Acceleration monitoring based roughness prediction method for side milling surface of thin-walled workpiece

A technology for surface roughness and thin-walled parts processing, which is applied in the field of surface roughness prediction for side milling of thin-walled parts based on monitoring acceleration, can solve problems such as poor practicability, and achieve low cost, simple method, small quality and volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

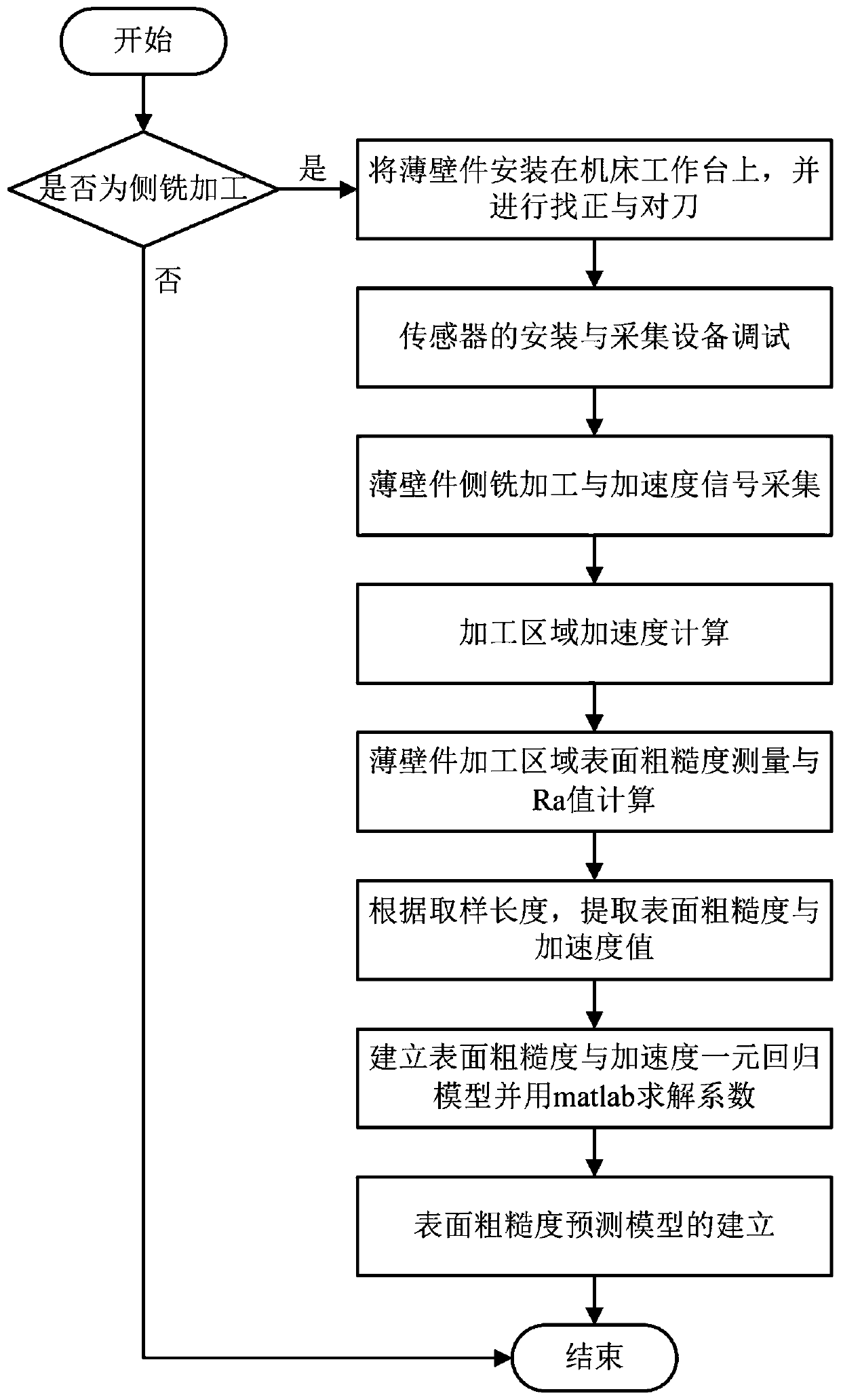

