A kind of construction method of inverted arch filling integral pouring

A technology of integral pouring and construction method, applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve problems such as line deformation, reduce investment, improve early strength, and resist repeated impact and vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

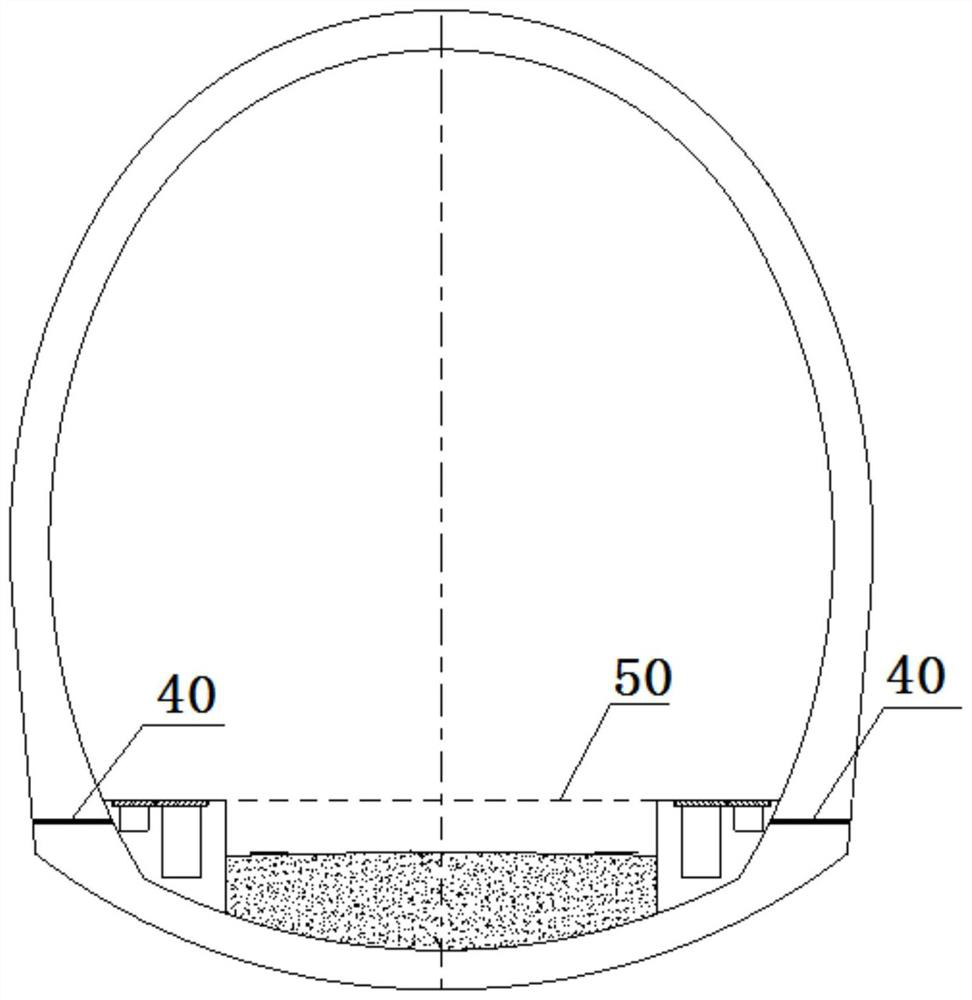

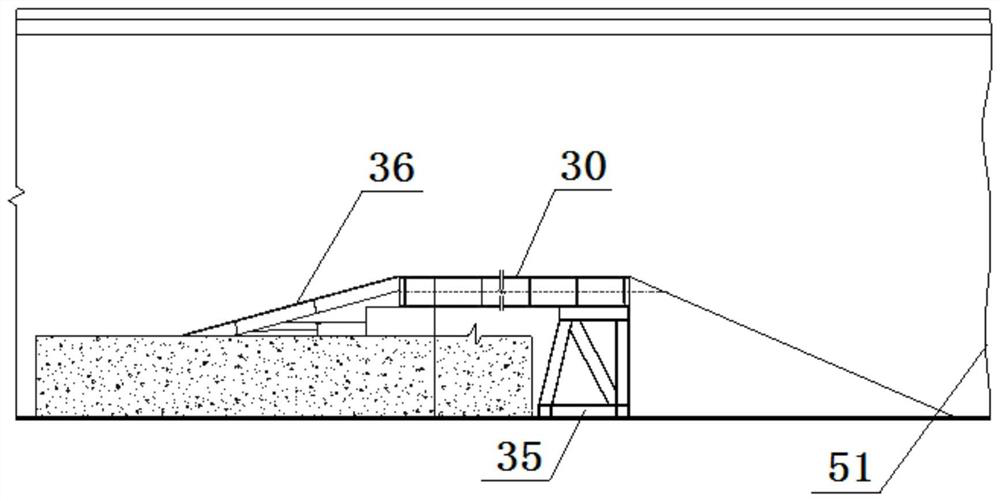

[0036] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, this specific embodiment adopts the following technical scheme: after the tunnel invert 52 is excavated and supported, the invert 52 and the filling part 56 are closed to the design position at one time by using the filling formwork and the trestle 30 according to the design size, realizing One-time support process, and then carry out one-time pouring of concrete to the position filled with concrete, that is, the invert 52 and its filling part 56, that is, to realize integral pouring, and cycle operations in sequence until the entire construction work of the tunnel invert 52 is completed. . The operation difficulty is reduced, the concrete filling process is simple and the strength can be guaranteed, which meets the relevant design requirements.

specific Embodiment approach 2

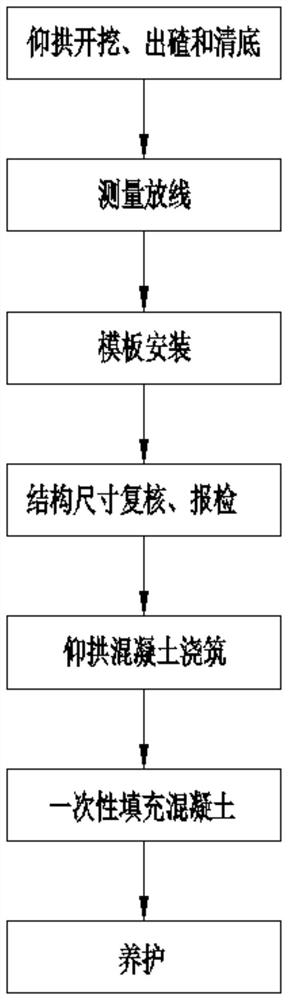

[0037] Embodiment 2: This embodiment is a further limitation of Embodiment 1. The construction method includes the following steps:

[0038] Excavation, ballasting and bottom cleaning of the inverted arch 52: excavate the inverted arch 52 according to the cross-sectional drawing of the design drawing, and clean the inverted arch 52 base after the excavation of the inverted arch 52 to ensure that the inverted arch 52 base has no virtual slag;

[0039] Formwork installation: perform the lining operation of the inverted arch 52 on the base of the inverted arch 52 after slag removal. After the inverted arch 52 lining is completed, select the trestle 30 and one or two sets of inverted arches to fill the integral pouring formwork according to the tunnel type. Complete the installation of the end shaped formwork for the inverted arch and the installation of the integral arc formwork 1 for the side wall to form the integral pouring formwork for the inverted arch filling; the integral pou...

specific Embodiment approach 3

[0043] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. After the formwork is installed, it is necessary to review the structural size of the inverted arch 52 and apply for inspection. After the size compounding and inspection meet the design requirements, Concrete pouring is performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com