Automatic sample preparation equipment

A technology of automatic sample preparation and equipment, which is applied to the preparation, sampling, and measuring devices of test samples, which can solve problems such as low efficiency, tedious sample preparation process, sample spilling, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

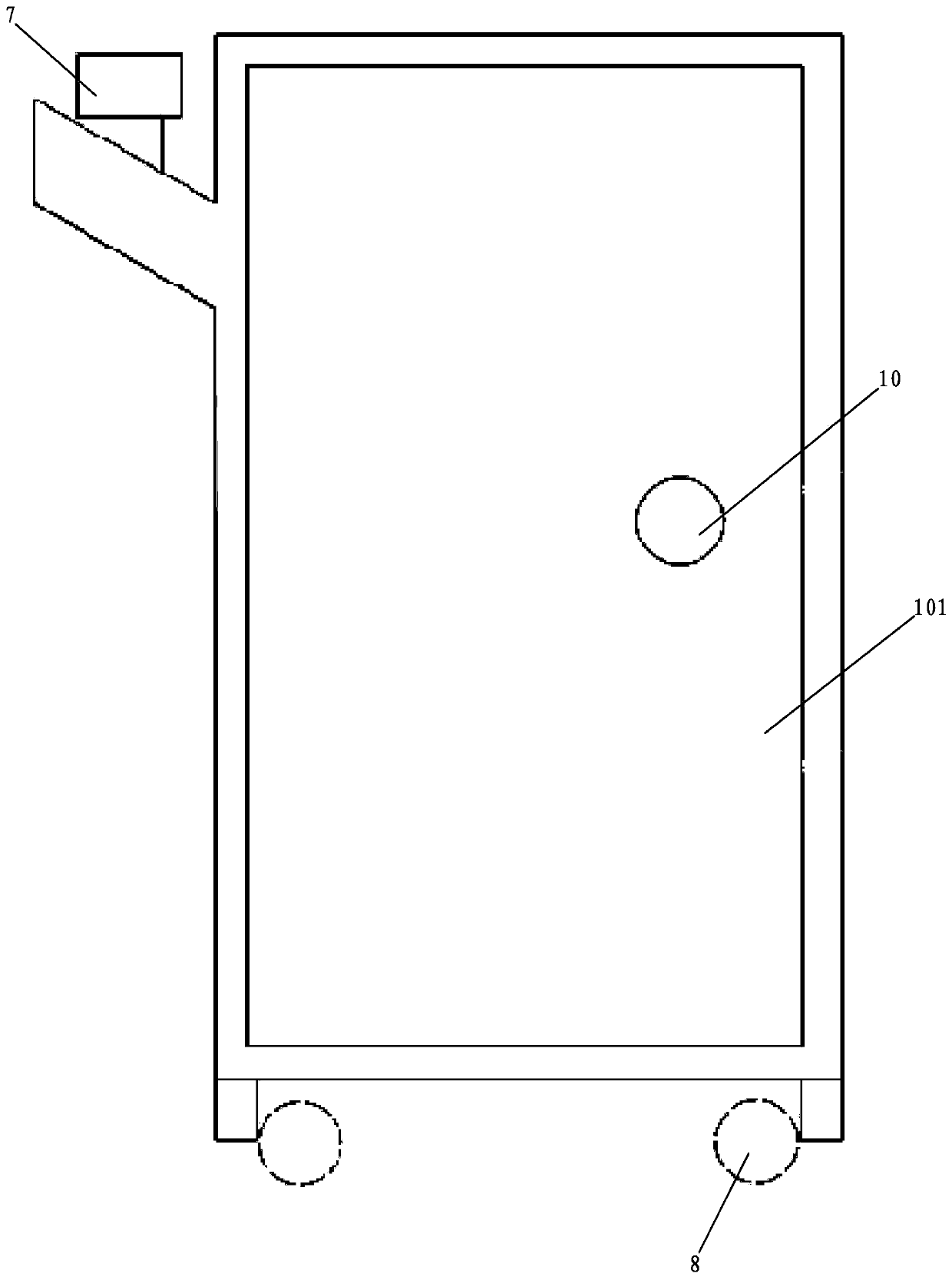

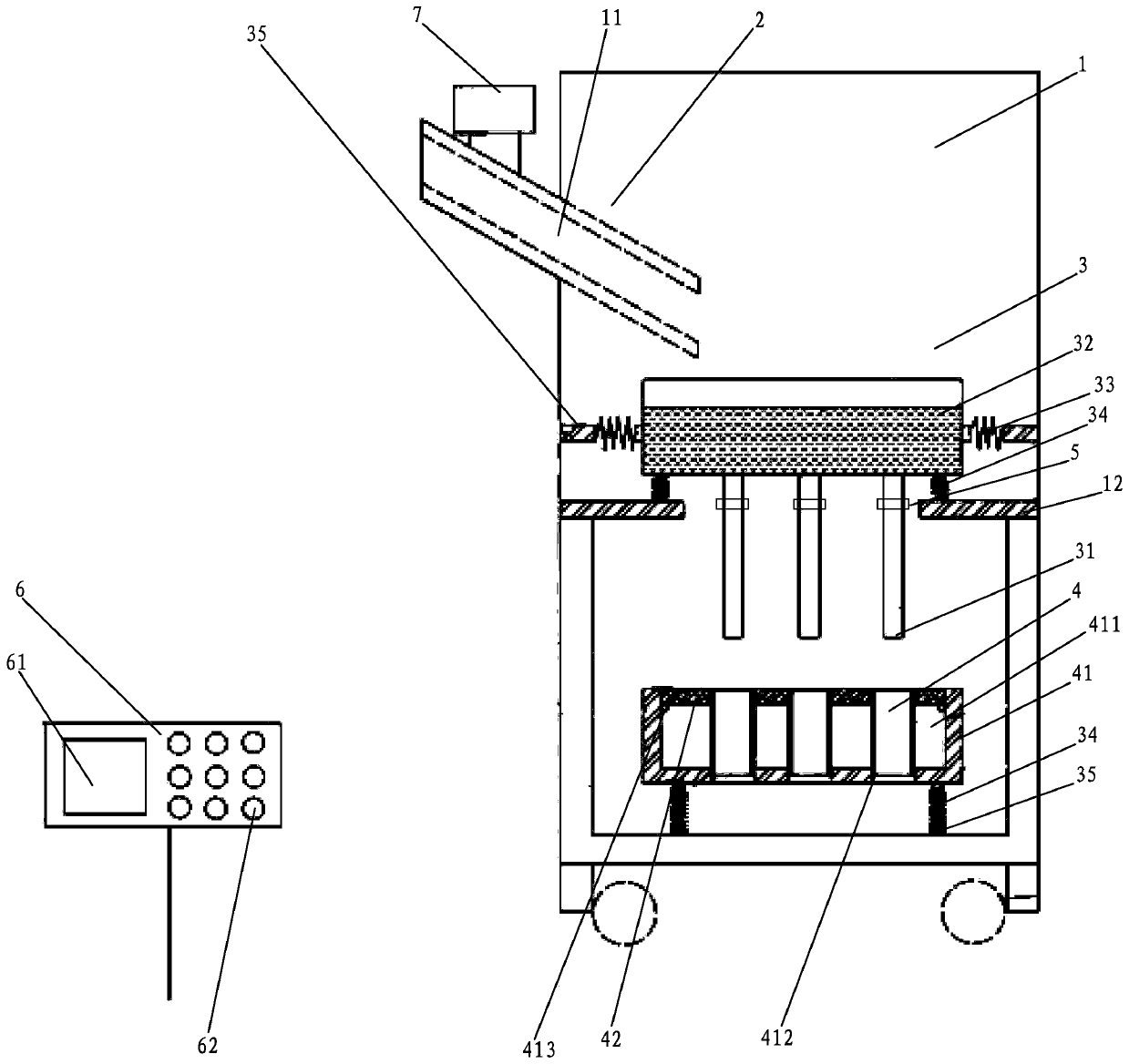

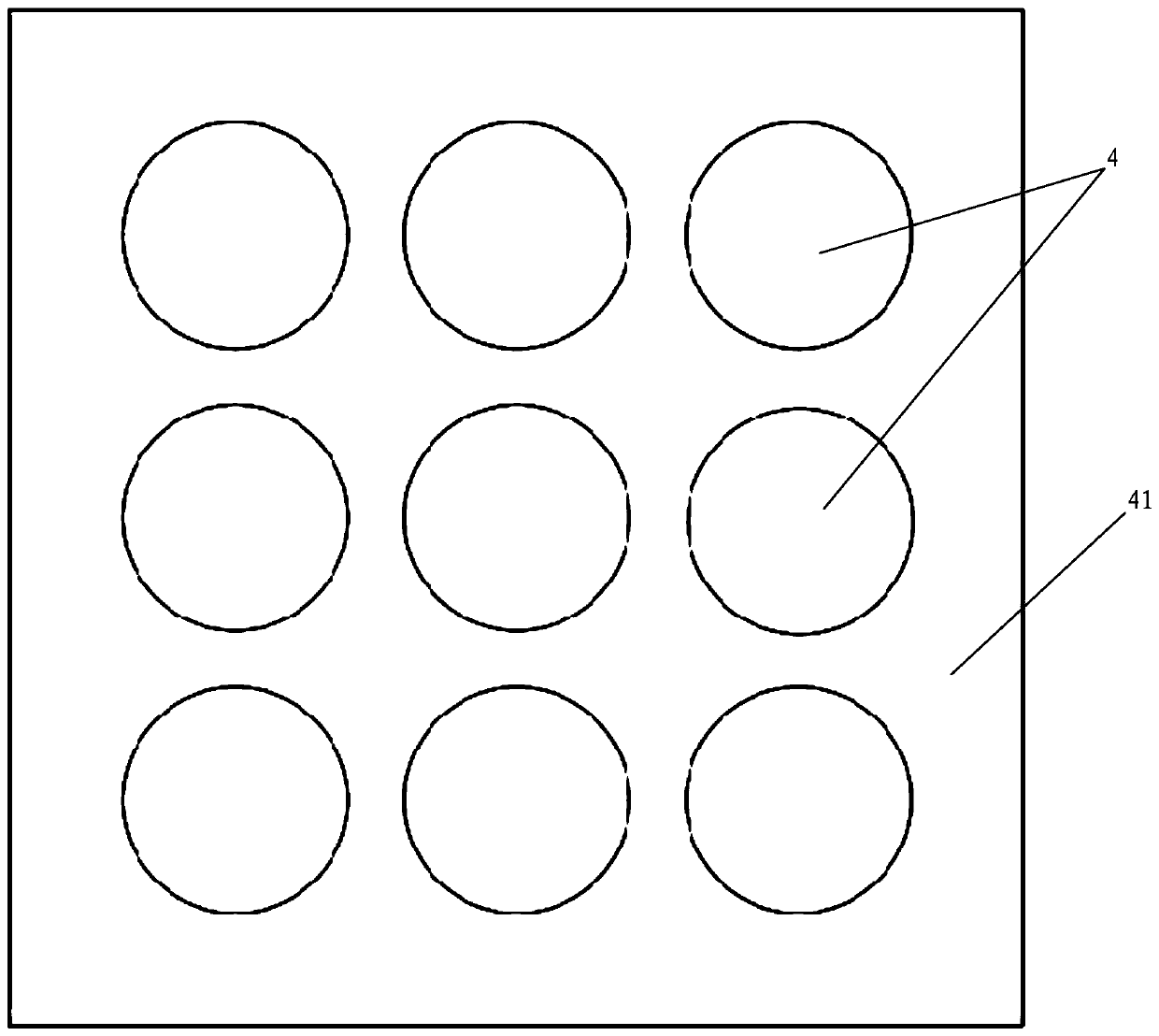

[0026] refer to Figure 1 to Figure 3 , this embodiment relates to automatic sample preparation equipment, including a box body 1, a conveying device 2, an oscillating mixing device 3, a three-lobe mold 4, a flow sensor 5, a switching valve and a controller 6, and a through hole is opened on the upper part of the box body 1 11. The conveying device 2 is set in the through hole 11, the oscillating mixing device 3 and the three-lobe mold 4 are set in the box body 1, and the oscillating mixing device 3 is set under the output end of the conveying device 2 to accept the The solid material required for the test delivered on the conveying device 2; the vibration mixing device 3 is provided with a plurality of discharge ports 31, and the three-lobe mold 4 is arranged below the discharge port 31 to accept the mixing from the vibration The solid material needed for the mixed and oscillating test delivered in the device 3; the quantity of the three-lobe mold 4 is equal to the quantity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com