Electronic mechanical hydraulic wire control brake

A brake-by-wire and electromechanical technology, applied in the direction of brakes, brake types, axial brakes, etc., can solve the problems of large size, complex structure of brakes, and variable efficiency of brake actuators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

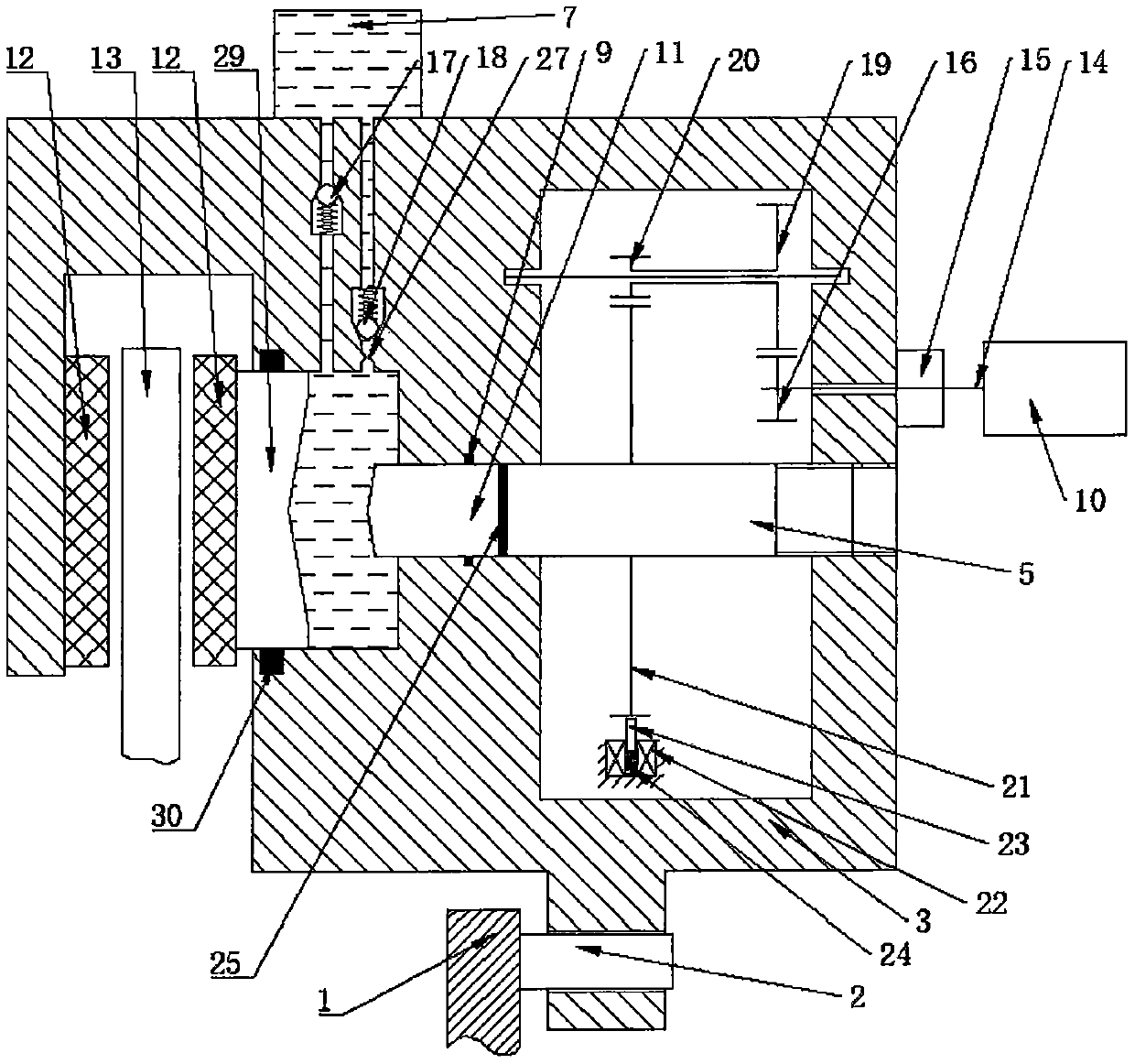

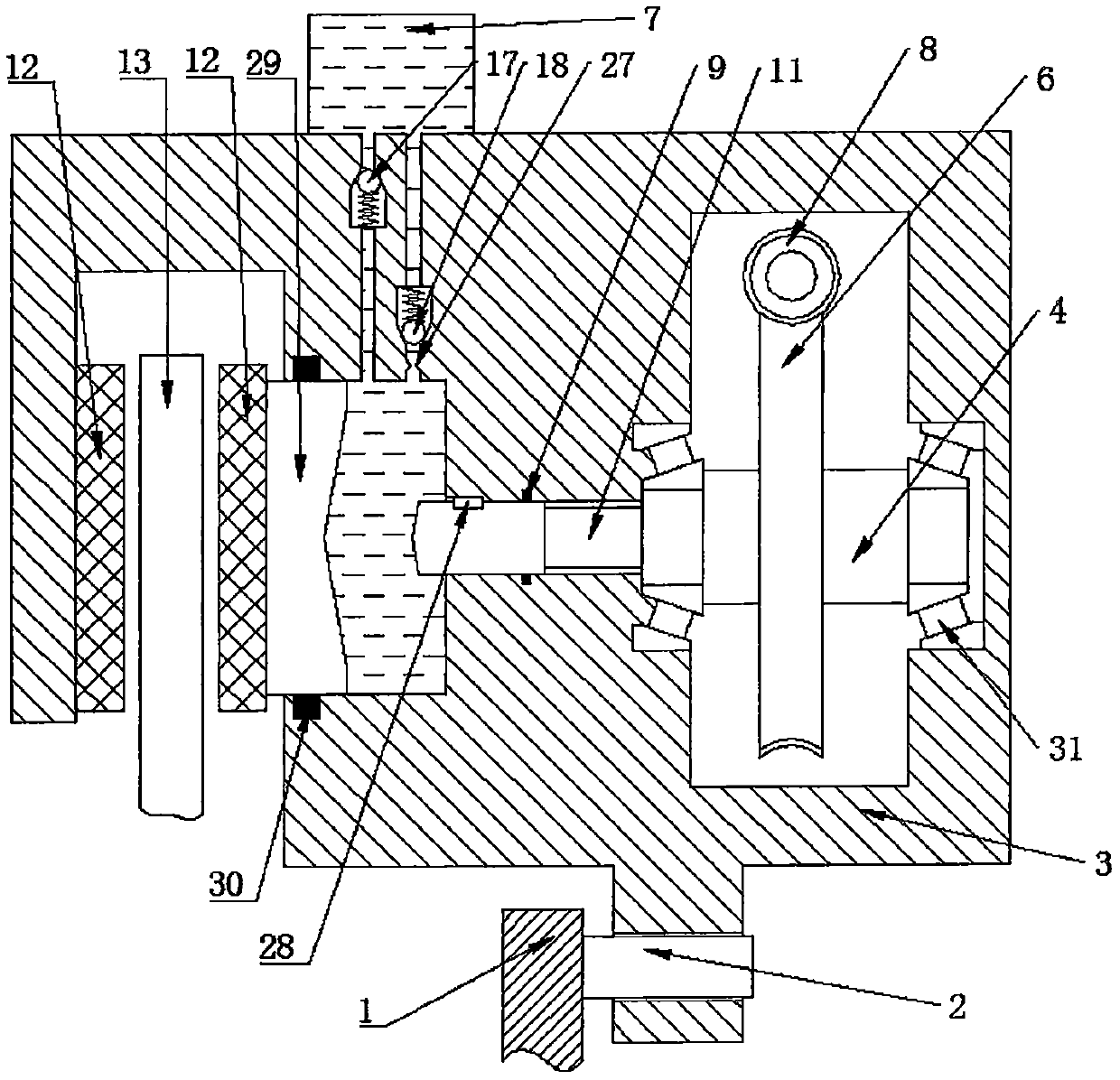

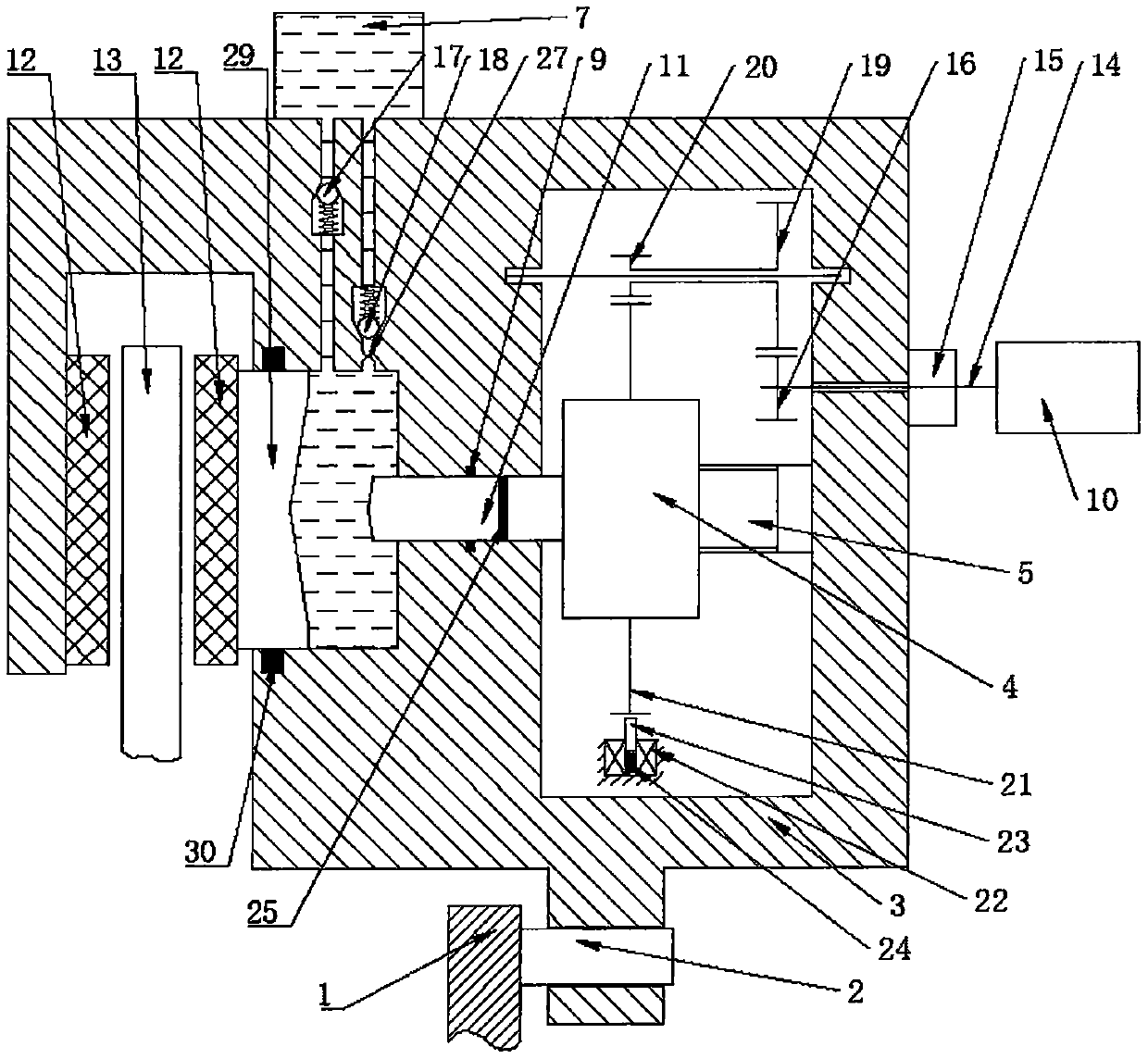

[0025] Reference attached figure 1 , an embodiment of the present invention will be described in detail.

[0026] Such as figure 1 As shown, an electromechanical hydraulic brake by wire includes a brake caliper body (3) that can move on a guide pin (2), and the guide pin (2) is fixed on a brake caliper bracket (1). There are brake discs (13) in the jaws of the brake caliper body (3), and friction discs (12) are arranged on both sides of the brake disc (13), one is contained on the brake caliper body (3), and the other is contained in the large On the piston (29), the large piston (29) is installed on the brake caliper body (3) through the large sealing ring (30). Relatively installed, the small piston (11) is installed in the brake caliper body (3) through a small sealing ring (9), and can move along its axis, and the other end cooperates with the screw (5) of the screw mechanism through a plane thrust bearing (25) , the other end of the screw rod (5) is threaded, which mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com