Air inlet and outlet end port machining device of automobile intercooler

A technology of processing device and intercooler, which is applied to grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of poor adjustment effect and low grinding efficiency of tracheal ports, and achieve the grinding effect. Good, stable effect of grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

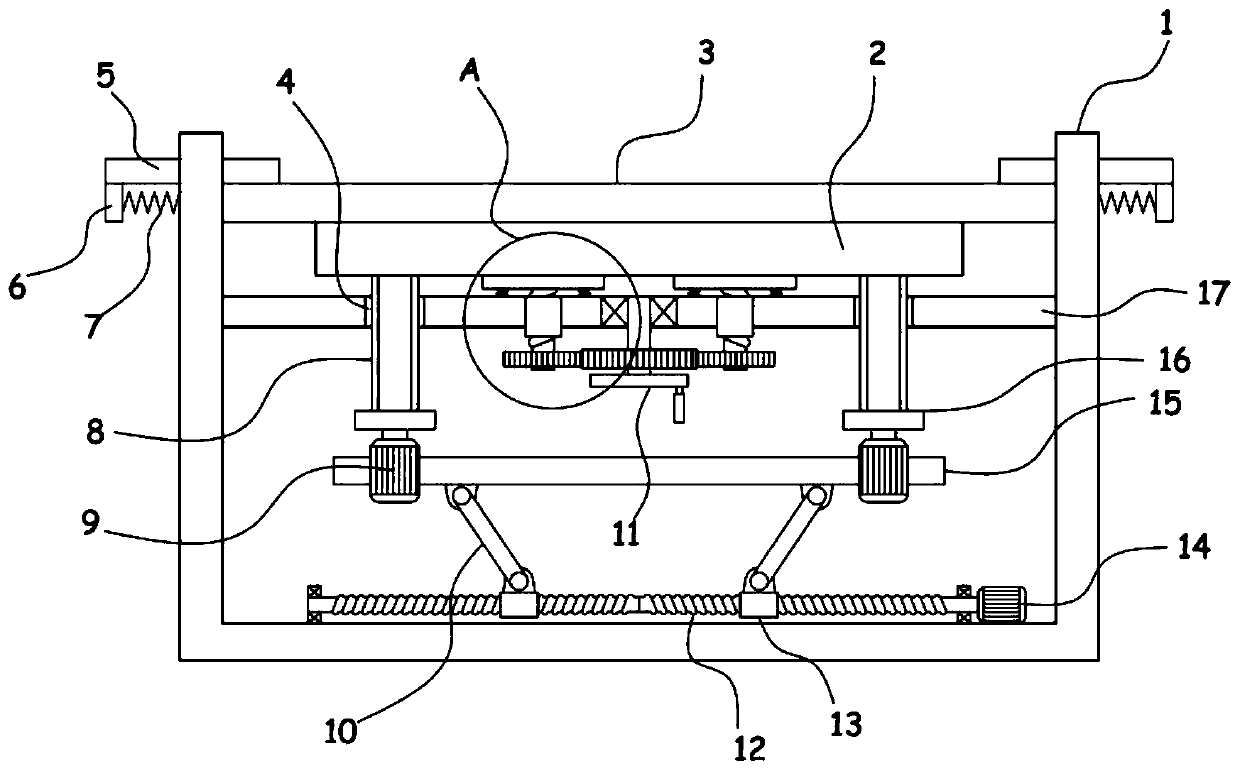

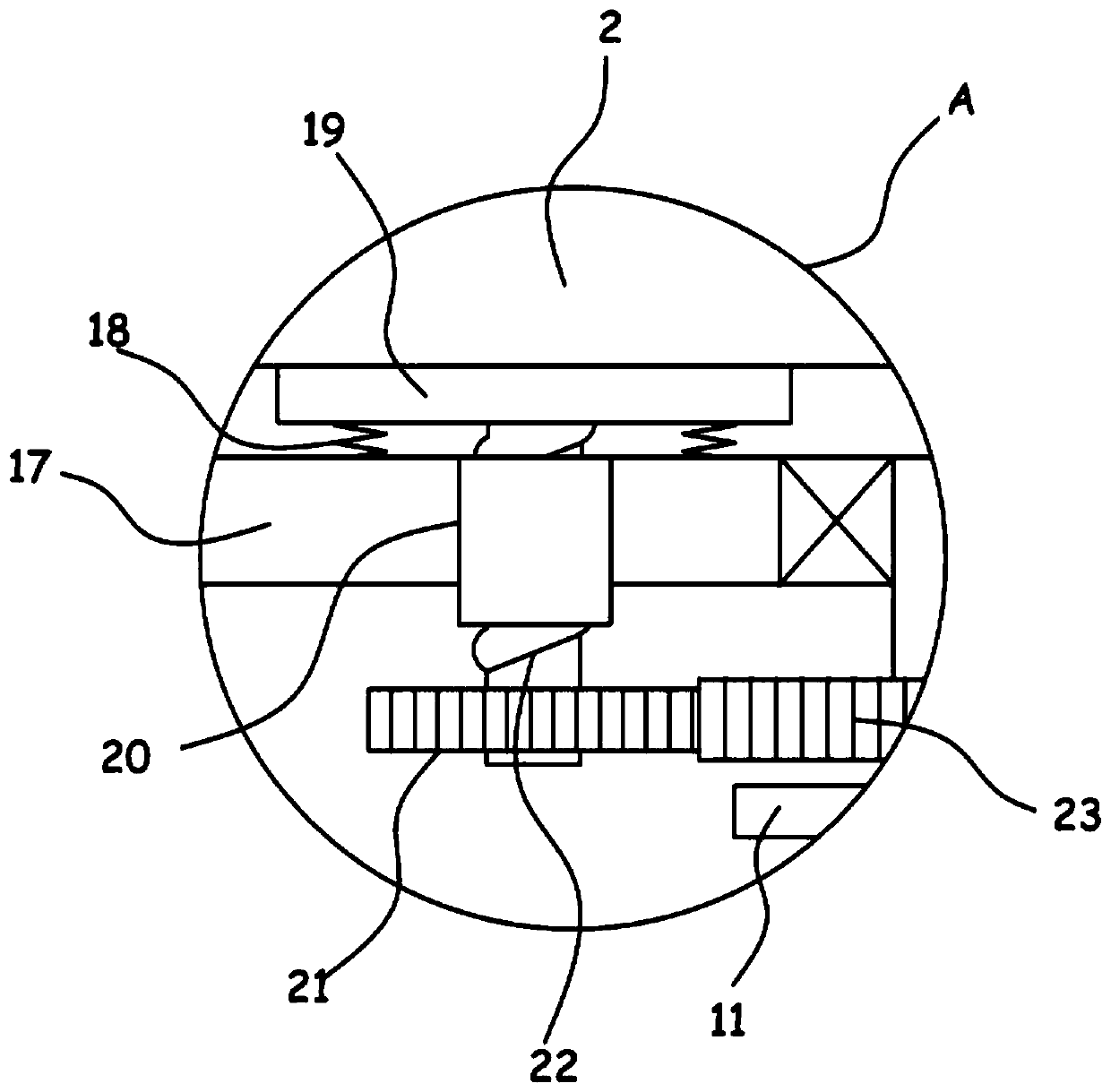

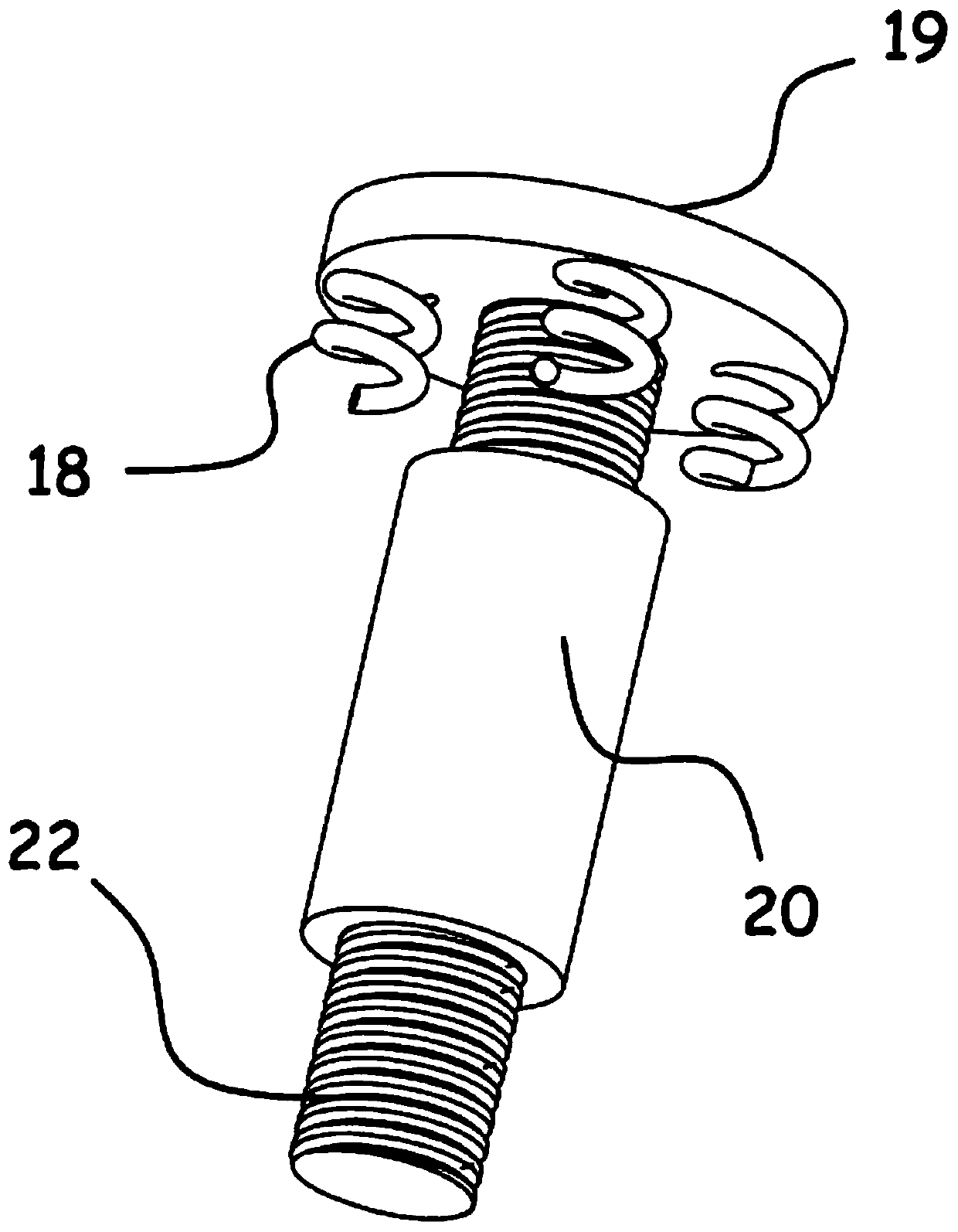

[0020] see Figure 1-3 , a processing device for the air inlet and outlet ports of an automobile intercooler, comprising a fixed frame 1, a fixed plate 17 for supporting the intercooler 2 is fixed on the fixed frame 1, and a gas pipe 8 for the intercooler 2 is opened on the fixed plate 17. The through hole 4 of the intercooler 2 is provided