Computer tomography device and method for determining an operating state of grinding contacts in a computer tomography device

A sliding contact, tomography technology, used in computer tomography scanners, instruments for radiological diagnosis, diagnosis, etc., can solve problems such as high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

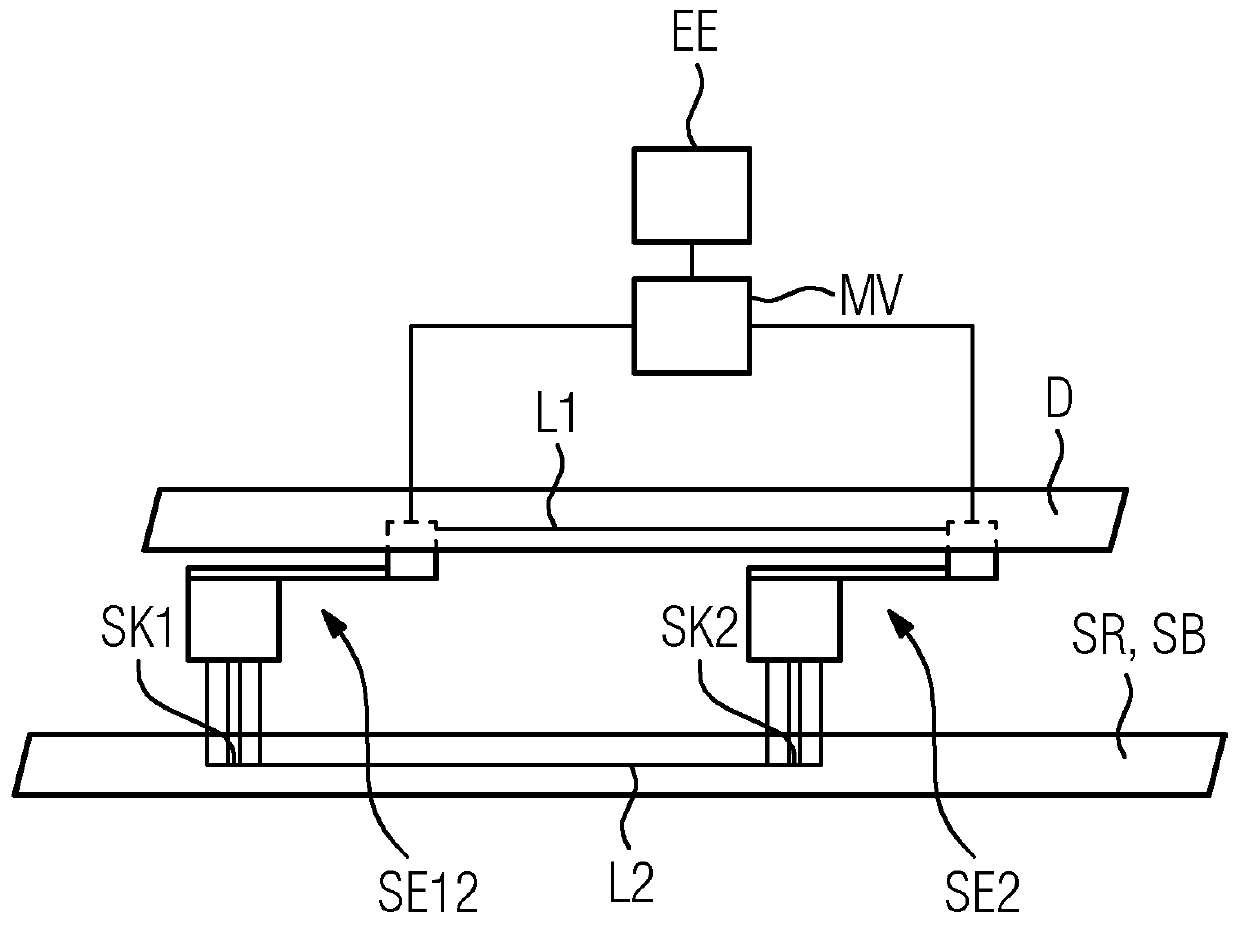

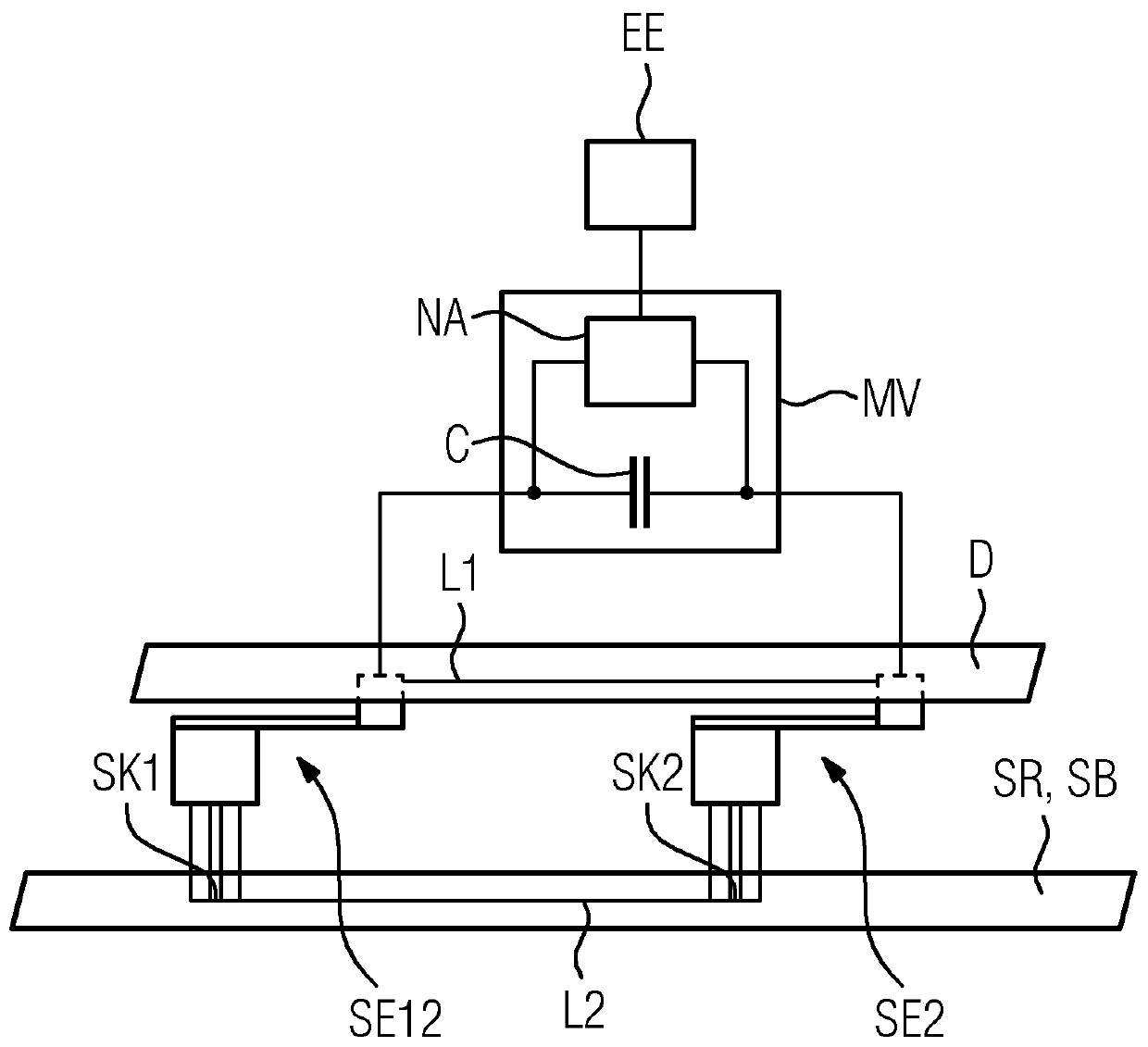

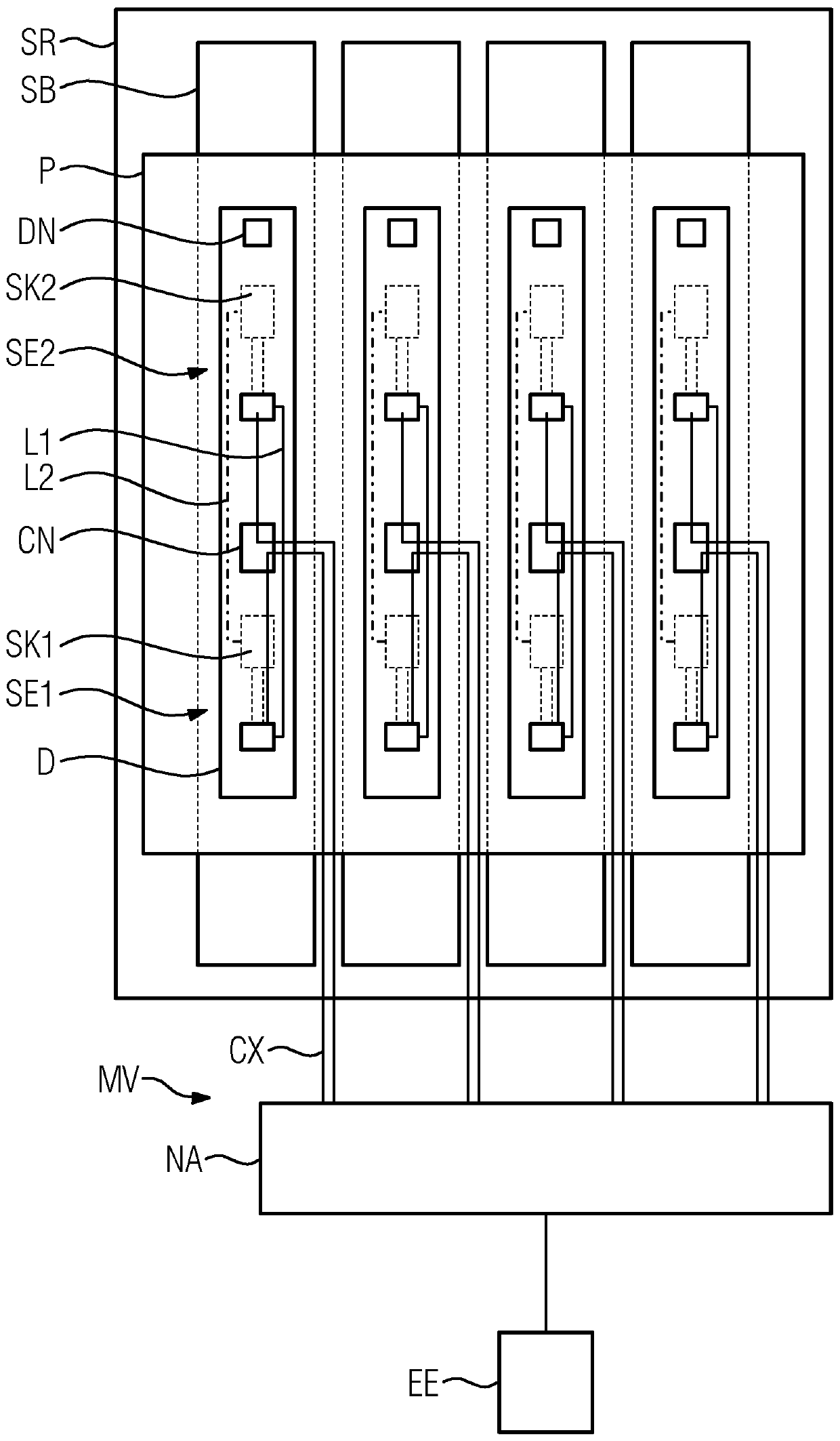

[0064] figure 1 Shown is a slip ring SR with a sliding track SB, a power supply line D, sliding contact elements SE1 and SE2, sliding contacts SK1 and SK2, a measuring device MV and a determination unit EE. The slip ring SR has a slide track SB and is rotatable relative to the feeder D. At the feed line D, two sliding contact elements SE1 and SE2 are arranged. Each of the two sliding contact elements SE1 and SE2 is designed as a brush, for example a carbon brush.

[0065] Each of the two sliding contact elements SE1 and SE2 is connected to the feeder D by means of a spring element and a contact pressure adjustment device, wherein the contact pressure adjustment device is designed to adjust the contact pressure of the brush on the sliding rail SB. One end of the spring element is fixedly connected to the feeder D. The other end of the spring element is fixedly connected to the brush. The spring element can have, for example, an elastic metal strip which is clamped in the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com