Cleaning device for conical flasks

A cleaning device and conical flask technology, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient cleaning, small contact area, long time consumption, etc., and achieve fast cleaning and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

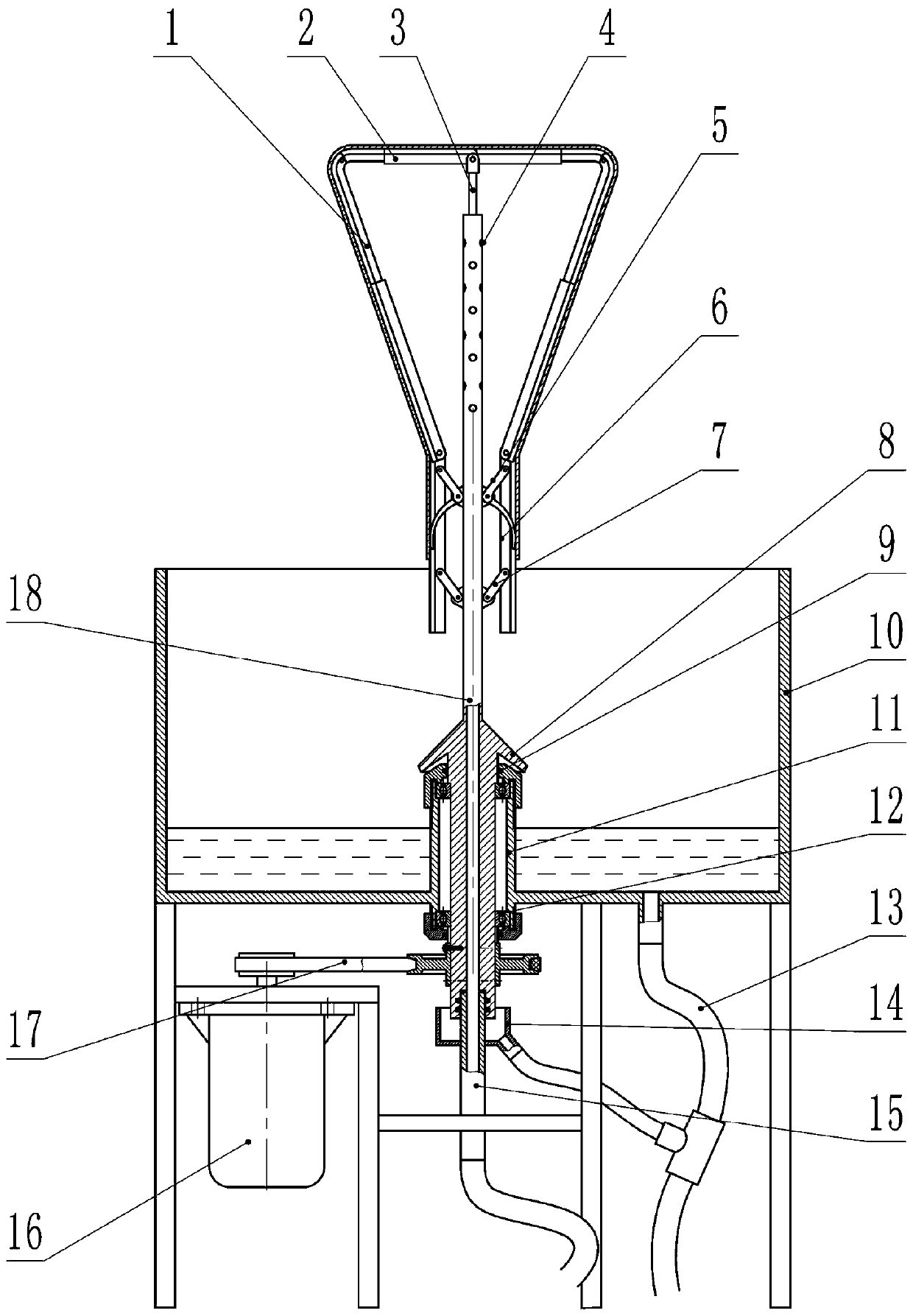

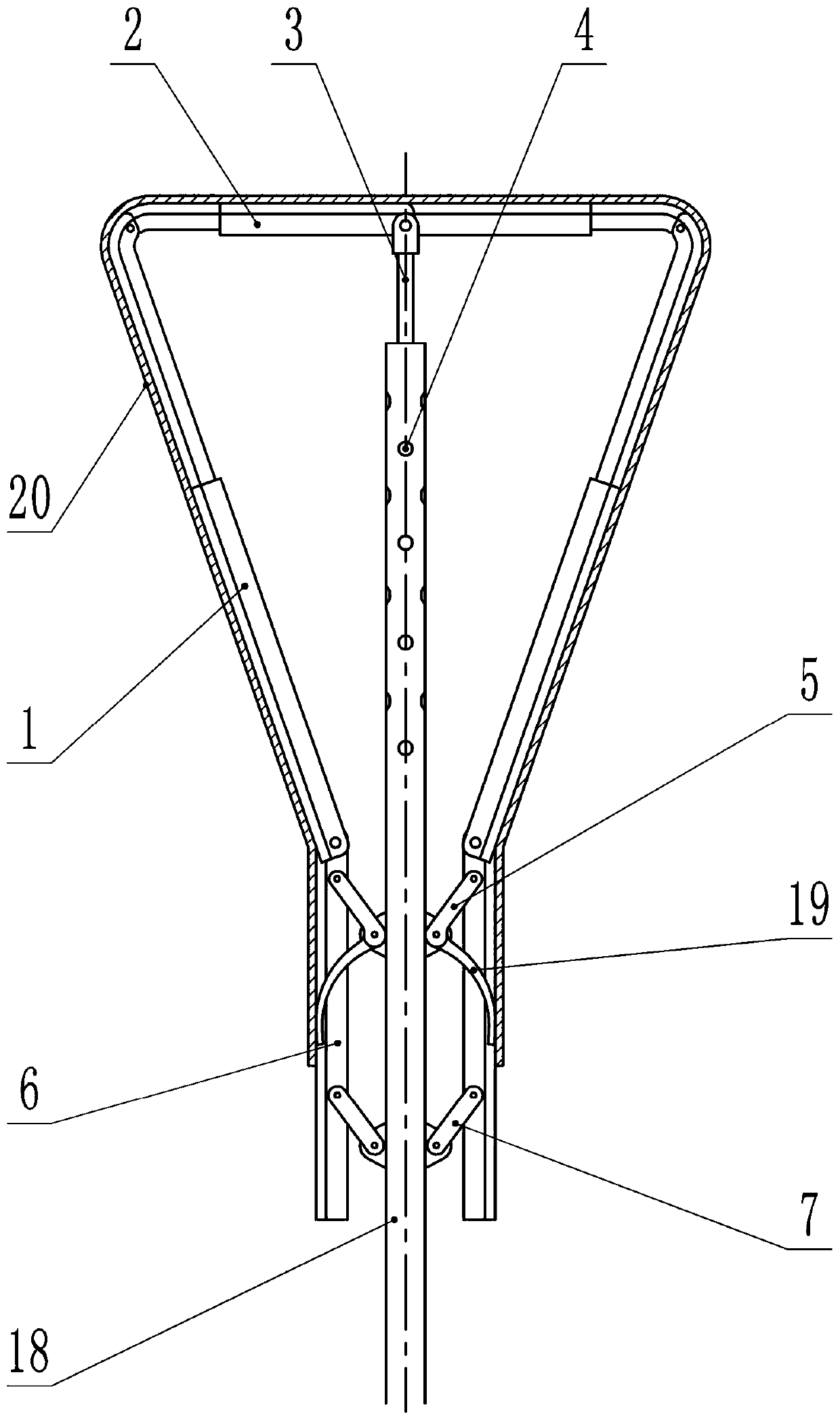

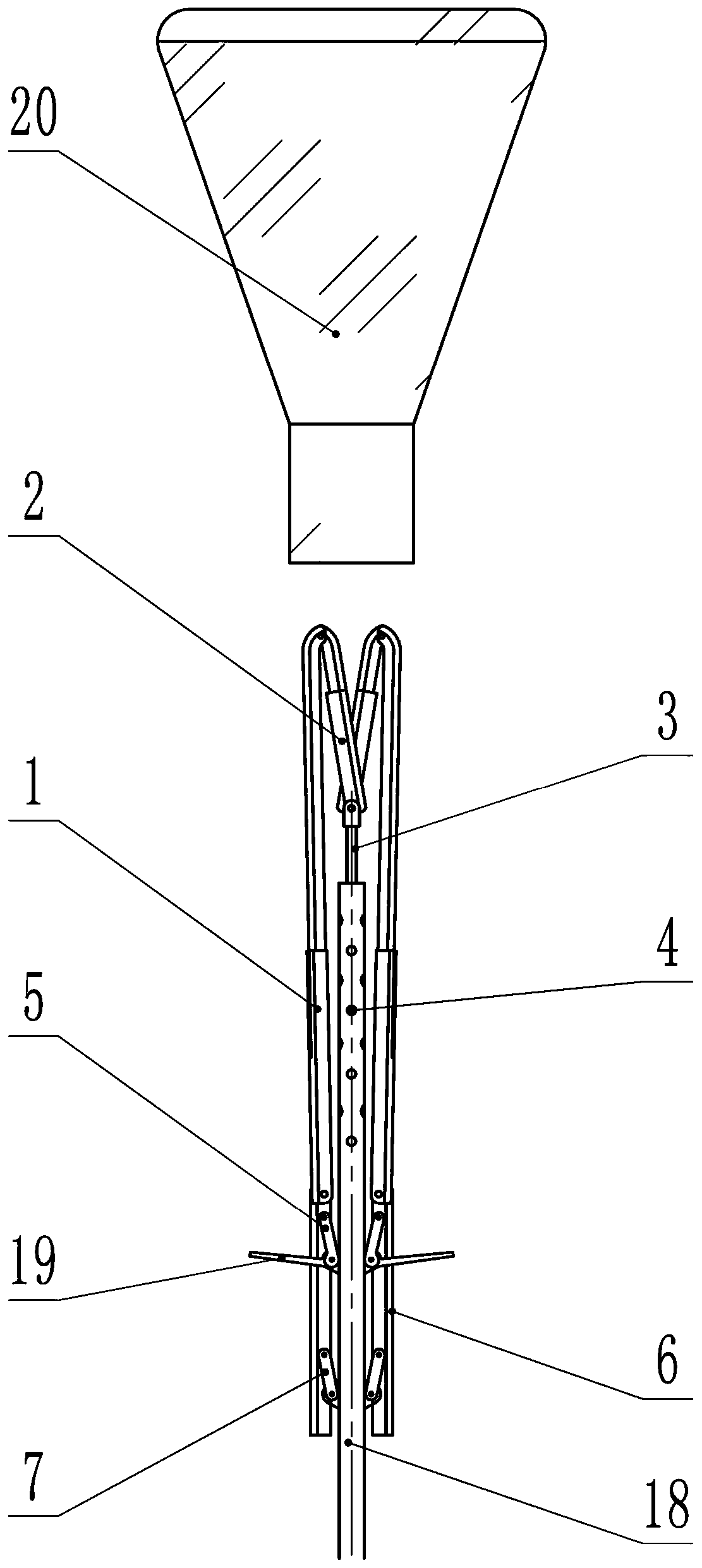

[0021] Such as Figures 1 to 6 As shown, the present invention includes a water basin 10, a motor 16, a cleaning device and water pipes.

[0022] The lower wall of the water basin 10 is provided with a vertical cylinder 11 structure, the structure of the cylinder 11 runs through the lower wall of the water basin 10, the interior of the cylinder 11 runs through up and down, and the structure of the cylinder 11 passes through No. 1 water pipe 18. A bearing 12 and a sealing device 9 are arranged between the No. 1 water pipe 18 and the cylinder body 11 , and the No. 1 water pipe 18 can rotate freely through the action of the bearing 12 ; water leakage from the cylinder body 11 can be prevented through the function of the sealing device 9 . The structural upper end of the cylinder body 11 is higher than the height of the water surface in the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com