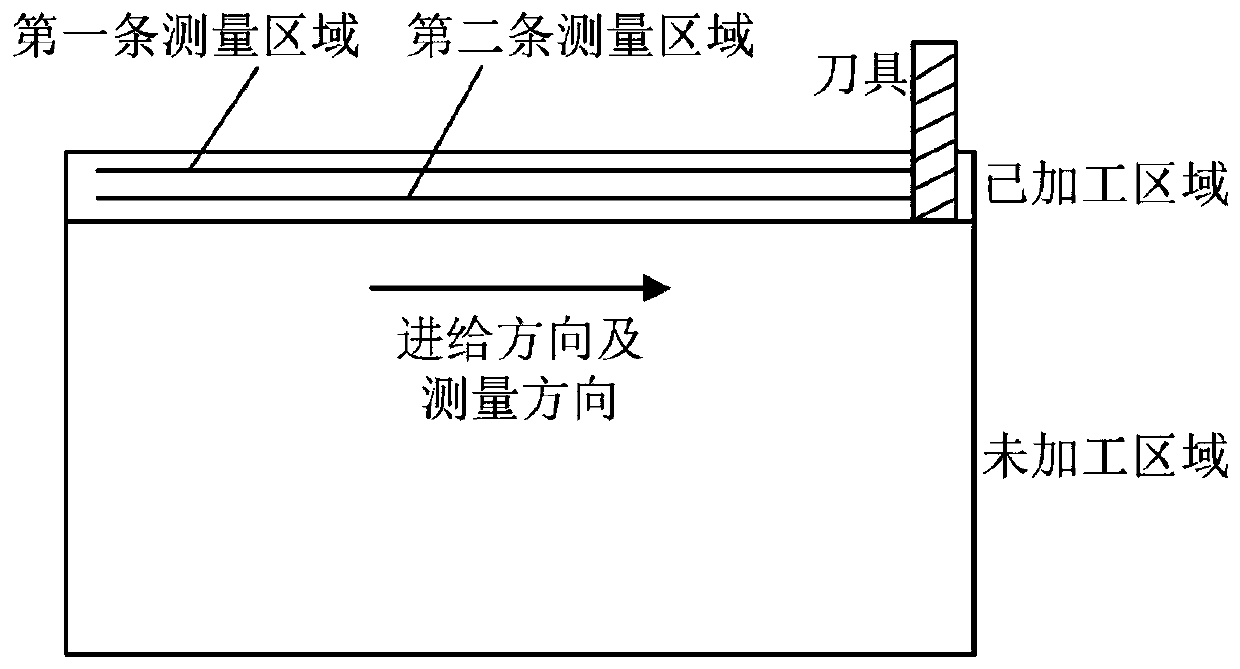

[0037] refer to Figure 1-4 . The specific steps of the surface roughness prediction method for side milling of thin-walled parts based on the monitoring acceleration of the present invention are as follows:

[0038] Step 1. Determine whether the processing method of the thin-walled part is side milling. If it is side milling, proceed to the second step; otherwise, this method is not applicable. This experiment uses side milling, so the second step can be performed.

