Bearing roller ball base surface superfinishing mechanism

A technology of bearing rollers and ball bases, which is applied in the field of superfinishing of bearing rollers and ball bases, can solve problems such as limiting the machining accuracy of superfinishing machines, mutual interference, and reduced machining accuracy of roller ball bases, and achieves improved The effect of improving the processing quality of rollers, improving the processing accuracy, and improving the super precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

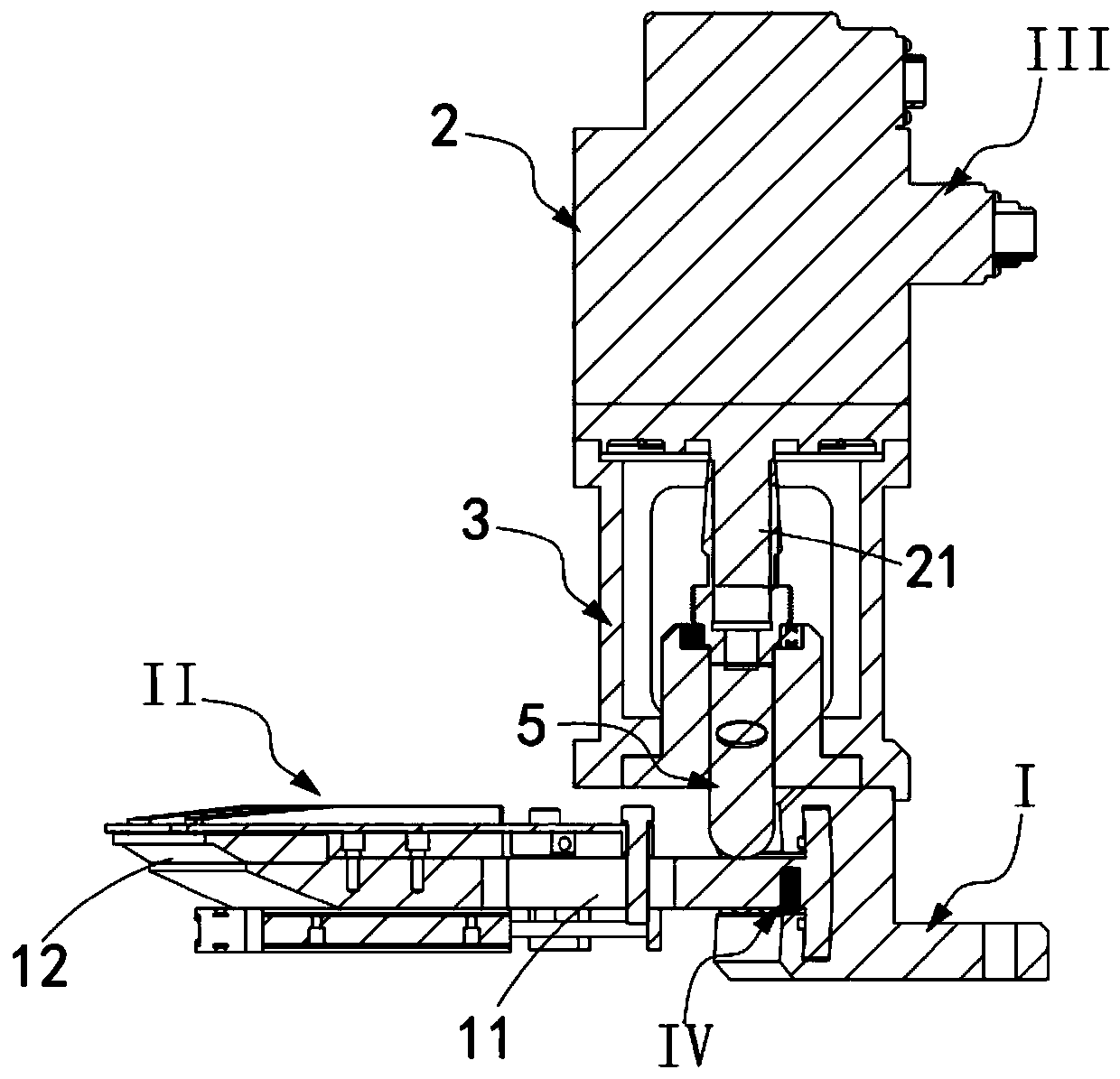

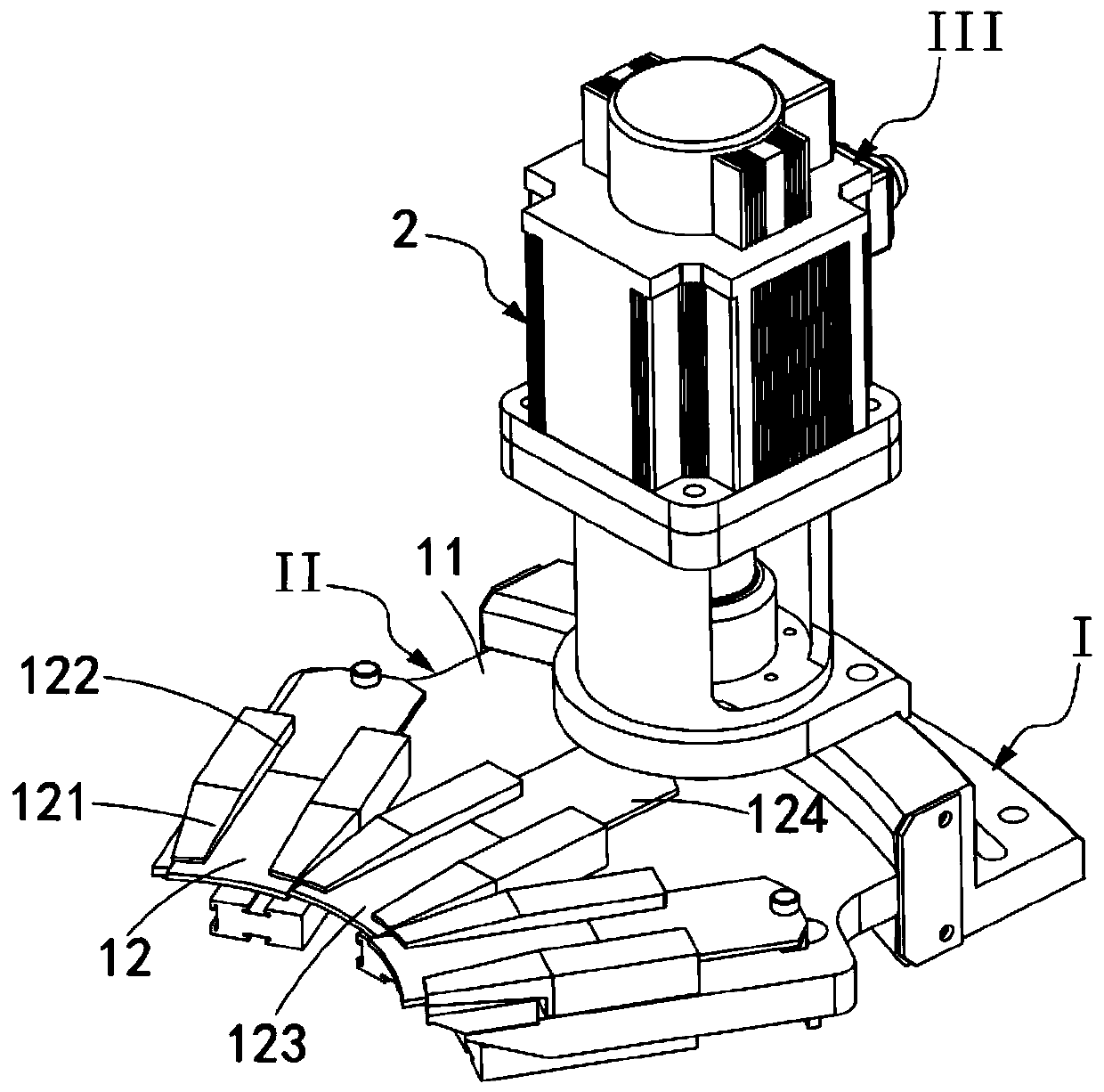

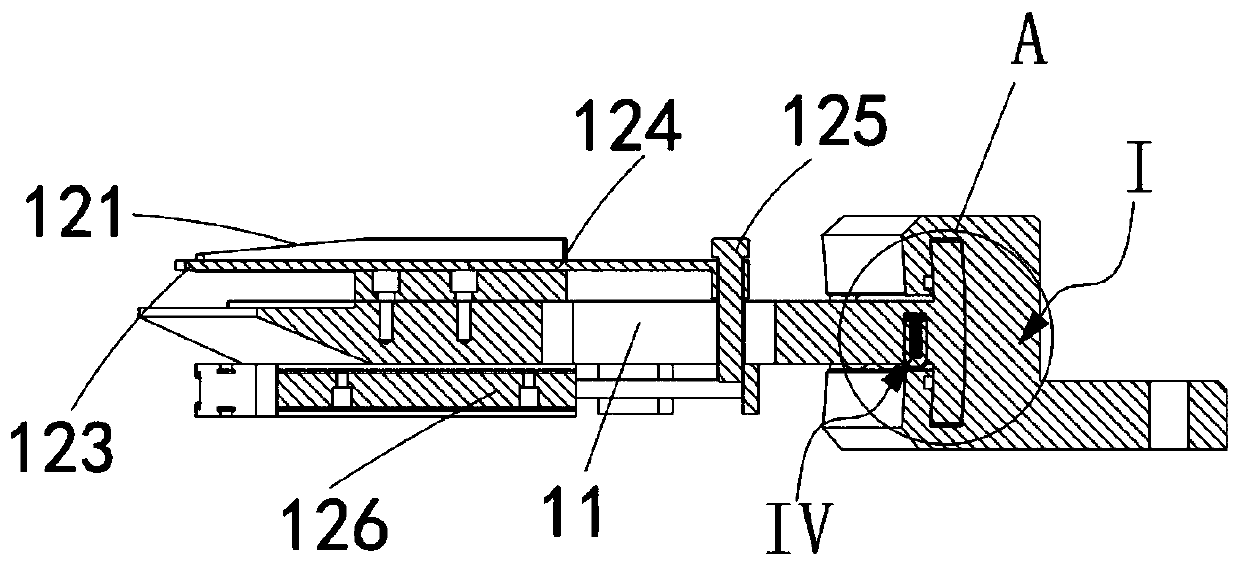

[0057] Such as Figure 1 to Figure 8 As shown, a bearing roller ball base surface super-precision mechanism includes a mounting base I and a super-precision component II installed on the mounting base I, and also includes an oscillating component III and a reset component IV;

