Multifunctional steel plate spring detection mandrel

A technology of leaf springs and detection cores, applied in measuring devices, instruments, etc., can solve the problems of difficult management, many models, inaccurate detection data, etc., and achieve the effects of accurate detection, convenient assembly, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

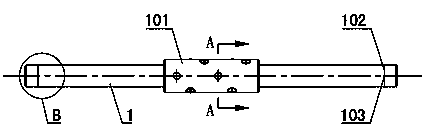

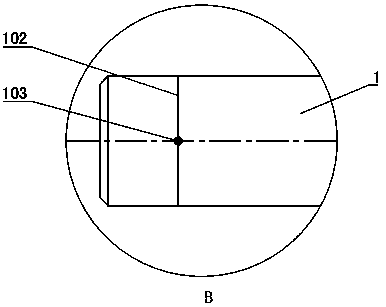

[0026] Such as Figure 1~3 As shown: the cross section of the mandrel body 1 is circular, and the middle part of the mandrel body 1 is provided with a detection part 101 whose diameter is larger than that of both ends. The length is less than the length of the mandrel body 1 on either side of the detection part 101 .

[0027] Both ends of the mandrel body 1 are symmetrically provided with ring-shaped measuring lines 102 around the mandrel body 1 , and the distances between the measuring lines 102 at both ends and the corresponding side of the detection part 101 are equal. One measuring point 103 is set on each measuring line 102 , and the line connecting the two measuring points 103 is set parallel to the axis of the mandrel main body 1 .

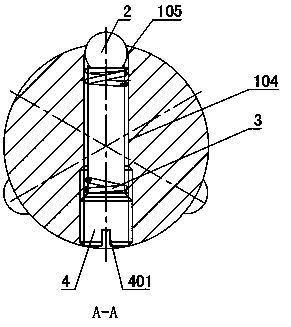

[0028] The mounting holes 104 are through holes arranged radially along the detection part 101. The mounting holes 104 are evenly distributed in three rows around the detection part 101. Each row is provided with two mounting holes 104, an...

Embodiment 2

[0033] The difference between Embodiment 2 and Embodiment 1 is that the installation hole 104 is a blind hole, one end of the spring 3 is supported on the bottom of the installation hole 104 , and the other end pushes the steel ball 2 to move outward and protrude out of the detection part 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com