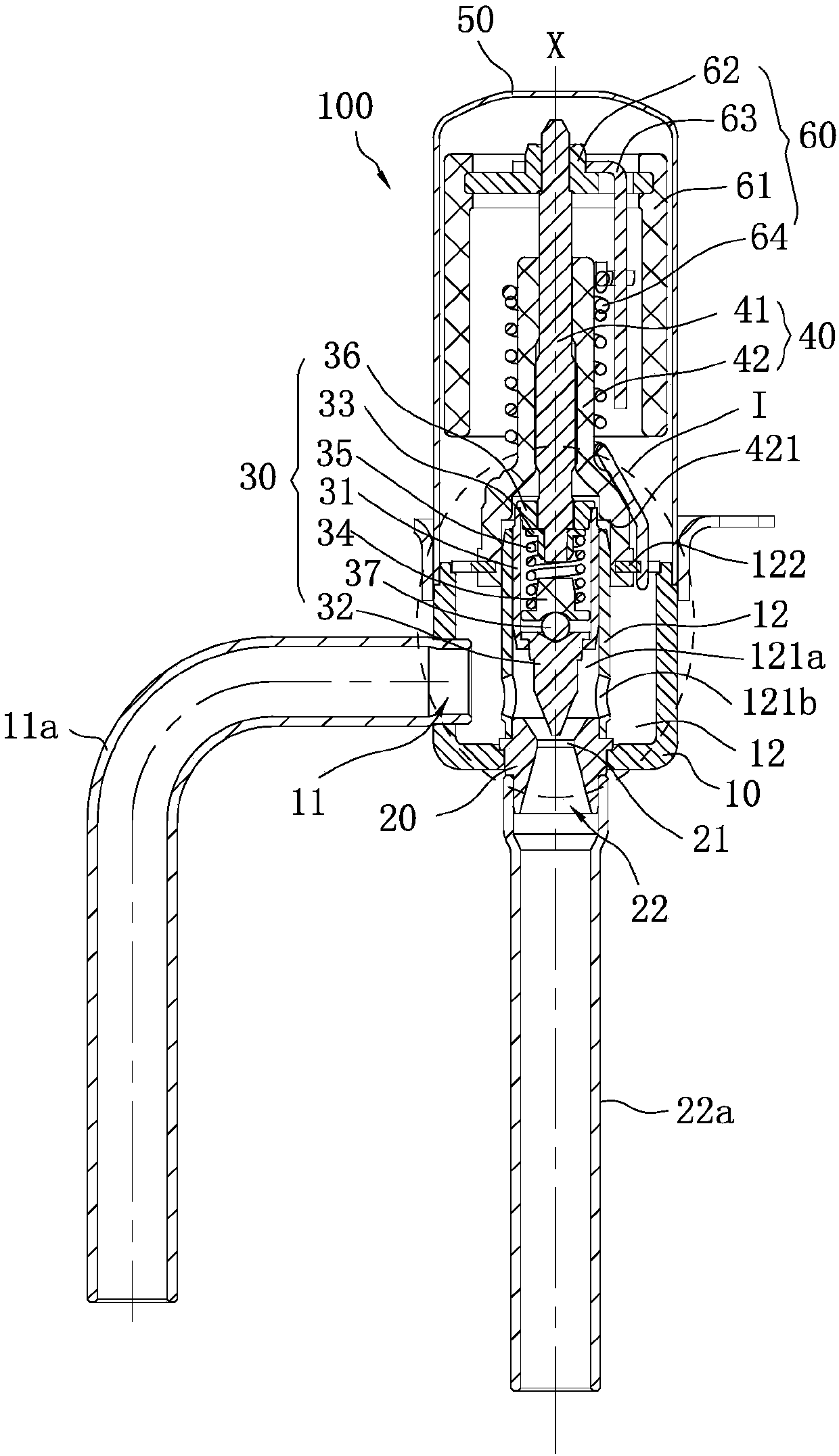

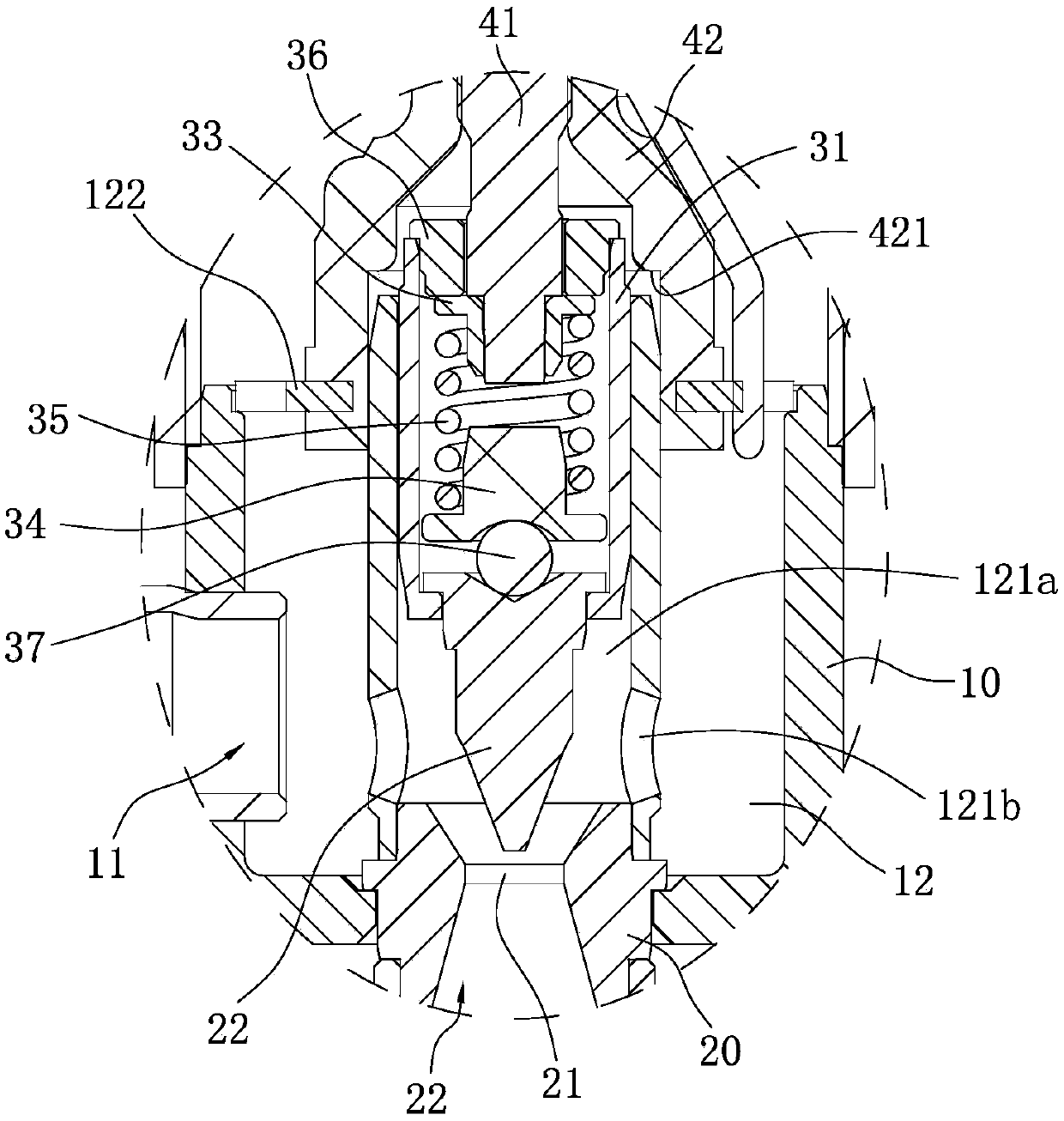

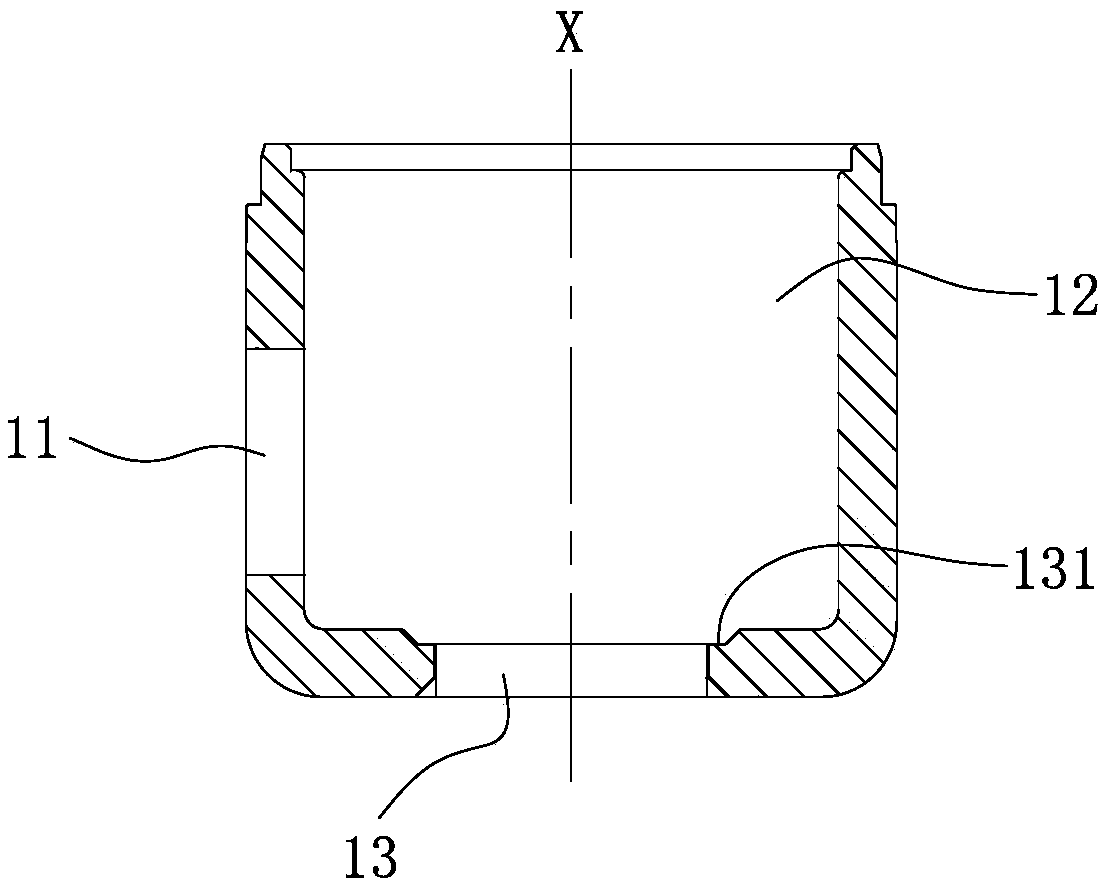

Electronic expansion valve and air-conditioning refrigeration system thereof

An electronic expansion valve and valve port technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of squealing sound and poor comfort of the valve body, and achieve the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1: The diameter of the valve port D=2.0mm, the flow volume at the valve port V=9.0m 3 / h, the aperture d of the distribution hole is respectively taken as: 2.7mm, 2.8mm, 2.9mm, 3.0mm, 3.1mm, 3.2mm, after testing, wait until the following data table.

[0062]

[0063] It can be seen from the above table that when the flow volume at the valve port V=9.0m 3 / h, the diameter of the valve port