Semi-automatic gun adjustment precision detection system and method based on bluetooth wireless data transmission

A wireless data transmission, semi-automatic technology, used in weapons testing, offensive equipment, weapon accessories, etc., can solve problems such as reducing use efficiency, occupation, and unfavorable on-site operations, reducing cables, improving detection accuracy, and speeding up measurement speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

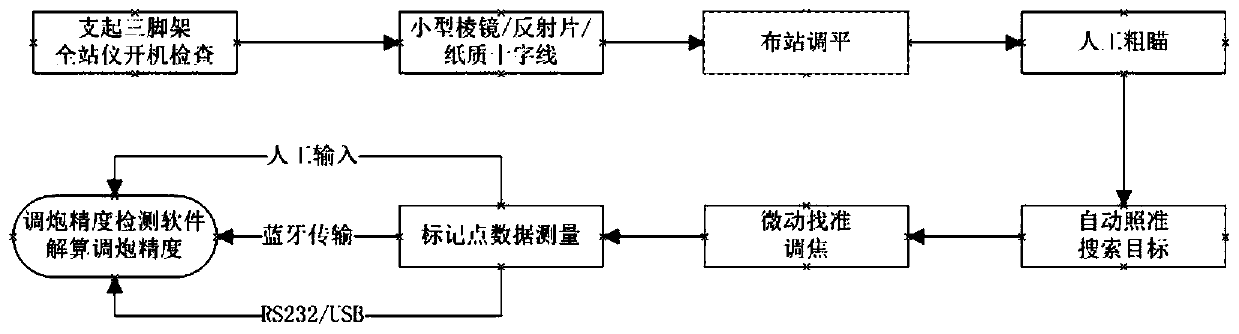

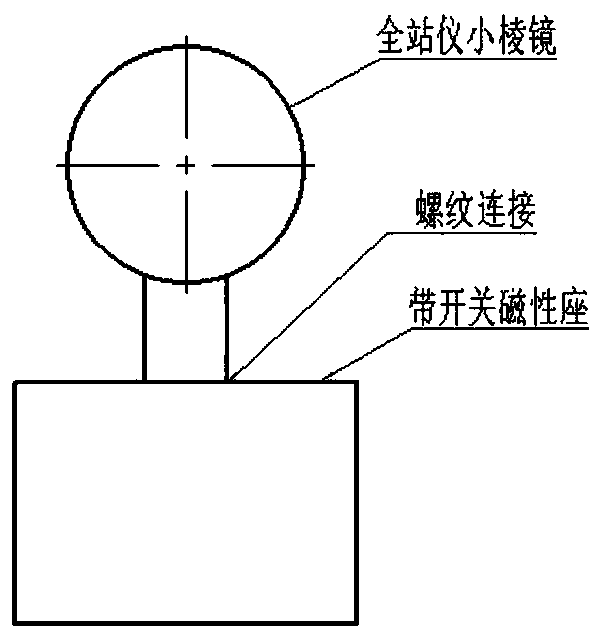

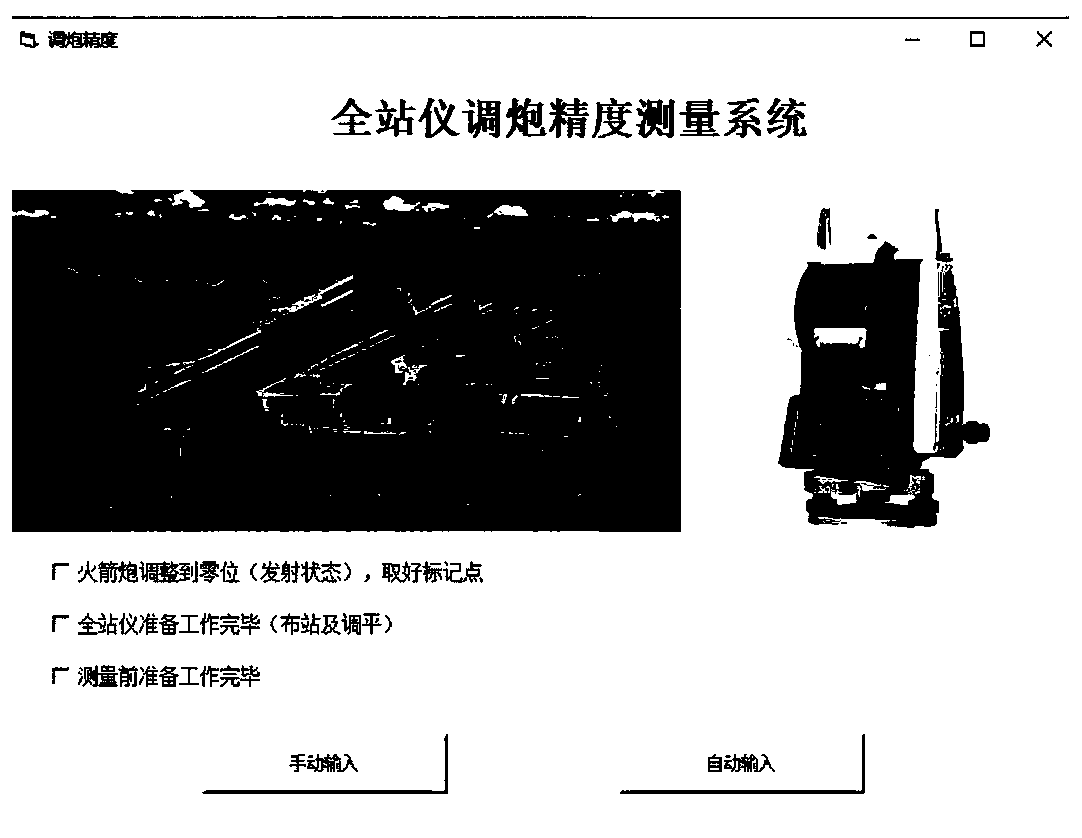

[0024] The invention discloses a semi-automatic gun adjustment accuracy detection system based on bluetooth wireless data transmission. figure 1 for its detection process. The first step is to put the tripod fixing seat, set up the tripod, install the total station, and start the inspection. The second step is to select two marker points P on the gun barrel or rocket launcher directional device 1 and P 2 . Due to the large size of the prism adapted to the traditional total station and it is inconvenient to install on the barrel of the weapon, it is designed figure 2 The small easy-installation prism shown is mainly characterized by the use of a small prism, which is connected to the magnetic base with a switch by thread, and installed on the gun barrel through the magnetic base. Two small easy-installation prisms are required for the front and rear marking points ;In the measurement mode with prism, the measurement accuracy of the total station is the highest. When the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com