[0058] The ultra-precision component II includes a shroud 11 installed on the installation base I and at least one set of ultra-precision units 12, the shroud 11 is vertically movable relative to the installation base I, and the The ultra-precision unit 12 is arranged along the side of the surrounding plate 11 close to the base surface of the roller ball to be super-precision, and the other side edge of the surrounding plate 11 relative to the ultra-precision unit 12 is installed to always conflict with the mounting seat I. The coordinated reset component IV;

[0059] The oscillating assembly III is installed on the mounting base I, which includes a vertically arranged rotary drive device 2, an amplitu...

Embodiment 2

[0080] Figure 9 It is a structural schematic diagram of Embodiment 2 of a bearing roller ball base surface super-precision mechanism of the present invention; as Figure 9 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0081] Such as Figure 9 As shown, a bearing roller ball base superfine mechanism, the control part 41 is a ball installed on the lower end of the rotating shaft 21 .

[0082] It should be noted that, different from the first embodiment, the control part 41 in this embodiment is a ball structure, which is directly rolled and placed in the groove at the lower end of the rotating shaft 21 .

[0083] It should be noted that, compared with the control part 41 provided with bumps, the control part 41 ...

Embodiment 3

[0085] Figure 10 It is a structural schematic diagram of Embodiment 3 of a bearing roller ball base surface super-precision mechanism of the present invention; as Figure 10 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below.

[0086] Such as Figure 10 and Figure 11 As shown, a bearing roller base surface super-precision mechanism further includes an elastic connection assembly 6 coaxially sleeved on the outside of the rotating shaft 21 through a tapered structure.

[0087] Further, the control part 41 is a protrusion extending outward from the lower end of the elastic connection component 6 or a ball rotatably mounted on the lower end of the elastic connection component 6 .

[0088] It should be noted that, in this embodiment, the control unit 41 can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com