with an upper limit mechanism, and the fixed plate 17 is connected with a top plate 19 for pushing the intercooler 2 from bottom to top through a lower limit mechanism on the fixed plate 17. The fixed frame 1 A leveling mechanism for grinding the grinding disc 16 is connected to the top by a lifting mechanism.

[0021] The fixed plate 17 provided in this device is used to place the intercooler 2, the air pipe 8 on the intercooler 2 passes through the through hole 4 and extends downward, and the intercooler 2 is controlled by the upper limit mechanism and the lower limit mechanism provided. Clamp and fix to ensure that the position of the i...

Embodiment 2

[0026] In order to ensure that the position of the intercooler 2 is stable during the grinding process of the port of the air pipe 8, on the basis of Embodiment 1, in addition, the upper limit mechanism includes a pressure plate 3 that is pressed on the upper surface of the intercooler 2, and the side wall of the fixing frame 1 slides A slide plate 5 abutting against the upper surface of the pressure plate 3 is installed, a fixed block 6 is fixed at the lower end of the slide plate 5 , and a return spring 7 is fixedly connected between the fixed block 6 and the fixed frame 1 .

[0027] The set slide plate 5 clamps the pressure plate 3, and under the elastic action of the return spring 7, the fixed block 6 drives the slide plate 5 to penetrate the fixed frame 1 and limit the position of the pressure plate 3, so as to ensure that the intercooler 2 can be limited by the pressure plate 3 .

[0028] In addition, this device is also provided with a lower limit mechanism including a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com