Resin composition, production method for resin composition, and molded body using resin composition

A technology of resin composition and manufacturing method, which is applied to other household appliances, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of insufficient productivity and poor appearance of molded products, and achieve simple manufacturing, excellent appearance, The effect of increasing the ejection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] (1) Production of resin composition pellets

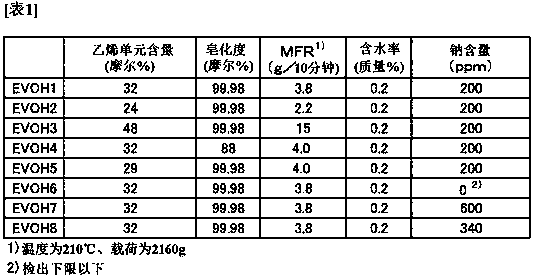

[0118] Prepare an ethylene unit content of 32 mol%, saponification degree of 99.98 mol%, MFR of 3.8g / 10min (at a temperature of 210°C, a load of 2160g), a water content of 0.2% by mass, and a metal salt containing 200ppm of acetic acid in terms of sodium Sodium EVOH1. In addition, as a nonionic surfactant, polyoxyethylene (7) stearyl ether (the number in parentheses in the compound name of the nonionic surfactant indicates the degree of condensation of polyoxyethylene units. The same applies hereinafter) was prepared. Water dispersion (content of nonionic surfactant: 10.0g / L). 100 parts by mass of EVOH1 and 1 part by mass of the above aqueous dispersion were blended. The resulting mixture was melt-kneaded under the following conditions, and then pelletized and further dried to obtain resin composition pellets.

[0119] Device: 25mmφ twin-screw extruder ("LABO PLASTOMILL 4C150" manufactured by Toyo Seiki Seisakusho)

[01...

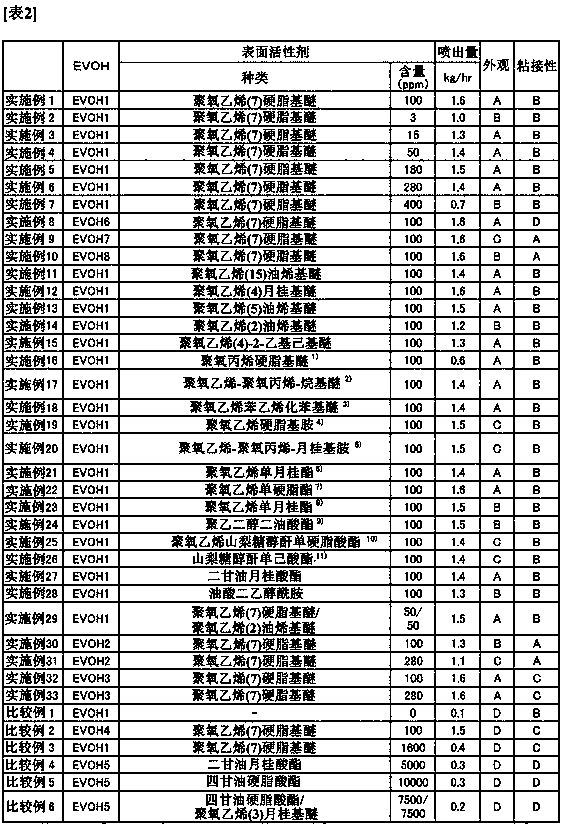

Embodiment 2~33 and comparative example 1~6

[0160] Except for changing the type of EVOH, the type and content of the nonionic surfactant as shown in Table 1 and Table 2, pellets, single-layer films, and multilayer structures of the resin composition were produced in the same manner as in Example 1. , to analyze and evaluate them. The results are shown in Table 2.

[0161]

[0162]

[0163]1) "UNILUB MS-70K" manufactured by NOF Corporation, 2) "NONION HT-510" manufactured by NOF Corporation, 3) "NOIGEN EA-157" manufactured by Daiichi Kogyo Manufacturing Co., Ltd., 4) manufactured by NOF Corporation "NOIGEN S-210", 5) NOIGEN L-703 manufactured by NOF Corporation, 6) "NONION L-4" manufactured by NOF Corporation, 7) "NONION S-4" manufactured by NOF Corporation, 8 ) "NONION L-2" manufactured by NOF Corporation, 9) "NONION DO-6" manufactured by NOF Corporation, 10) "SOLGEN TW-60" manufactured by Daiichi Kogyo Manufacturing Co., Ltd., 11) manufactured by Daiichi Kogyo Manufacturing Co., Ltd. "SOLGEN 110".

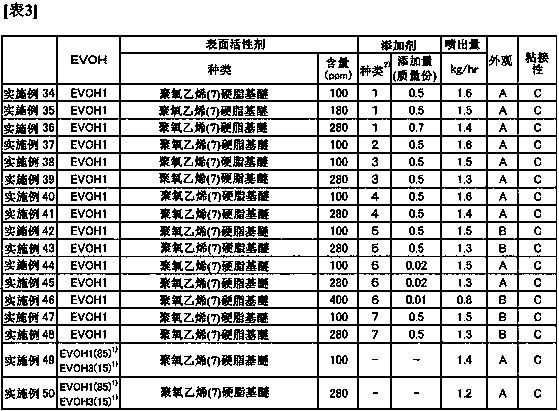

Embodiment 34

[0165] An aqueous dispersion of EVOH1 and a nonionic surfactant was prepared in the same manner as in Example 1. 100 parts by mass of EVOH1, 1 part by mass of the above aqueous dispersion and 0.5 parts by mass of N,N'-hexane-1,6-diyl bis[3-(3,5-di-tert-butyl-4 -Hydroxyphenyl) propionamide] for blending. Resin composition pellets, a single-layer film, and a multilayer structure were produced in the same manner as in Example 1 except that the mixture obtained in this way was used, and then their analysis and evaluation were performed. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com