D=2.0mm; when the diameter d of the distribution hole is between 2.7mm-3.2mm, the refrigerant flowing from port A to port B is evenly distributed, and can achieve the purpose of throttling and pressure reduction; The flow from port B to port A is fluid sound.

Embodiment 2

[0064] Example 2: The diameter of the valve port D = 2.2mm, the flow volume at the valve port V = 11.0m 3 / h, the distribution holes are respectively taken: 2.7mm, 2.8mm, 2.9mm, 3.0mm, 3.1mm, 3.2mm, after testing, wait until the following data table.

[0065]

[0066]It can be seen from the above table that when the flow volume at the valve port V=11.0m 3 / h, the diameter of the valve port D=2.2mm; when the diameter d of the distribution hole is between 2.7mm-3.2mm, the refrigerant flowing from port A to port B is evenly distributed, and can achieve the purpose of throttling and reducing pressure; The flow from port B to port A is fluid sound.

Embodiment 3

[0067] Embodiment 3: The caliber of the valve port D=2.4mm, the flow volume V at the valve port=13.0m 3 / h, the distribution holes are respectively taken: 2.7mm, 2.8mm, 2.9mm, 3.0mm, 3.1mm, 3.2mm, after testing, wait until the following data table.

[0068]

[0069] It can be seen from the above table that when the flow volume at the valve port V=13.0m 3 / h, the diameter of the valve port D=2.4mm; when the diameter d of the distribution hole is in the range of 2.7mm-3.2mm, the refrigerant flowing from port A to port B is evenly distributed, and can achieve the purpose of throttling and pressure reduction; The flow from port B to port A is fluid sound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com