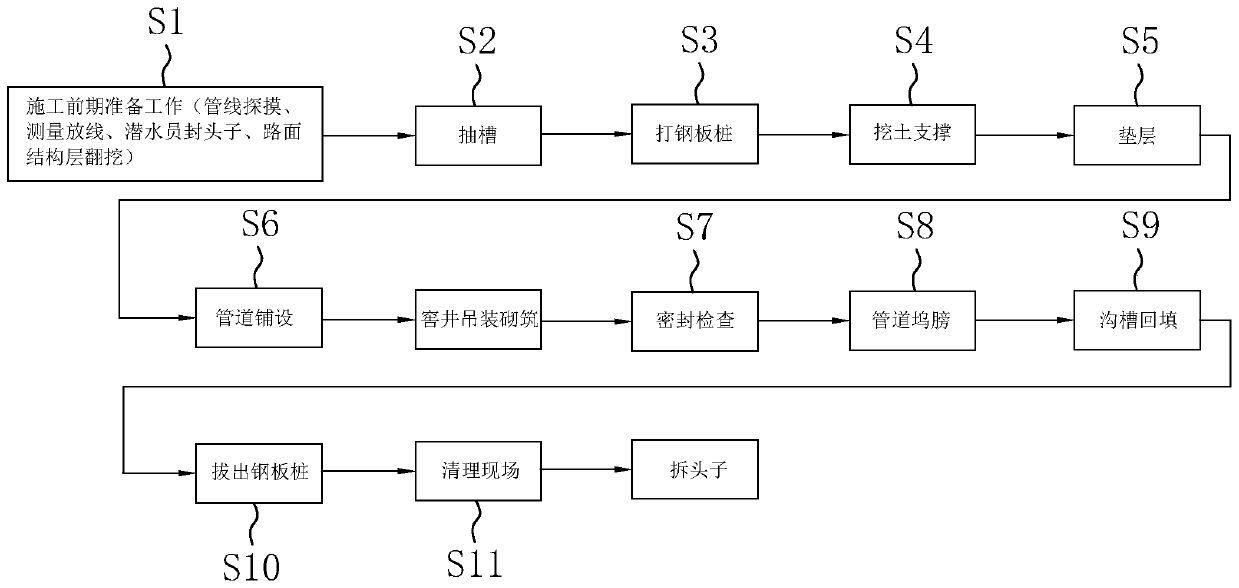

[0054] A construction method for pipelines using excavated trenches and buried pipes, combined with figure 1 It can be seen that the following construction method steps are included:

[0055] S1: Pre-construction preparations. Pre-preparation is sufficient and reasonable. After entering the site, carefully check the distribution of underground pipelines in the community and the situation of old sewage pipelines. Combine the design and construction drawings to stake out the new pipe positions, and dig sample holes before trench excavation. , and indicate on the general construction plan the underground pipelines that affect the construction and are affected by the construction, adjust the pipe positions of the affected pipelines in time, or block the old pipe positions du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com