High-efficiency integrated steel plate spring cropping, chamfering and hard-label-pressing mold

A technology of leaf spring and cutting head, which is applied in the field of high-efficiency integrated leaf spring cutting head, pressure angle and hard marking mold, can solve the problems of taking up more manpower and equipment, insufficient processing accuracy, and low product qualification rate, so as to reduce labor and labor costs. The effect of high equipment, high pass rate and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

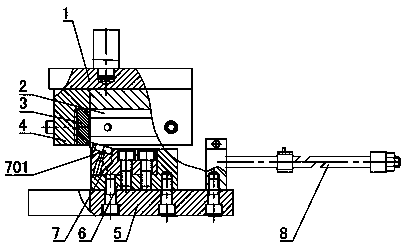

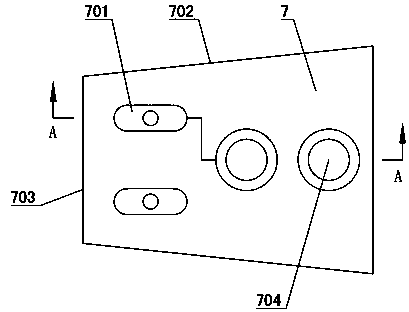

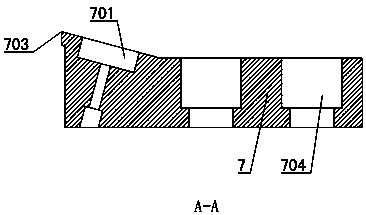

[0024] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0025] A high-efficiency integrated steel plate spring cutting head corner pressing hard marking die, including a head cutting knife 3 and a corner cutting knife 2 installed on the lower side of an upper template 1, a lower knife 7 installed on the upper side of a lower template 5, and a positioning mechanism 8. There are two corner knives 2 symmetrically arranged on the left and right sides of the upper template 1, and the corner knives 2 are gradually inwardly inclined from front to back, the head cutter 3 is arranged on the rear side of the lower template 5, and the bottom of the lower knife 7 The left and right sides are all provided with the corner cutting edge 702 that matches with the corner cutting knife 2, and the rear side of the lower knife 7 is provided with the cutting edge 703 that matches the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com