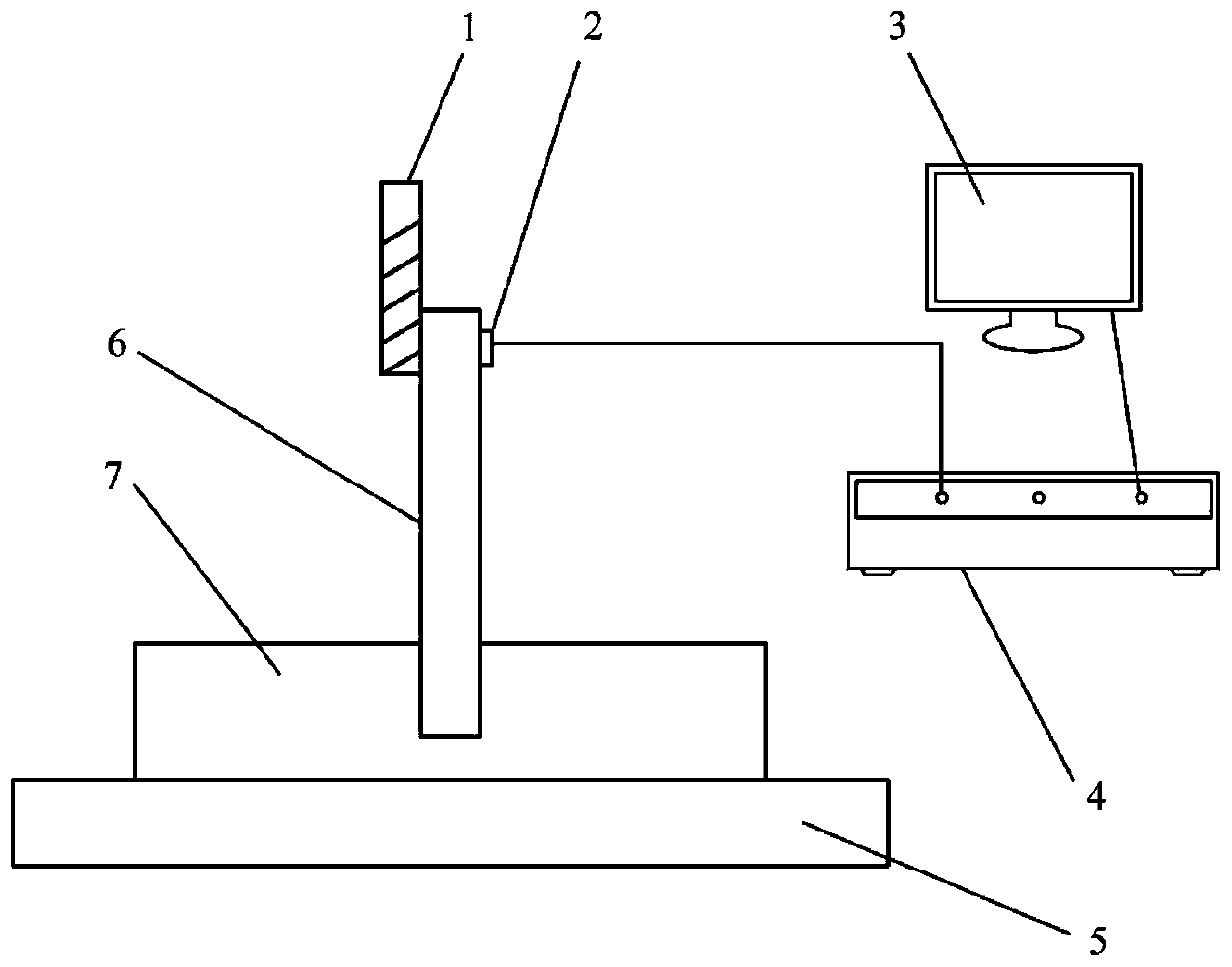

[0039] Step 2. Install the thin-walled part 6 on the fixture 7 of the machine tool table 5. The thin-walled part 6 used in this experiment is a titanium alloy with a size of 100mm×100mm×8mm and an aspect ratio of 12.5, which meets the requirement of the aspect ratio.

[0040] Step 3, the installation of the acceleration sensor 2 and the debugging of the acquisition equipment.

[0041]The acceleration sensor 2 is installed on the other side of the thin-walled part 6 to be processed in an axisymmetric position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com