Robot automatic-welding device for single-face welding and dual-face forming of unequal-interval work piece

A technology of automatic welding and single-sided welding, applied in welding equipment, welding accessories, manufacturing tools, etc., to achieve the effect of reducing labor intensity, improving welding quality, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

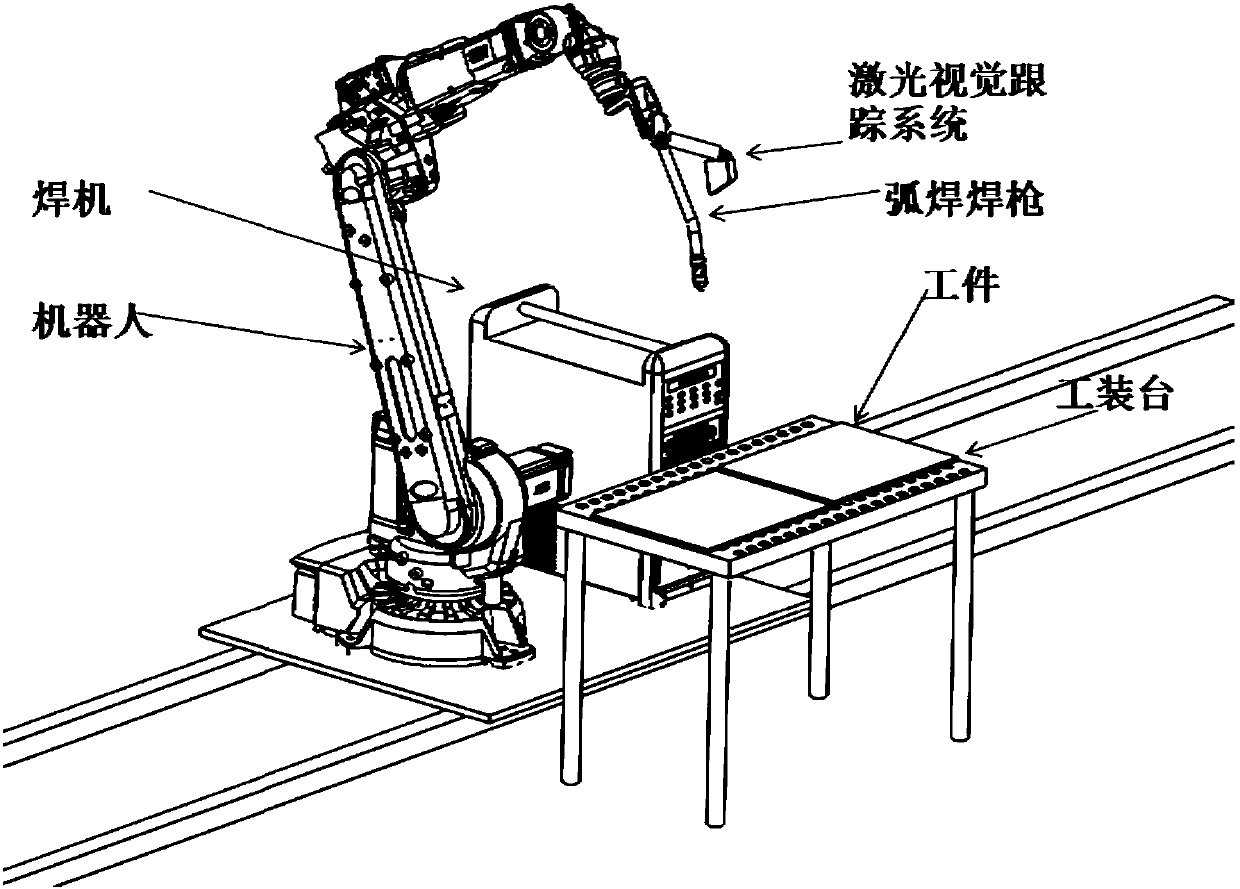

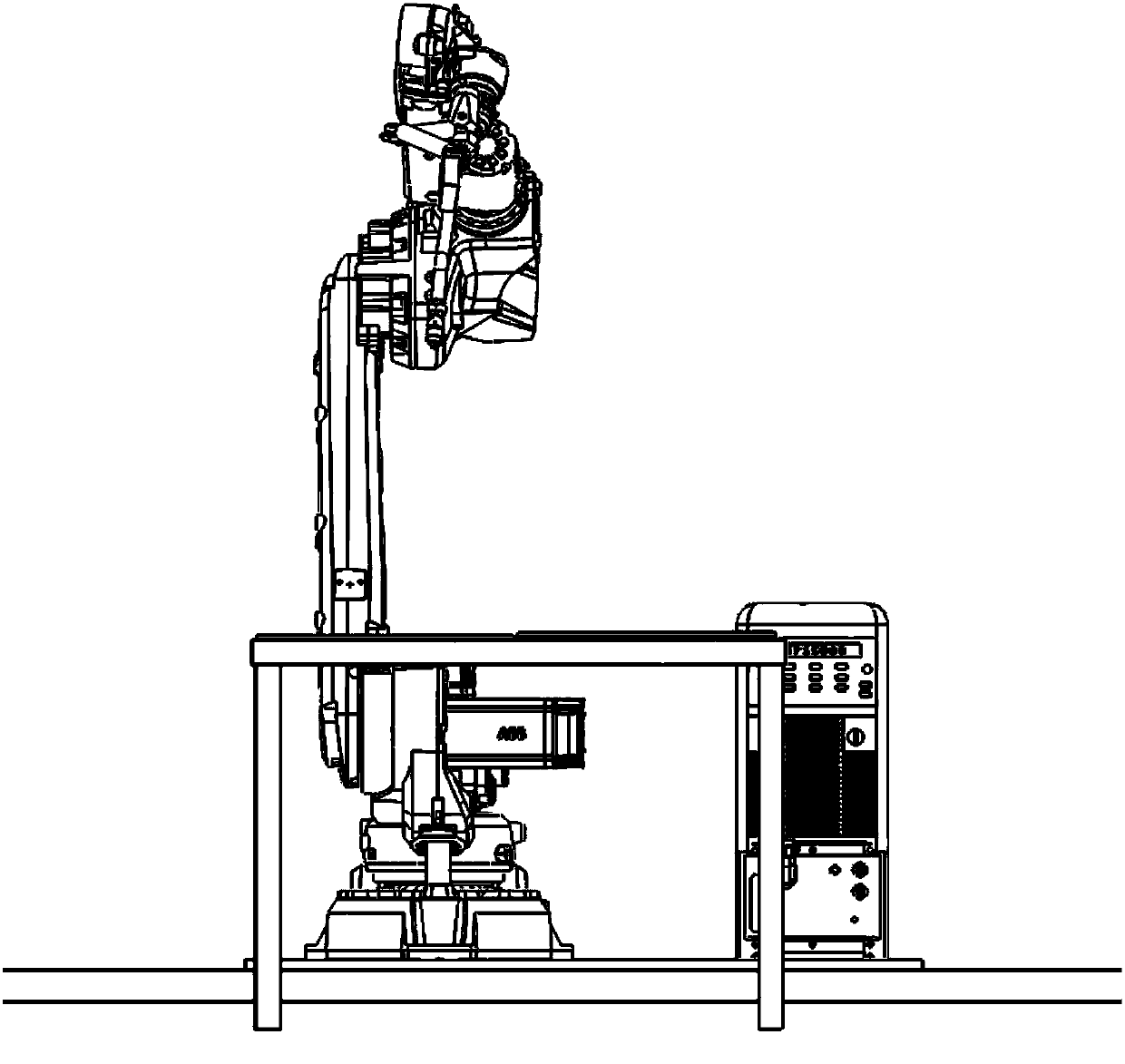

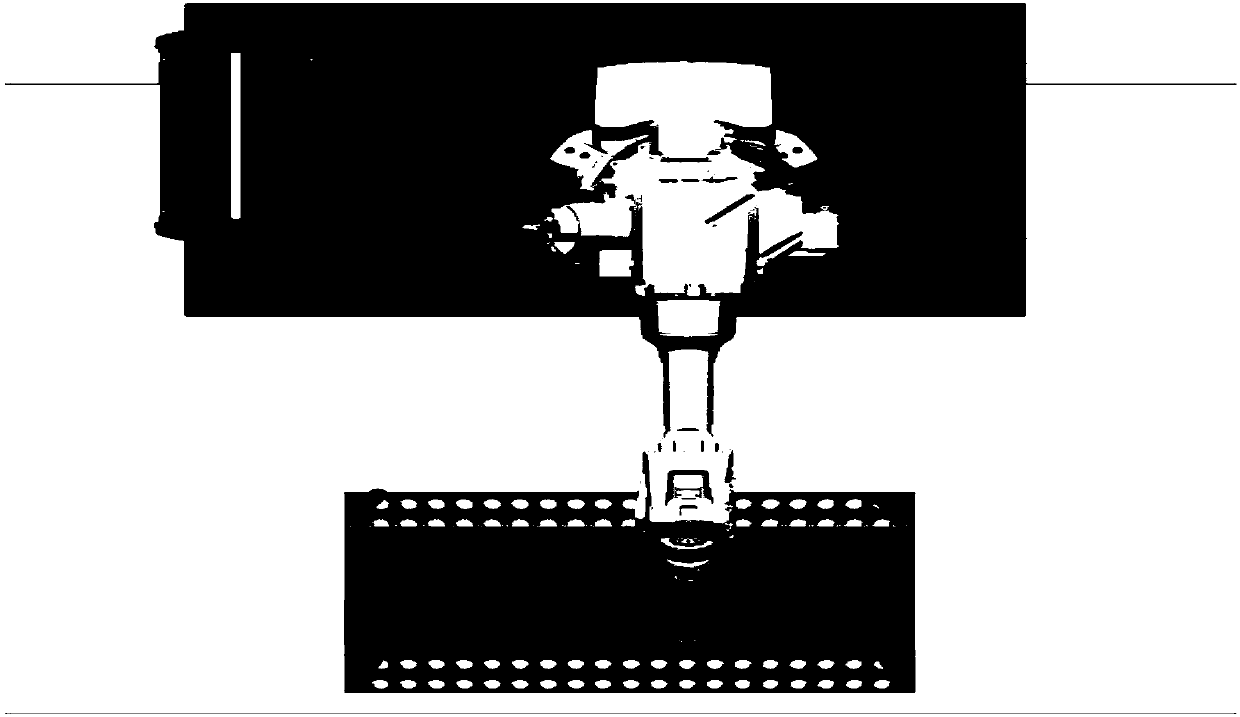

[0023] The technical solution of the present invention will be described in detail below with reference to the drawings in the specification.

[0024] The detailed features and advantages of the present invention will be described in detail below in the specific embodiments. The content is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the specification, claims and drawings disclosed in this specification Those skilled in the art can easily understand the related objectives and advantages of the present invention.

[0025] The invention is mainly a new and practical welding process, which can realize the automatic welding of V-grooved workpieces with unequal gaps on one side and double-side forming. The automatic welding device for single-side welding and double-side forming of unequal gap workpieces has The welding path is planned by teaching and programming in advance, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap