Patents

Literature

75results about How to "No dead angle cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

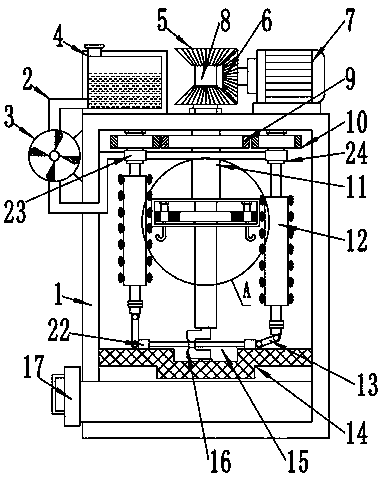

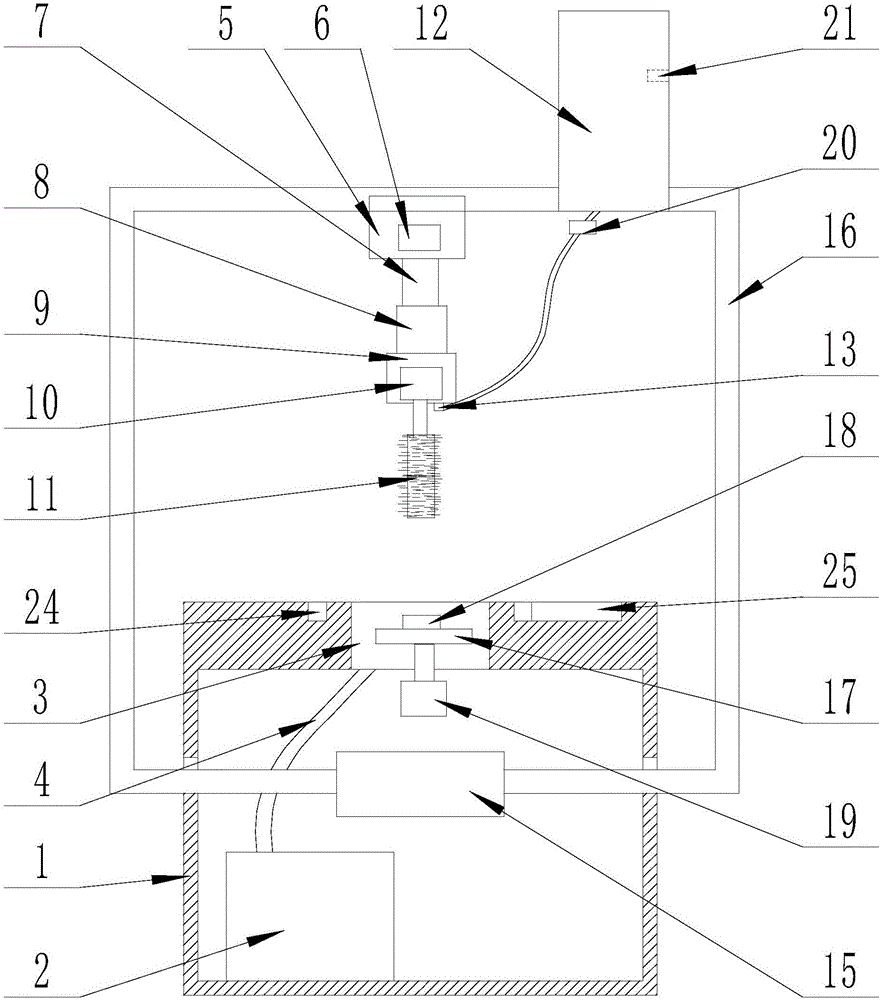

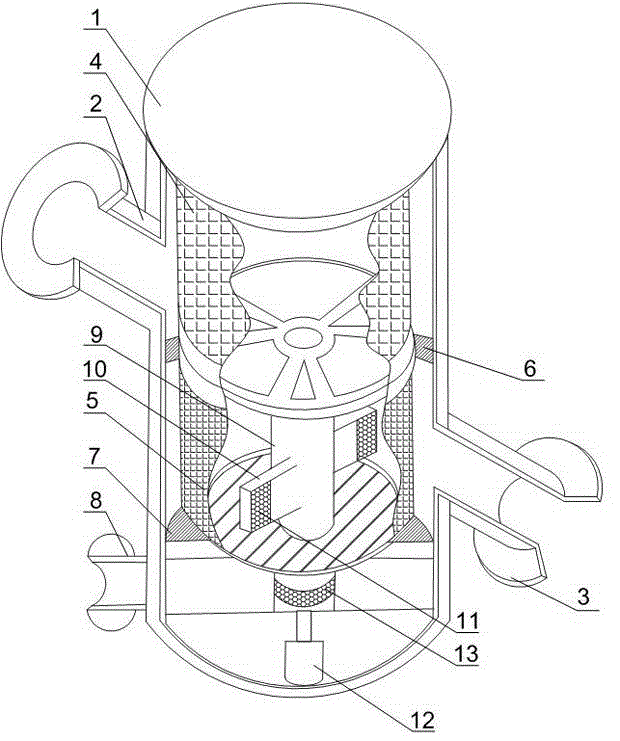

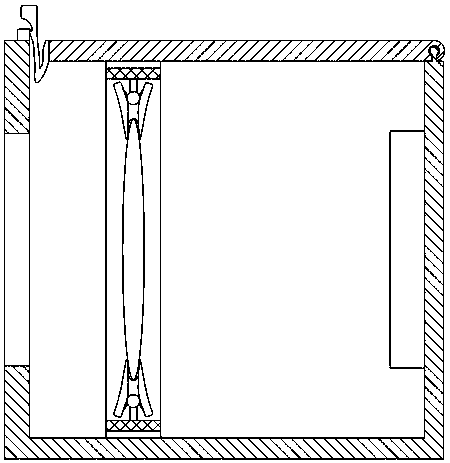

Clinical instrument washing device for digestive system department

ActiveCN107931185ANo dead angle cleaningIncrease contact areaCleaning using toolsCleaning using liquidsRotational axisGear wheel

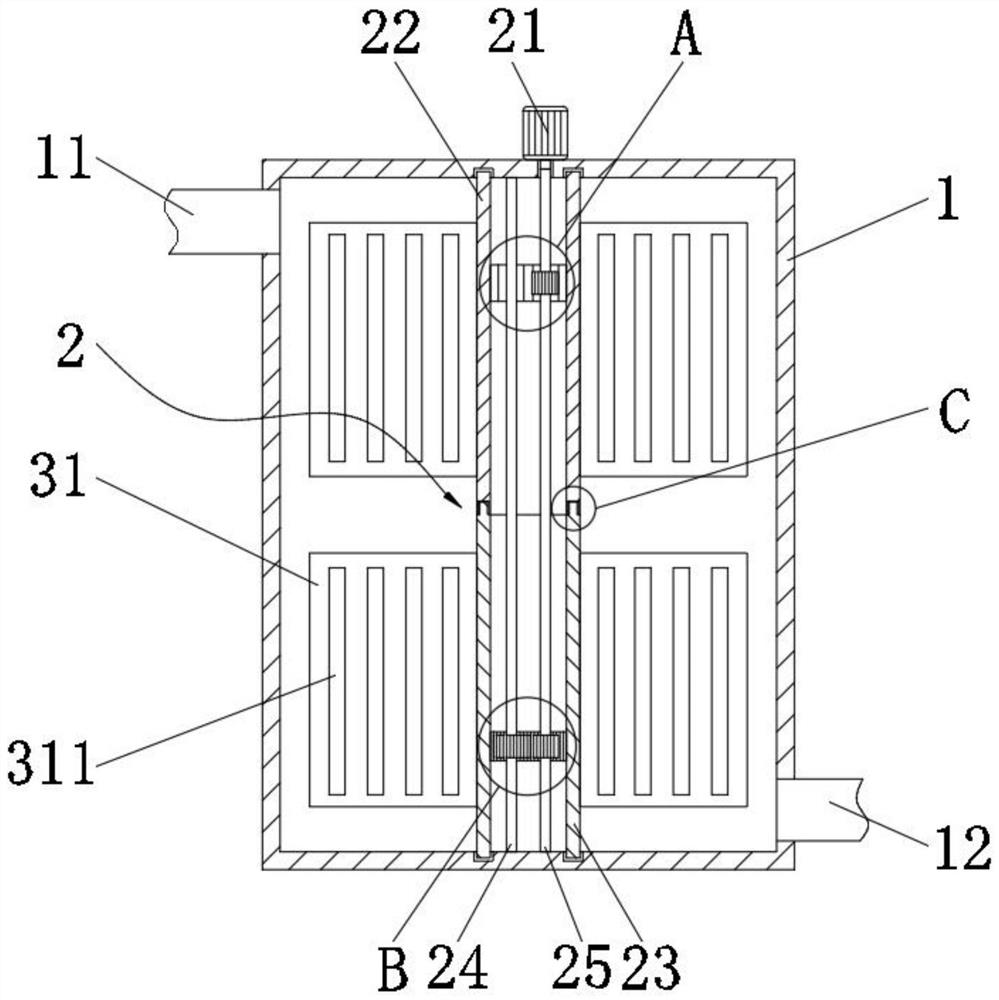

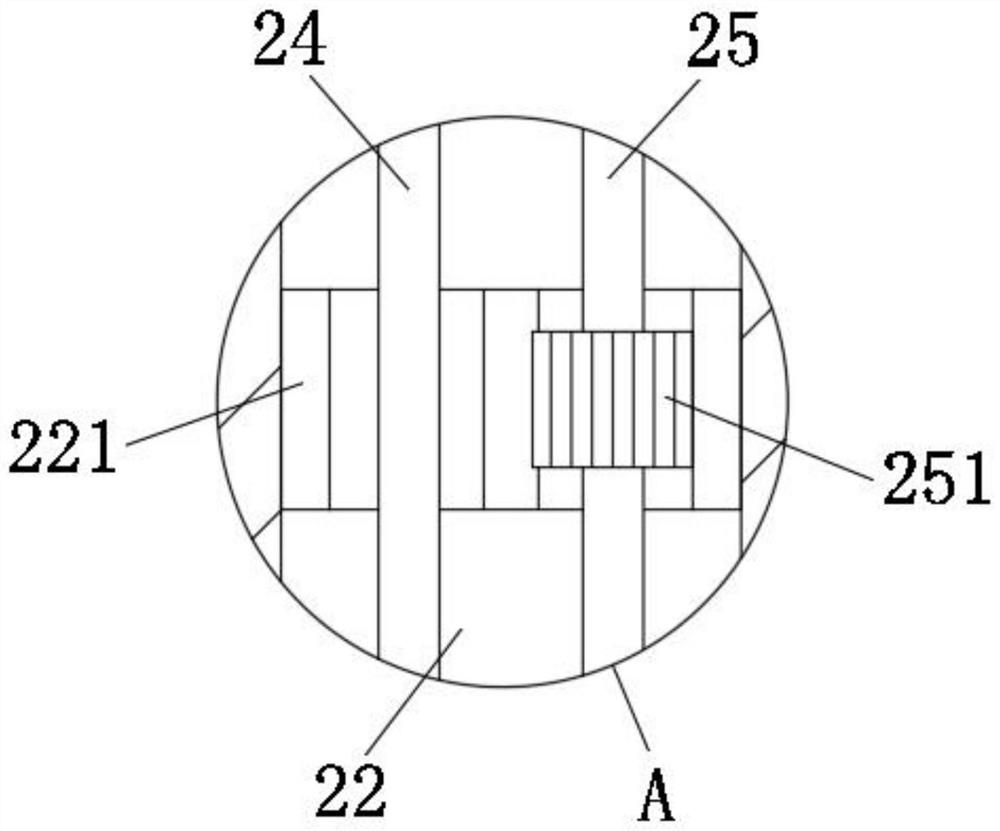

The invention discloses a clinical instrument washing device for a digestive system department. The clinical instrument washing device comprises a washing cavity, a water tank, a motor, a washing roller, a rotary table and a collection groove, wherein the motor is arranged at the upper end of the washing cavity; an output shaft of the motor is fixedly connected with a bevel gear B; bevel gears A are symmetrically arranged at the upper and lower ends of the bevel gear B; the bevel gear A at the upper end is fixedly connected with the upper end of a rotating shaft; the bevel gear A at the lowerend is fixedly connected with a sleeve; the sleeve penetrates through the upper end of the washing cavity and is fixedly connected with the rotary table; a rotary connector is arranged on a rotary shaft at the lower end of the washing roller; the lower end of the rotary shaft is hinged to one end of a connecting rod. The clinical instrument washing device for the digestive system department, disclosed by the invention, is novel in design and simple to operate; a contact area among an instrument, water and the washing roller is enlarged, so that the instrument is scrubbed without dead angles; meanwhile, when the arranged washing roller rotates, the instrument is scrubbed; meanwhile, the instrument is scrubbed in a vertical direction through reciprocating up-down movement; the washing efficiency of the instrument is improved, and the washing effect is increased.

Owner:日照新睿招商发展有限公司

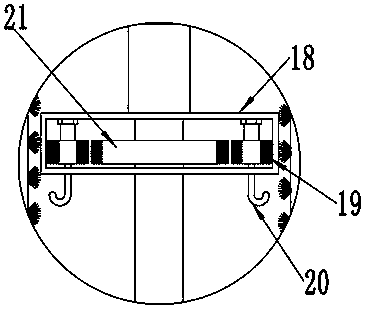

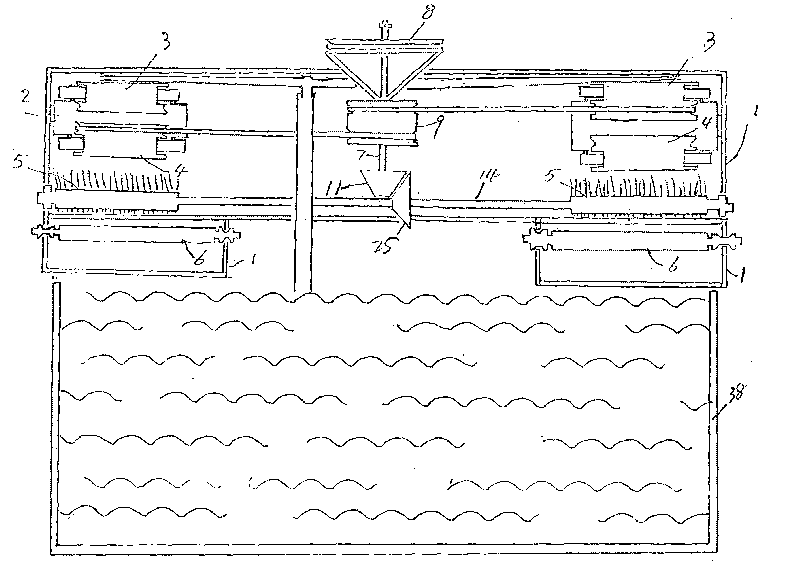

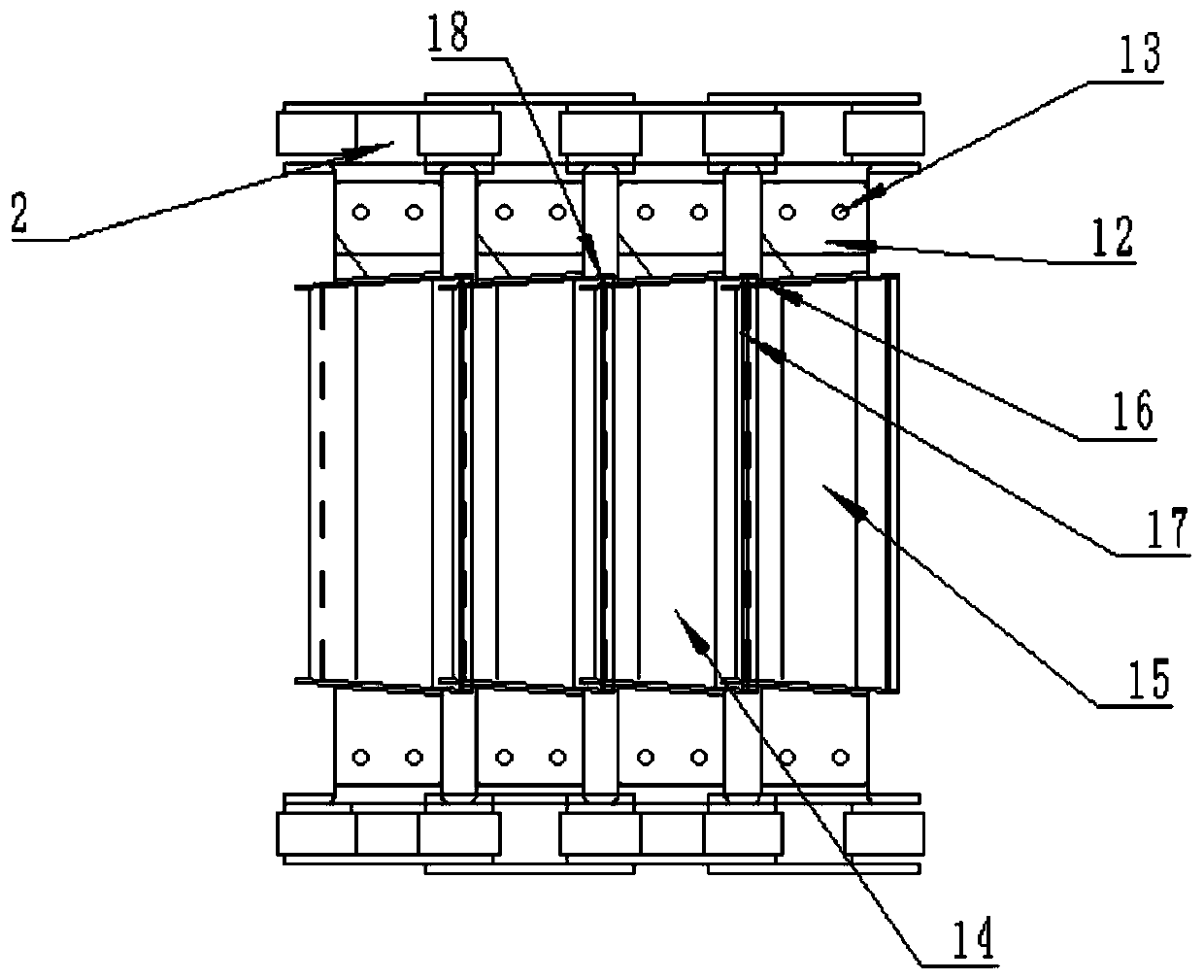

Plate-and-frame filter press

InactiveCN103111106AImprove cleaning efficiencyTightly boundFiltration separationEngineeringMechanical engineering

The invention relates to a plate-and-frame filter press which comprises a support, two cross beams and a hydraulic compressing device arranged on the support, wherein a push plate, a stop plate and a plate-and-frame group are arranged between the two cross beams, one side of each plate frame is in a plane structure, another side of each plate frame is a frame convex, each plate frame has a concave structure inside, one side of each plate frame plane is provided with a plate frame extruding balance beam, a spring and a small hydraulic cylinder are arranged between each plate frame and each plate frame extruding balance beam, a hydraulic oil opening is arranged on a small hydraulic cylinder body, the hydraulic oil opening is connected with a hydraulic oil support pipe, and a hydraulic oil branch pipe on each plate frame is communicated with a hydraulic oil main pipe on each plate frame. The position except a material inlet on the surface at one side of each plate frame is provided with an automatic filter cloth cleaning device. The plate-and-frame filter press is simple in structure, each plate frame can be synchronously pushed in the process of filter-press, the plate frames can be compacted with one another, the material can not be lost, the plate-and-frame filter press is high in filter-press efficiency, the workload of the hydraulic compressing device can be effectively reduced, each plate frame can not deform or be damaged, and the plate-and-frame filter press has a function for cleaning a filter cloth on line.

Owner:王焕坤

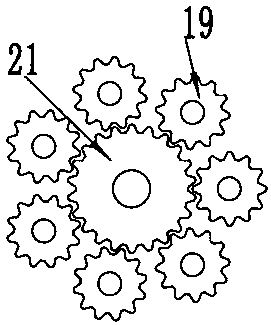

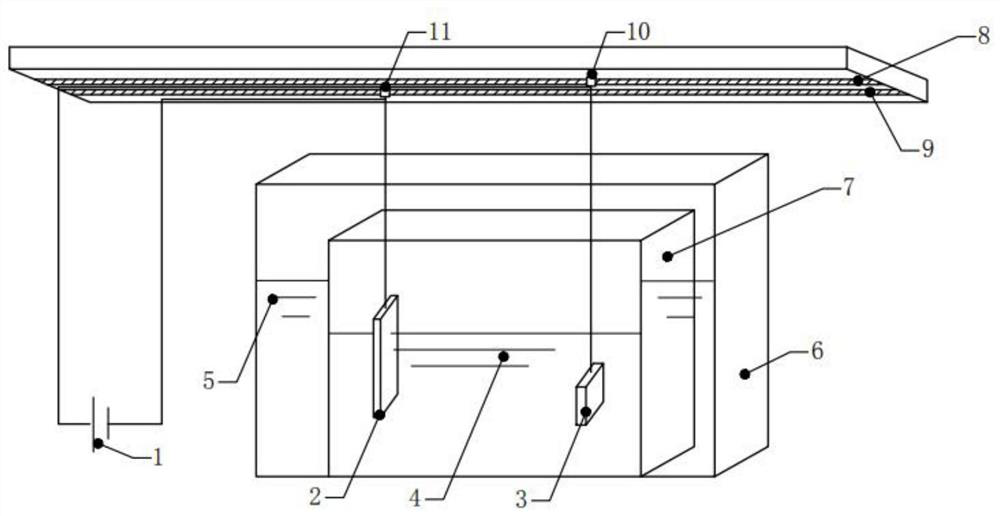

Dust removing cleaning device

ActiveCN106000945ASimple structureEasy to cleanCleaning using toolsCleaning using gasesBristleButt joint

The invention discloses a dust removing cleaning device comprising a workbench. The interior of the workbench is of a cavity structure which is internally provided with a waste liquid recycling barrel. A groove is formed in the workbench and is in butt joint with the waste liquid recycling barrel through a water pipe. A rotating supporting table is arranged in the groove. A dust removing unit is arranged on one side of the rotating supporting table. The workbench is provided with a movable n-shaped frame which is provided with a movement box capable of moving in the length direction of a cross beam of the movable n-shaped frame. A movement box X-phase movement motor is contained in the movement box which is provided with a stand column; a cleaning unit is arranged on the stand column; and a control box is arranged on the workbench and electrically connected with the movable n-shaped frame, the rotating supporting table, the dust removing unit, the movement box X-phase movement motor, a Y-phase driving motor and a bristle rotating motor. The dust removing cleaning device has the beneficial effects of being simple in structure and high in practicability.

Owner:枣庄市恒宇纸业有限公司

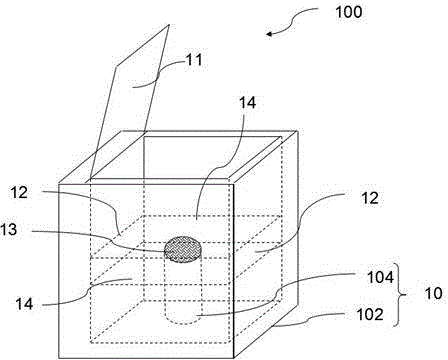

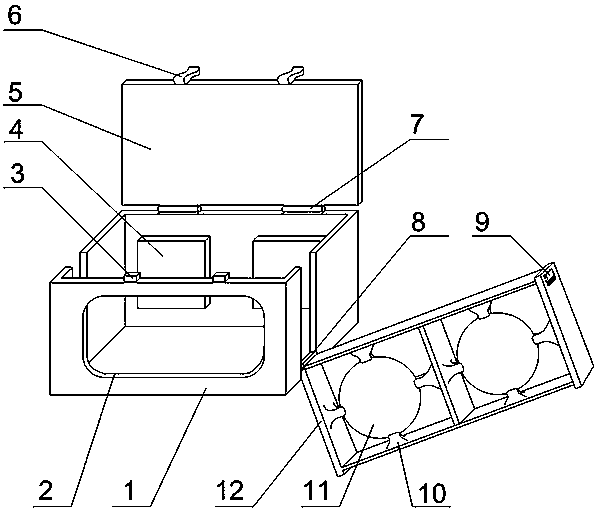

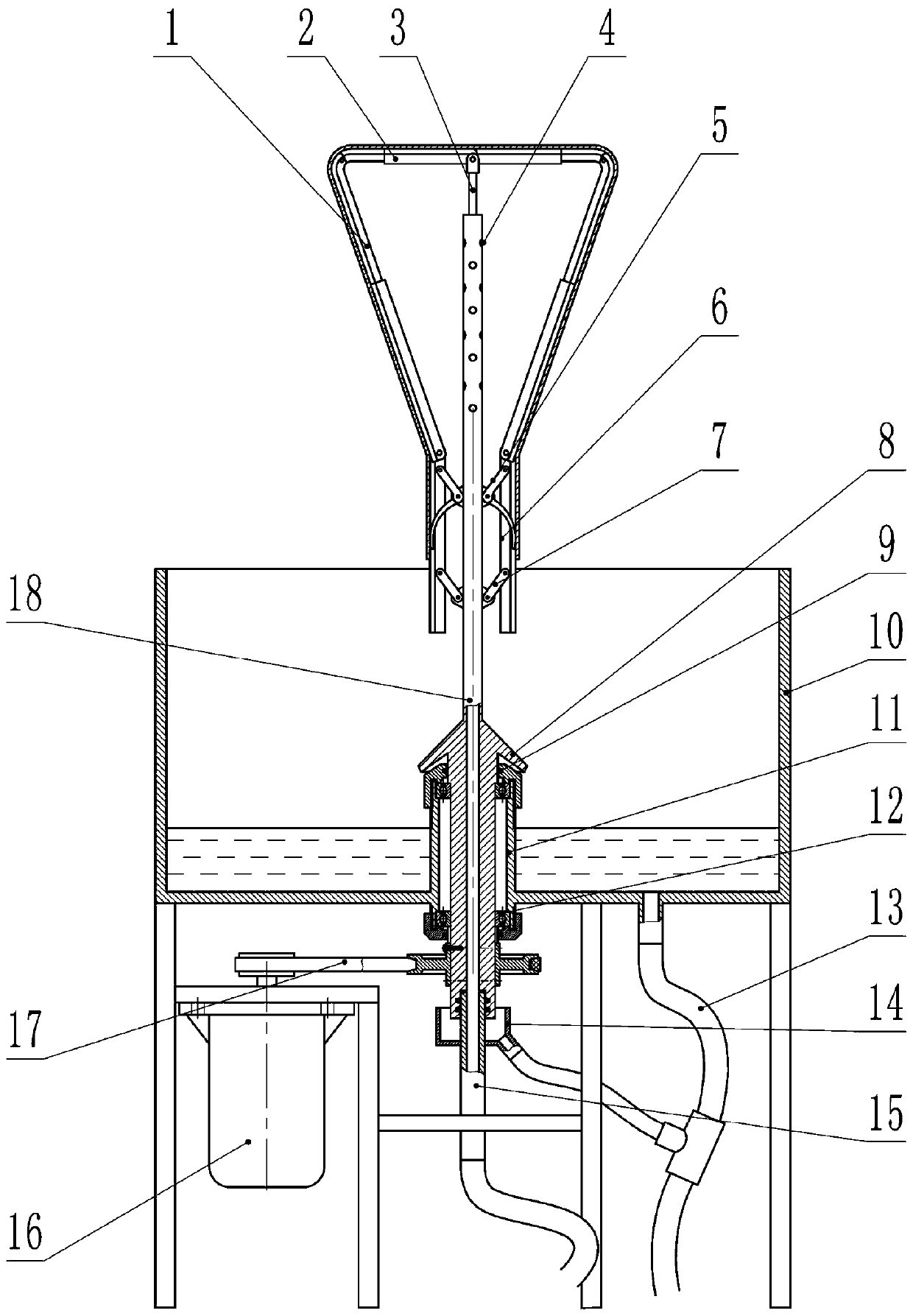

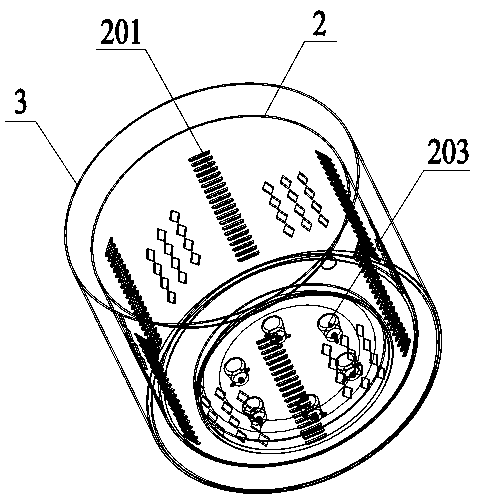

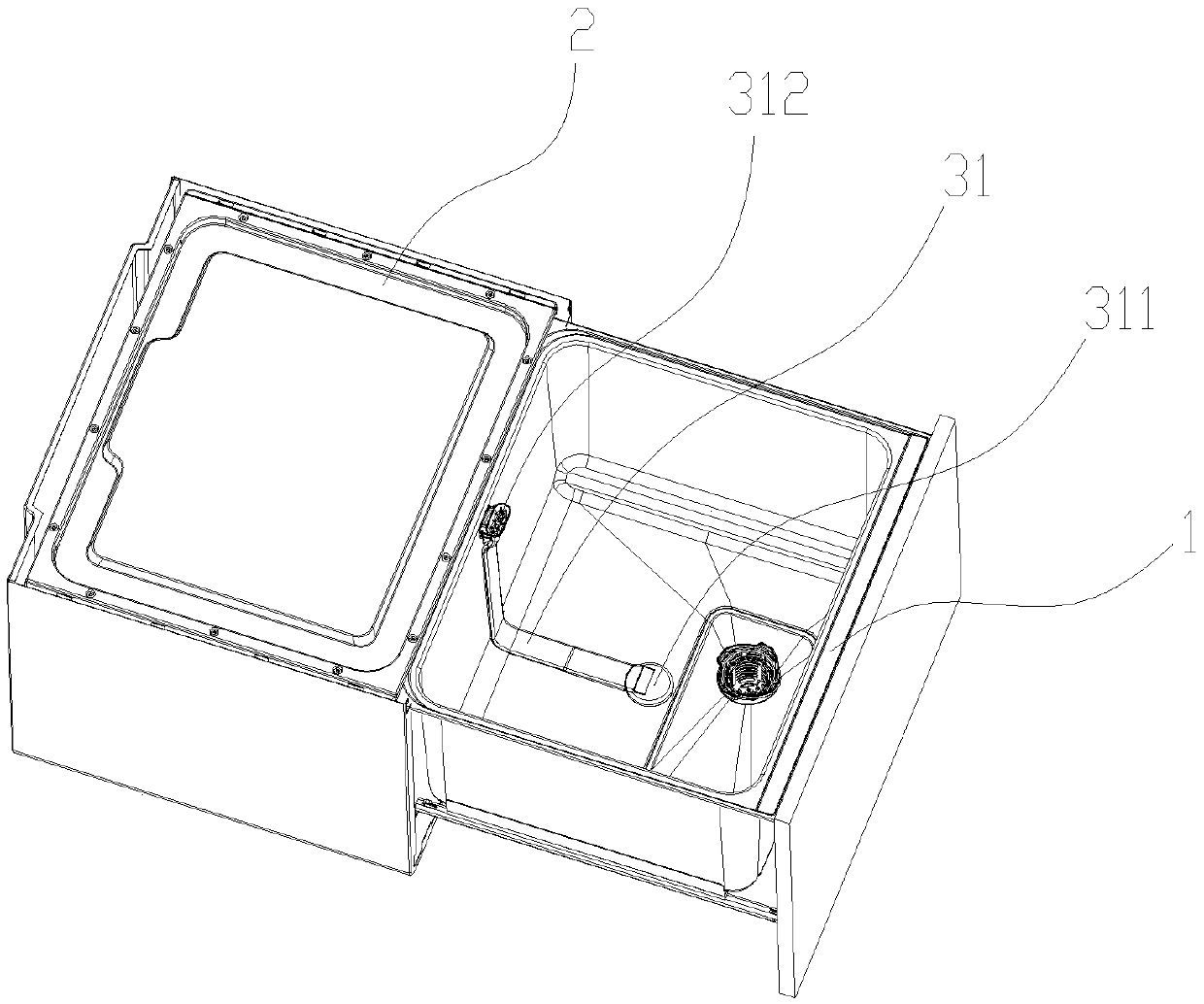

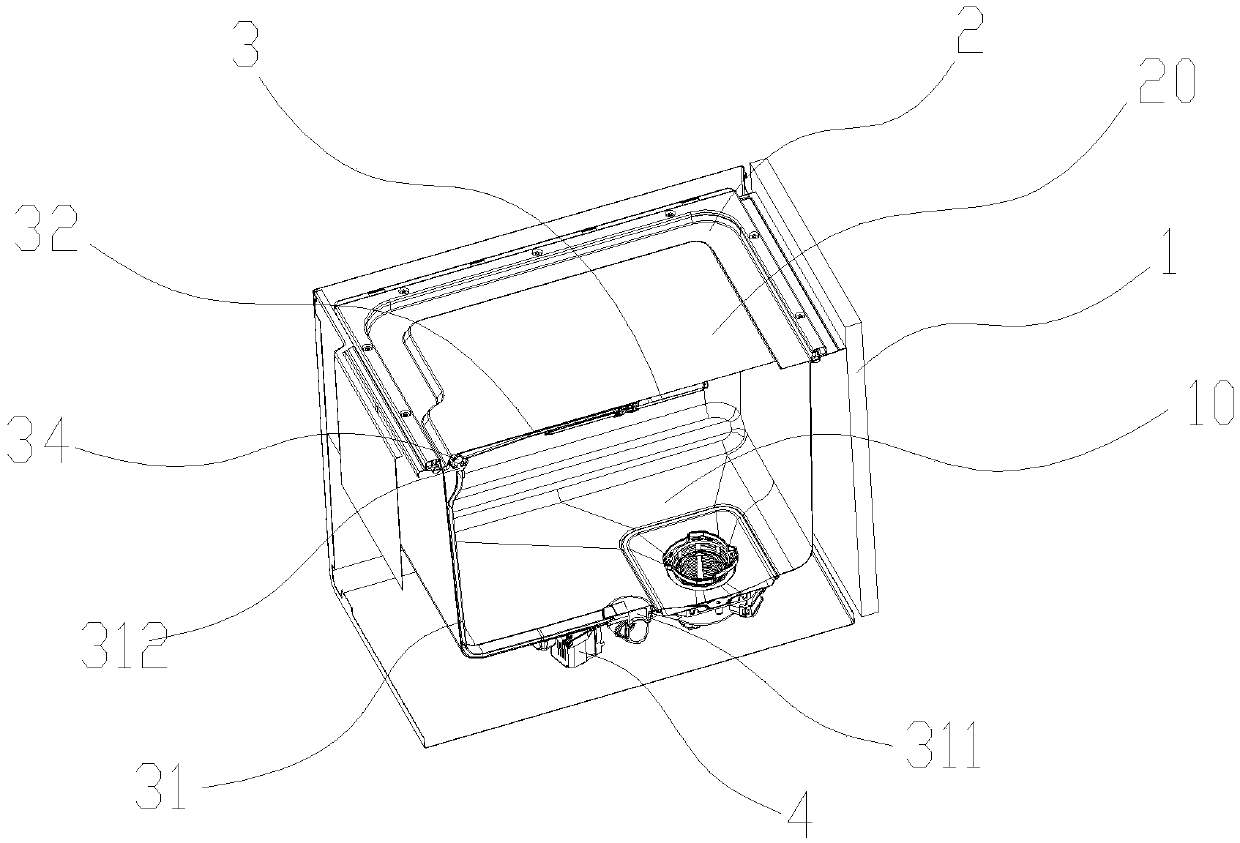

Ultrasonic shoe washing machine

ActiveCN104887166AComprehensive cleaningNo dead angle cleaningFootwear cleanersUltrasonic sensorEngineering

The invention discloses an ultrasonic shoe washing machine. The ultrasonic shoe washing machine comprises a machine body, a cover body, an ultrasonic generating device, a first ultrasonic transduction device and at least one second ultrasonic transducer, wherein the machine body comprises a cavity and at least one cylindrical supporting body arranged on the bottom of the cavity; the least one cylindrical supporting body is used for supporting to-be-cleaned shoes; the cavity is provided with an opening; the cover body is used for sealing the opening; the ultrasonic generating device is used for converting voltage of a power supply into working voltage of the ultrasonic generating device; the first ultrasonic transduction device is arranged on the inner wall of the cavity, electrically connected with the ultrasonic generating device and used for transmitting the ultrasonic waves into the cavity; at least one second ultrasonic transducer is arranged on each cylindrical supporting body, and each second ultrasonic transducer is electrically connected with the ultrasonic generating device and used for generating and transmitting ultrasonic waves into to-be-cleaned shoes.

Owner:福州大学厦门工艺美术学院

Sewage filter of industrial pipeline

InactiveCN104147839AImprove purification efficiencyAvoid cloggingGravity filtersStationary filtering element filtersWaste collectionSewage

The invention discloses a sewage filter of an industrial pipeline. The sewage filter comprises a shell, wherein a water inlet and a water outlet are formed in the shell; a coarse filter core and a fine filter core are arranged in the shell up and down in sequence; a first baffle is arranged at the connection part of the coarse filter core and the fine filter core; the water inlet is formed above the first baffle; a second baffle is arranged at the bottom of the fine filter core; the water outlet is formed between the first and second baffles; the bottom of the coarse filter core is communicated with the fine filter core; a waste collection mechanism is arranged in the fine filter core; a waste exhaust opening is formed in the side of the bottom of the shell; by arranging the coarse filter core and the fine filter core, the sewage can be filtered repeatedly and solid grains of different diameters can be filtered orderly; the purification efficiency of the sewage is improved; the waste collection mechanism can be used for automatically collecting solid grains of small diameters in the fine filter core; and the blockage of the fine filter core is avoided and the labor intensity of manual cleaning is reduced.

Owner:CHENGDU LINGCHUAN CHANGYOU AUTOMOBILE PART MFG

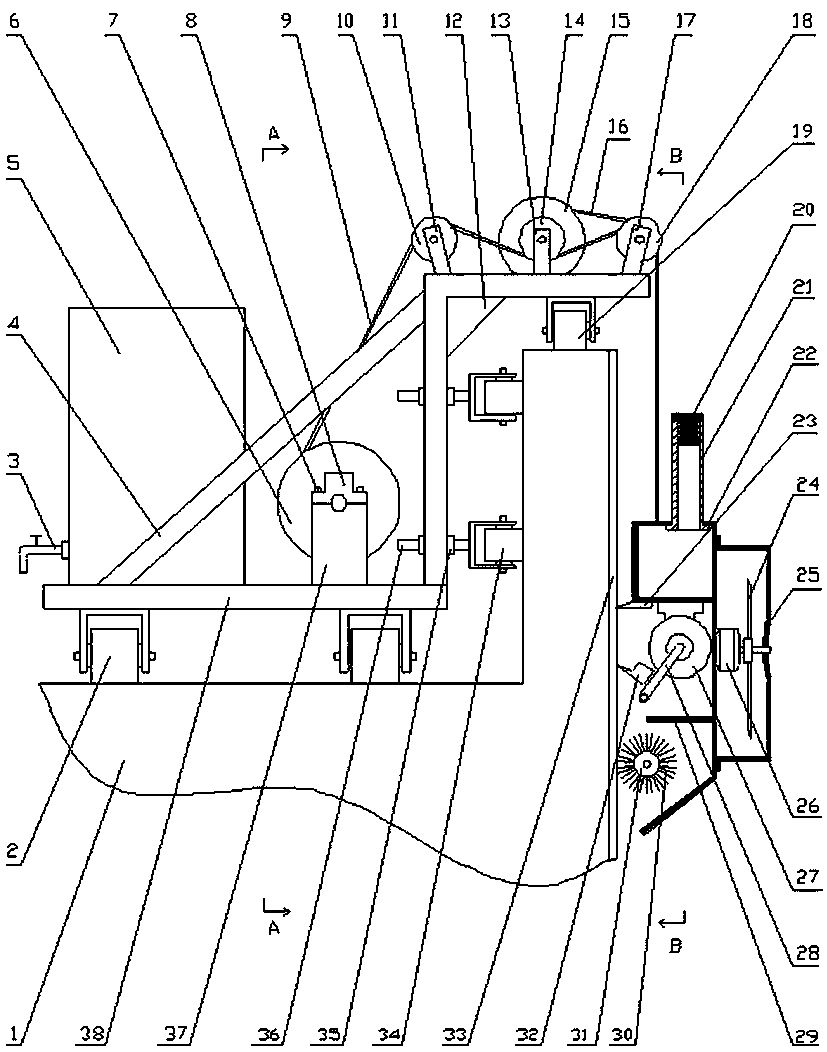

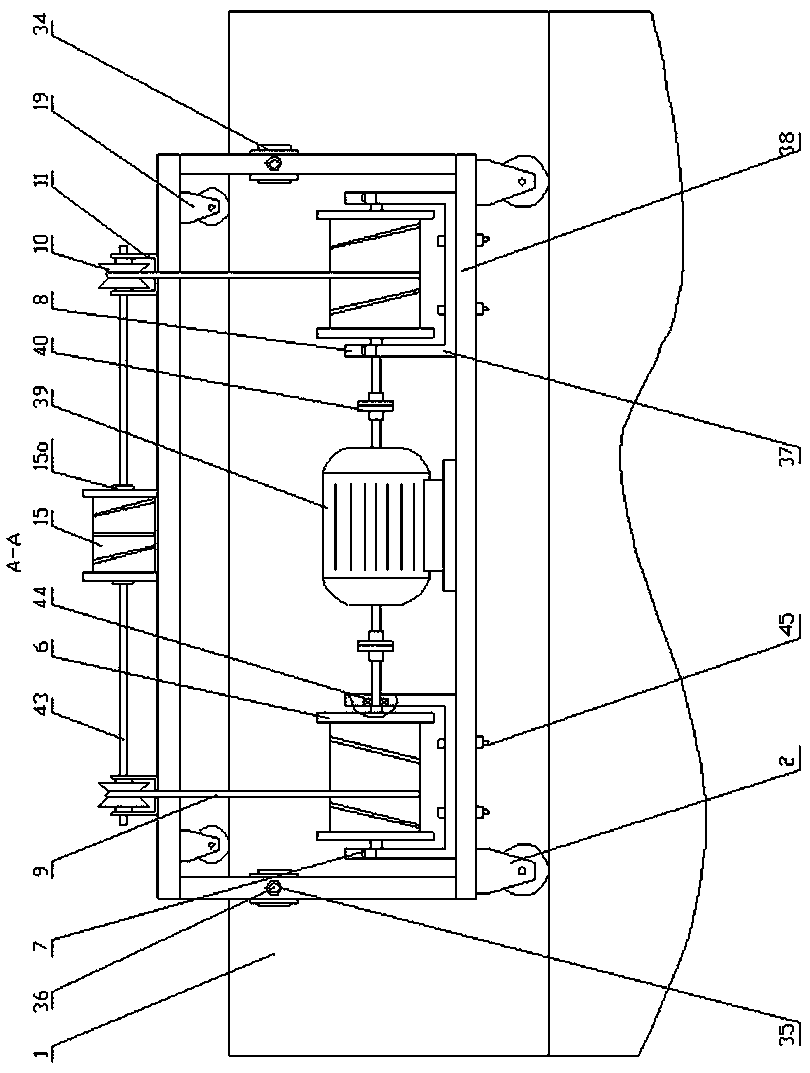

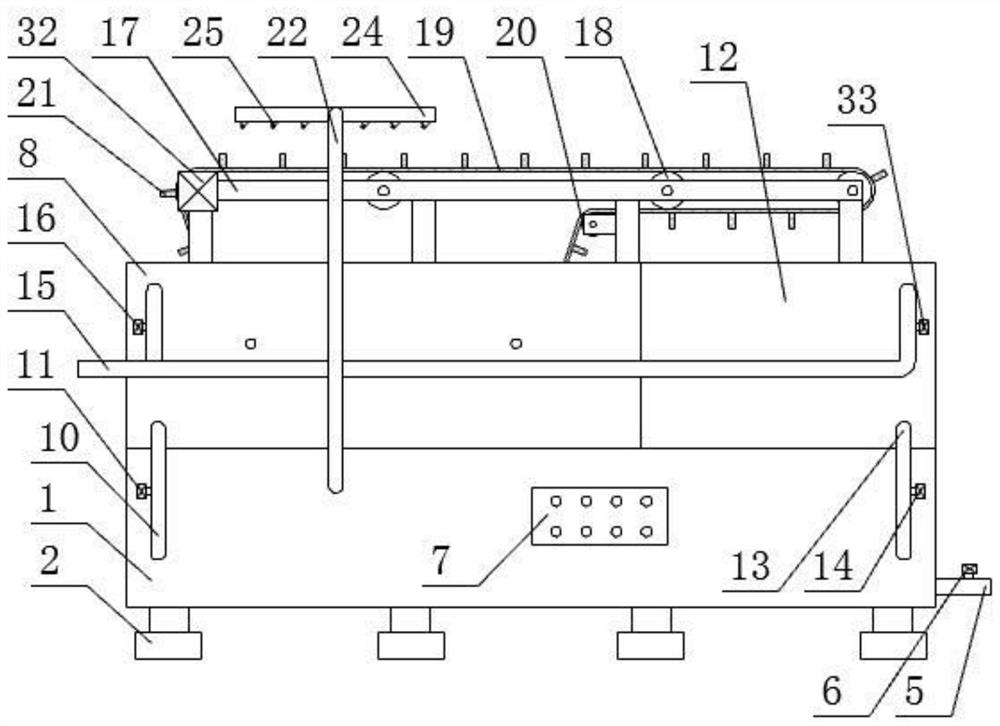

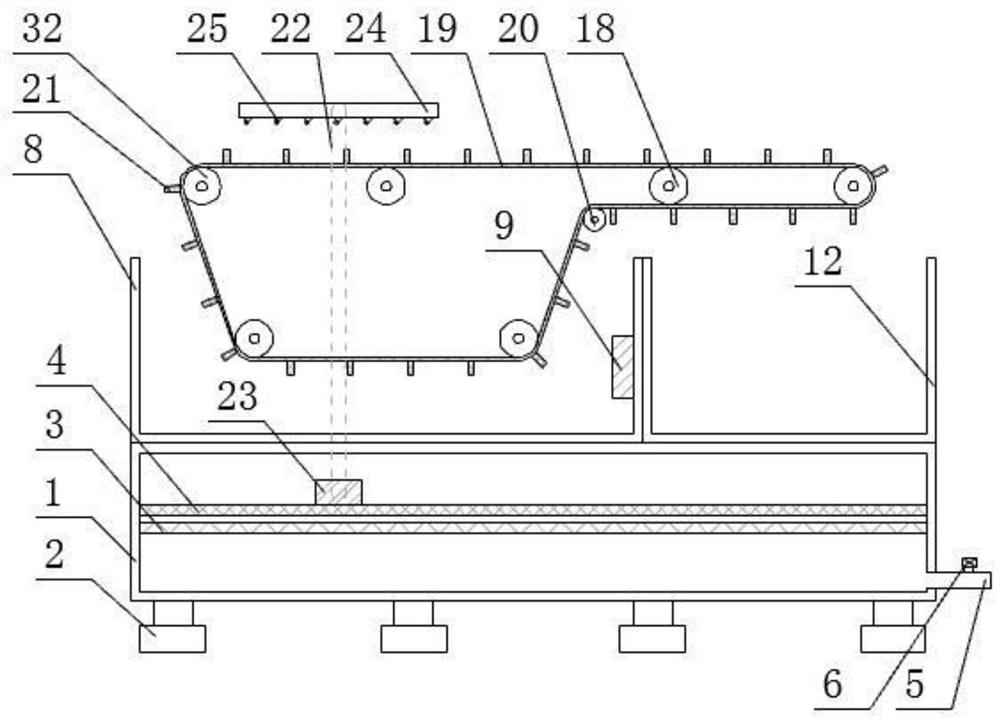

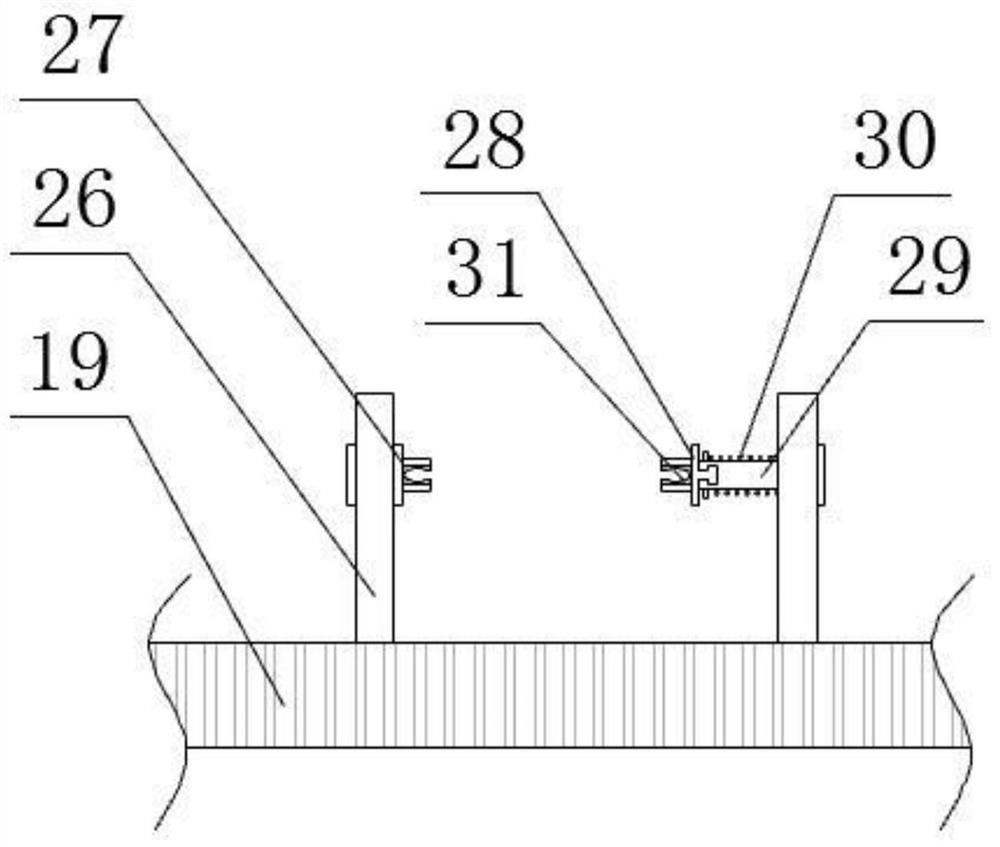

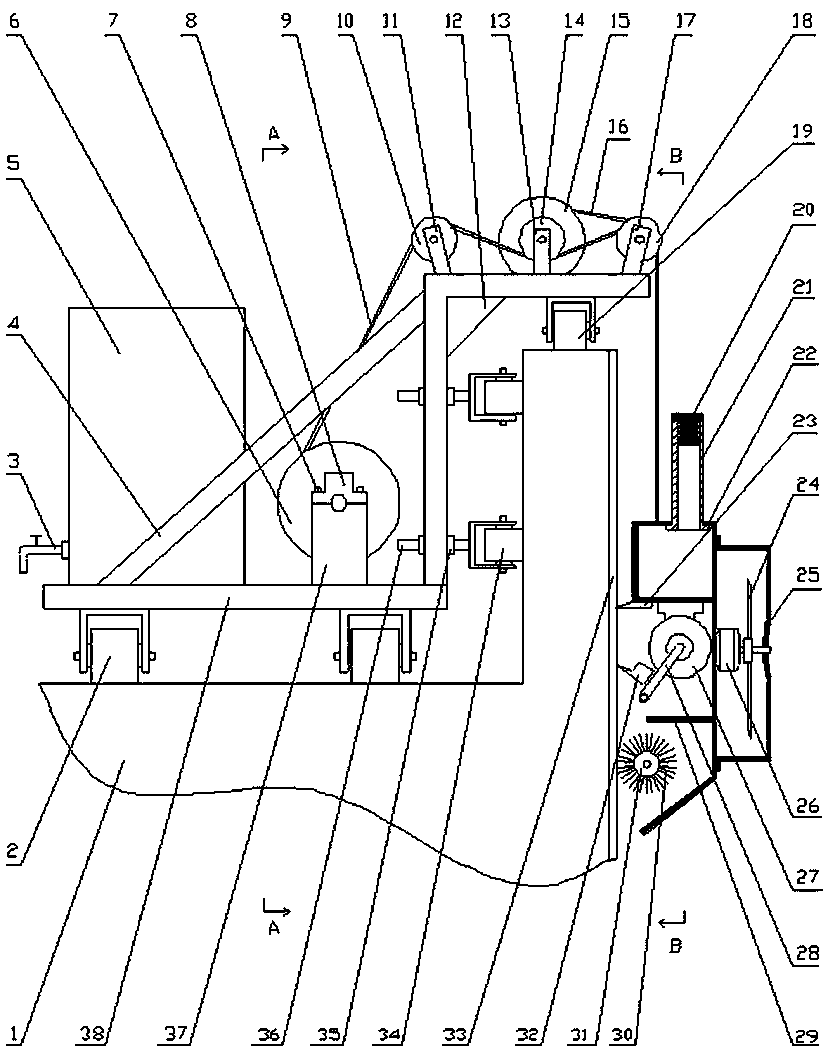

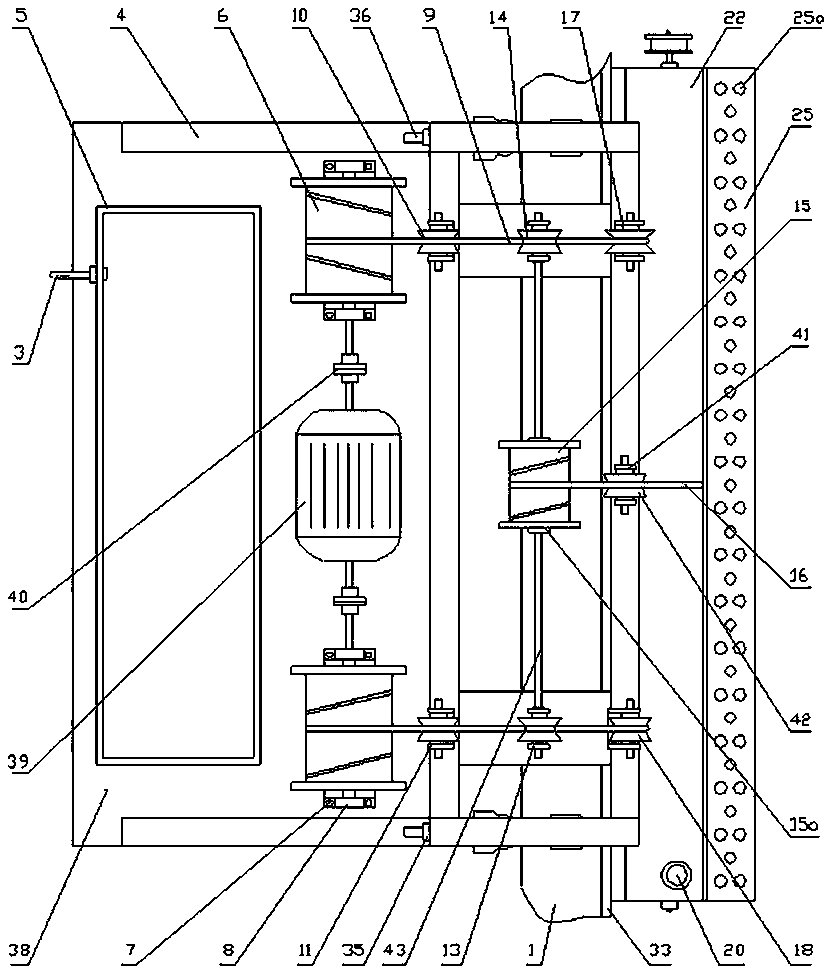

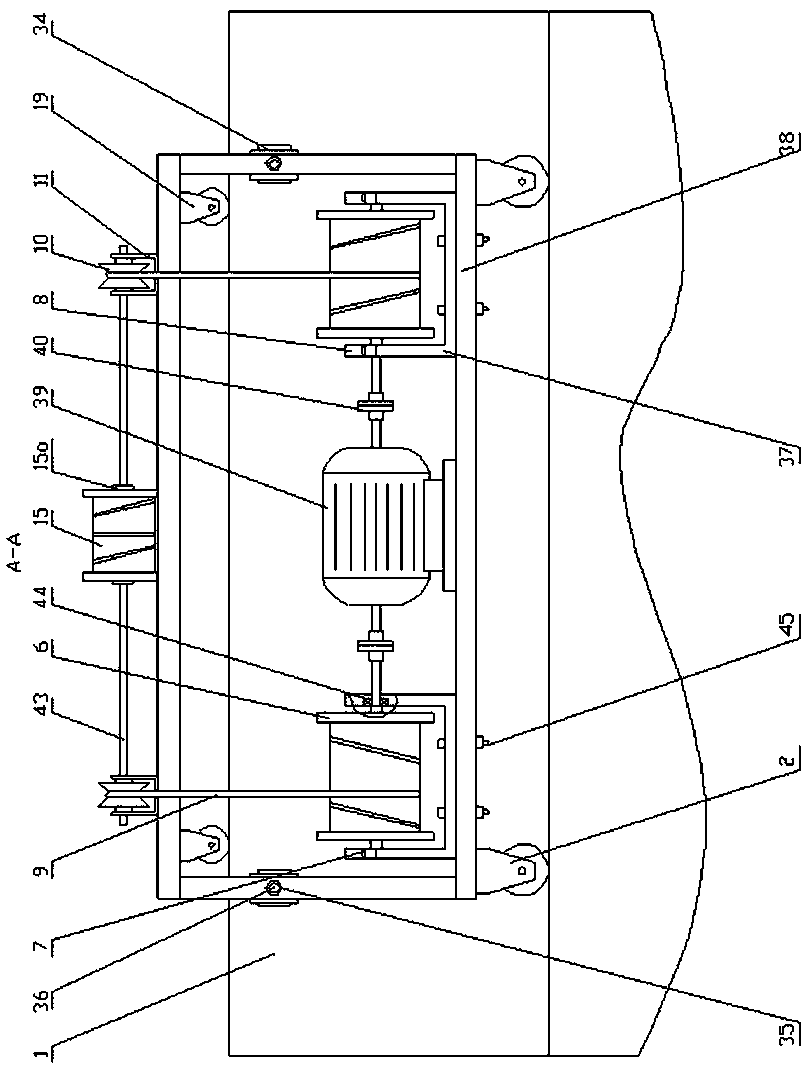

Lateral pressure-type equipment special for cleaning high-rise glass curtain wall

InactiveCN109303515AReduce equipment loadNo dead angle cleaningCarpet cleanersFloor cleanersEngineeringWire rope

Provided is lateral pressure-type equipment special for cleaning a high-rise glass curtain wall. A rack 38 of the equipment is provided with trundles 2, guiding wheels 34, auxiliary wheels 19 and a balance weight water tank 5 and can move stably among the wall body of the glass curtain wall 33. A cleaning box 22 and a wind power box 25 are hoisted through a hoisting motor 39 and a steel wire ropewinding drum 6; the cleaning box 22 is internally provided with a water pump 48, a brush roller 31, a first-level scraping plate 32 and a second-level scraping plate 23, the wind power box 25 is internally provided with a fan motor 26 and a fan 24, and the equipment can tightly fit the surface of the glass curtain wall 33 to achieve rough cleaning and precise cleaning. Electric power is supplied to the cleaning box 22 and the wind power box 25 through a cable winding drum 15 and a cable 16. The cleaning equipment runs stably, supplies electric power and water constantly, conducts cleaning thoroughly without a dead angle and is applicable to cleaning of the high-rise glass curtain wall, and balance weights are flexible and easy to operate.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

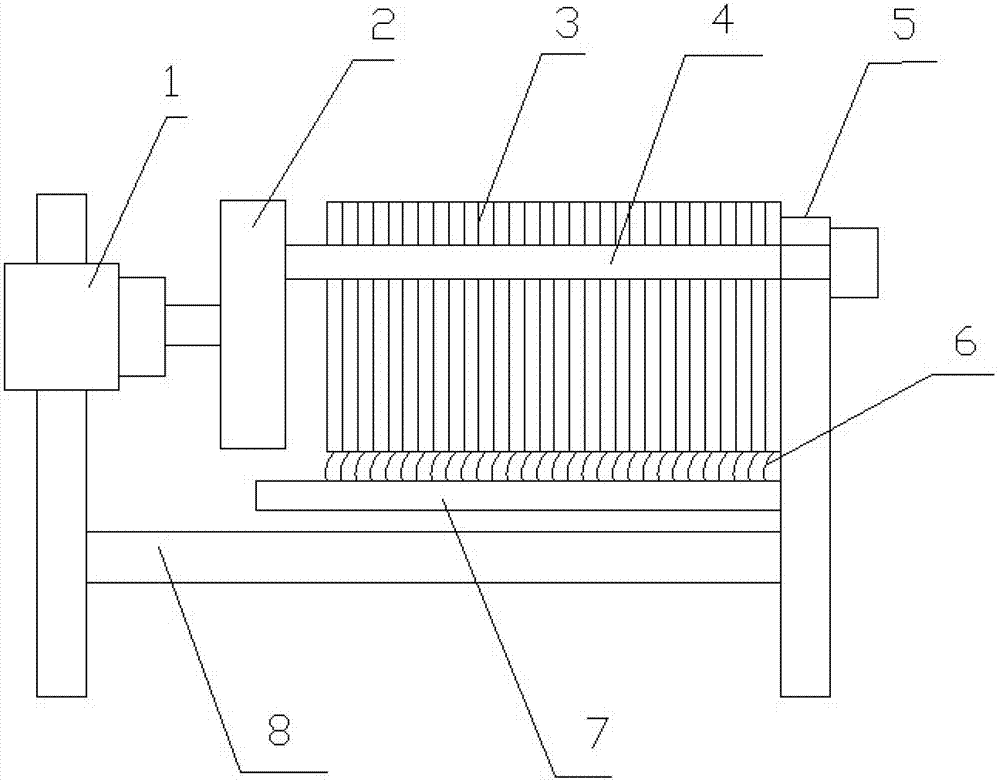

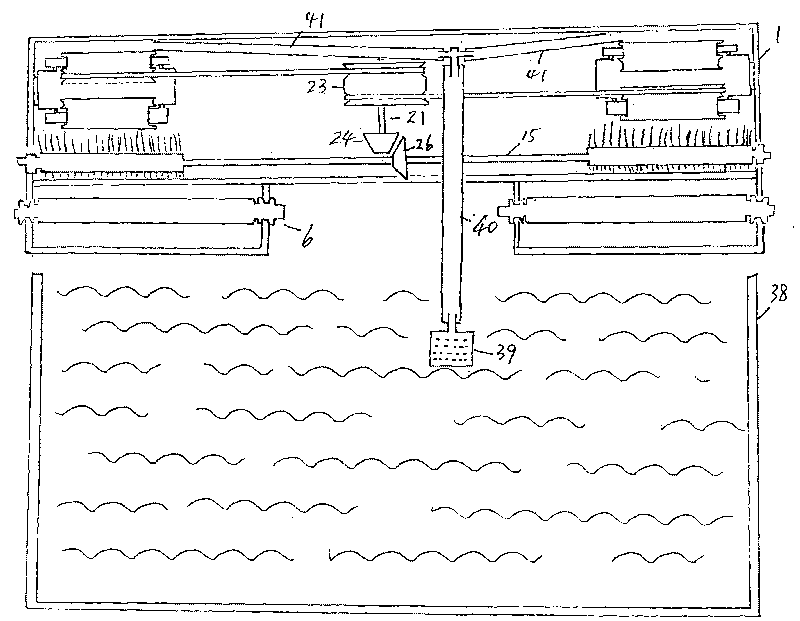

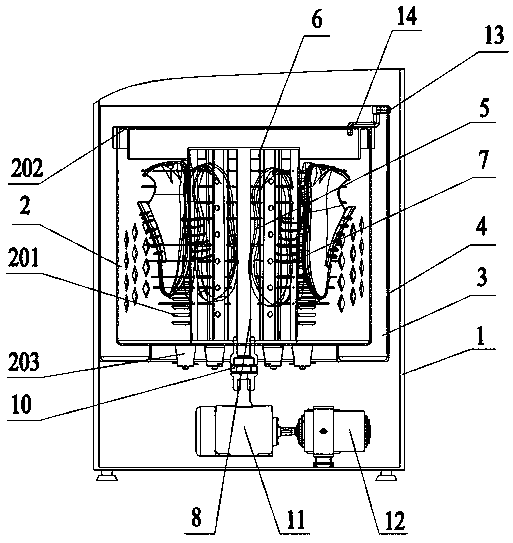

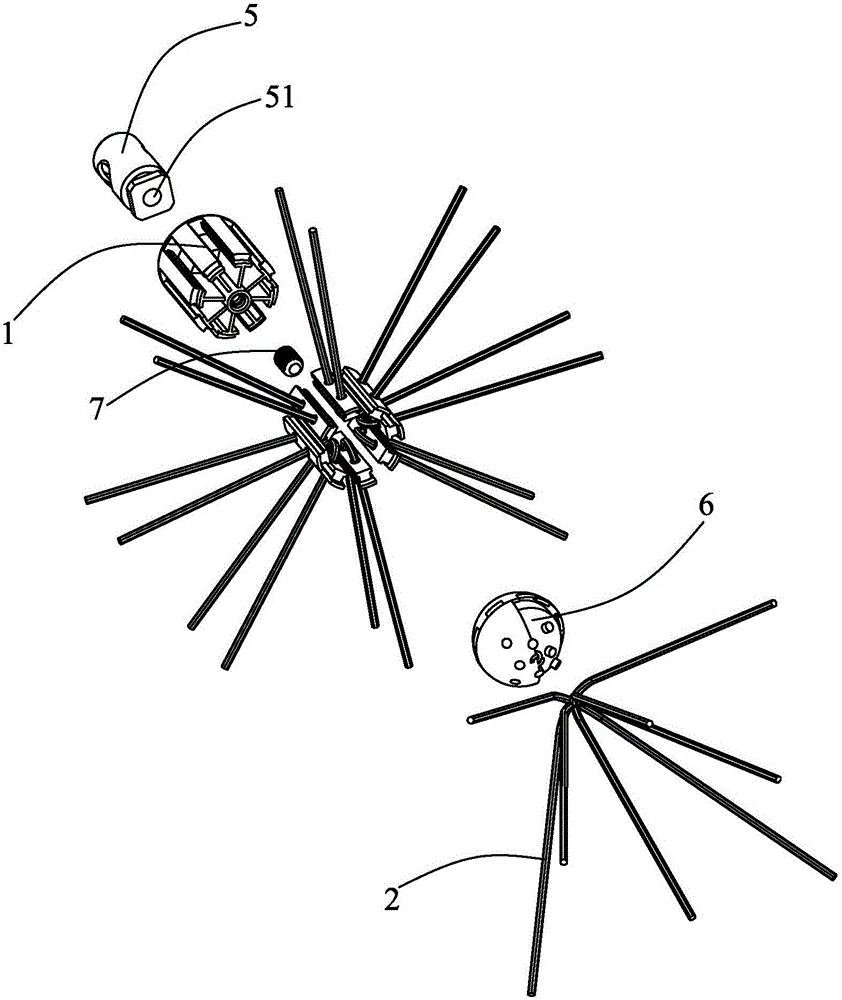

Lotus root washing machine

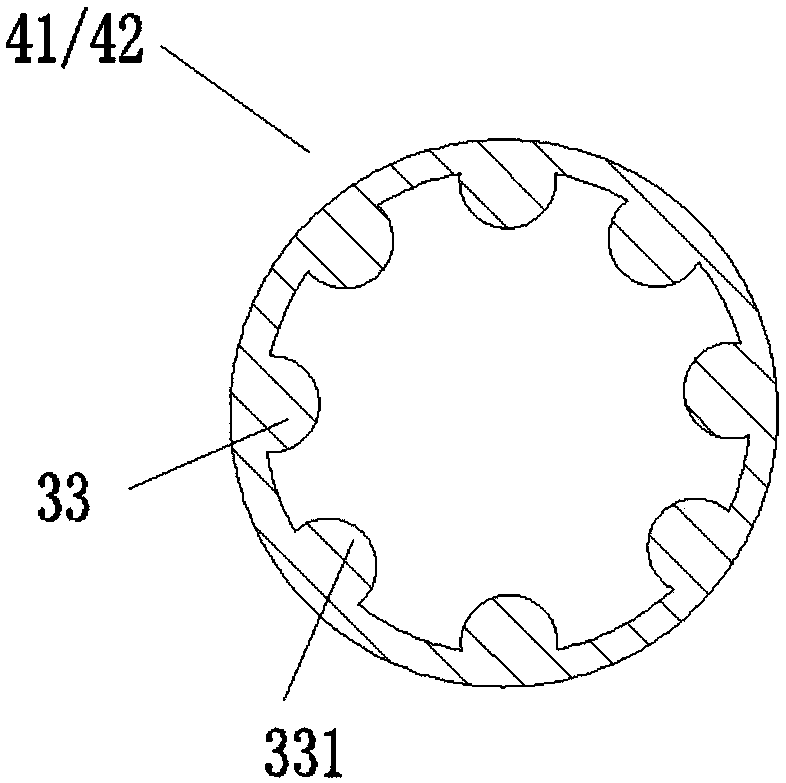

InactiveCN101690606AImprove cleaning efficiencyNo dead angle cleaningFood treatmentMechanical engineeringLotus root

The invention discloses a lotus root washing machine, which solves the problems that the prior lotus root washing machine has incomplete decontamination, low working efficiency and large labor intensity. A stander (1) is provided with a power device, at least one vertical ring (2) is connected with the stander, the vertical ring is in movable fit with an upper inner barrel (3) and a lower inner barrel (4) which are coaxial respectively, a plurality of hairbrushes in the upper and lower inner barrels are connected with an inner barrel wall, the upper and lower inner barrels are in transmission connection with the power device respectively, the upper inner barrel is provided with a lotus root inlet, the lower inner barrel is provided with a lotus root outlet, at least one group of two parallel hairbrushes (5) horizontally arranged under the outlet are in transmission connection with the power device, at least one group of two parallel flexible rolls (6) under the two parallel hairbrushes (5) are connected to the stander through springs, and clearances through which lotus roots pass are formed between each group of two flexible rolls (6) and the two hairbrushes (5).

Owner:文子良

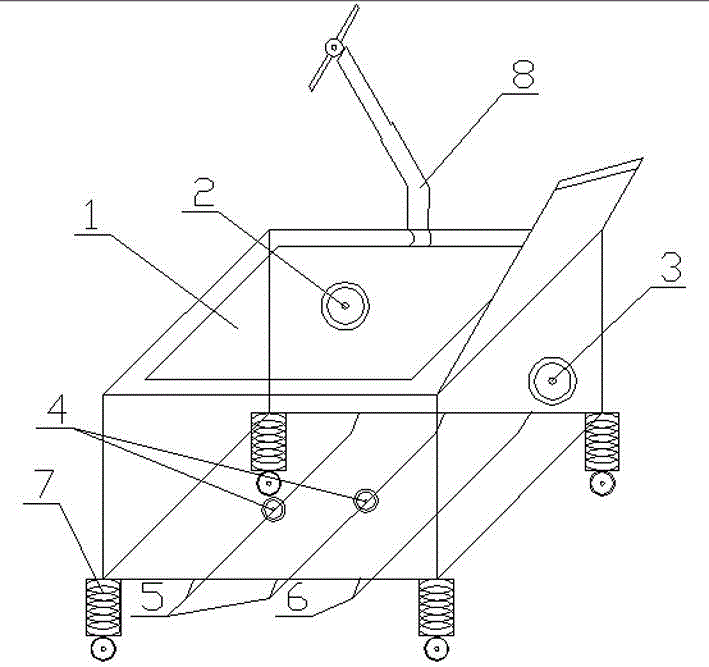

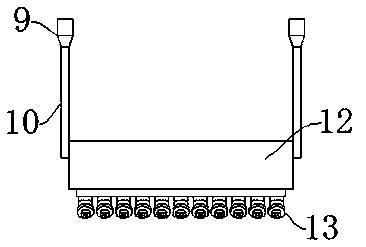

Office mopping and cleaning trolley

InactiveCN105774853AReduce workloadNo dead angle cleaningCarpet cleanersFloor cleanersWater storageUniversal joint

An office mopping and cleaning trolley comprises a trolley plate and a push-pull handrail, and is characterized in that a water storage tank is installed on the trolley plate; the water storage tank is equipped with a water inlet hole, a water drainage hole and two water outlets; the water inlet hole and the water drainage hole are used for water storage and water drainage; the water outlets equipped with water flow controllers are located in the bottom of the water tank; the two water outlets pass through the bottom of the trolley plate and are connected to sponge mopping cloth respectively; an angle of +30 DEG is formed between mopping cloth rods and the vertical water outlets; a piece of dry sponge mopping cloth is connected behind the sponge mopping cloth; spring universal wheel assemblies are installed on four corners located at the bottom of the trolley plate; and a glass cleaning device is connected to one side of the push-pull handrail by a universal joint. When the water storage tank is filled with water, mopping can be carried out for three times simultaneously, wherein cleaning is carried out during the first two times of mopping, and subsequent drying is carried out during the third time of mopping. During the mopping, glass can also be washed, so that cleaning without any dead corner can be realized. The water storage and water drainage can be directly carried out via the water inlet hole and the water drainage hole, so that the water storage tank does not need to be moved. In this way, workloads of cleaning workers are relieved. The trolley can carry out the cleaning in an environment-friendly manner.

Owner:QINGDAO ALLITE AUTO TECHNIC

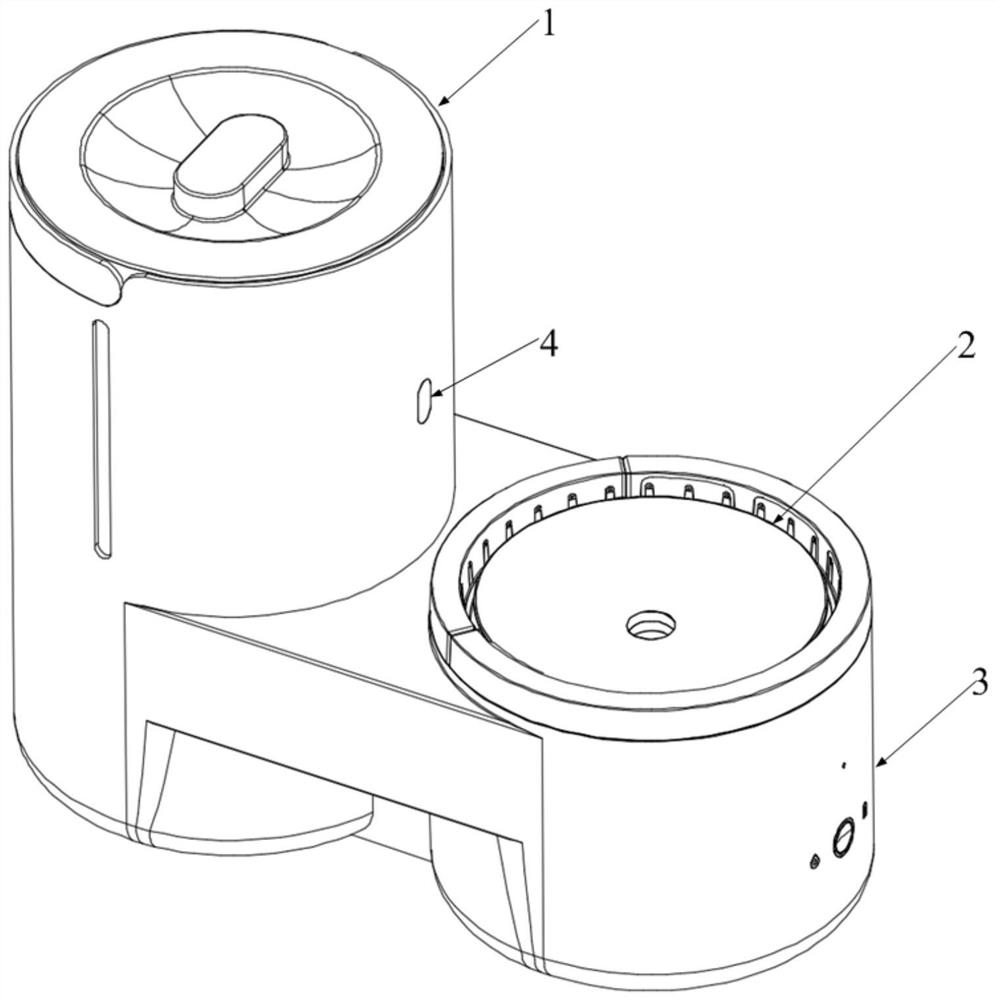

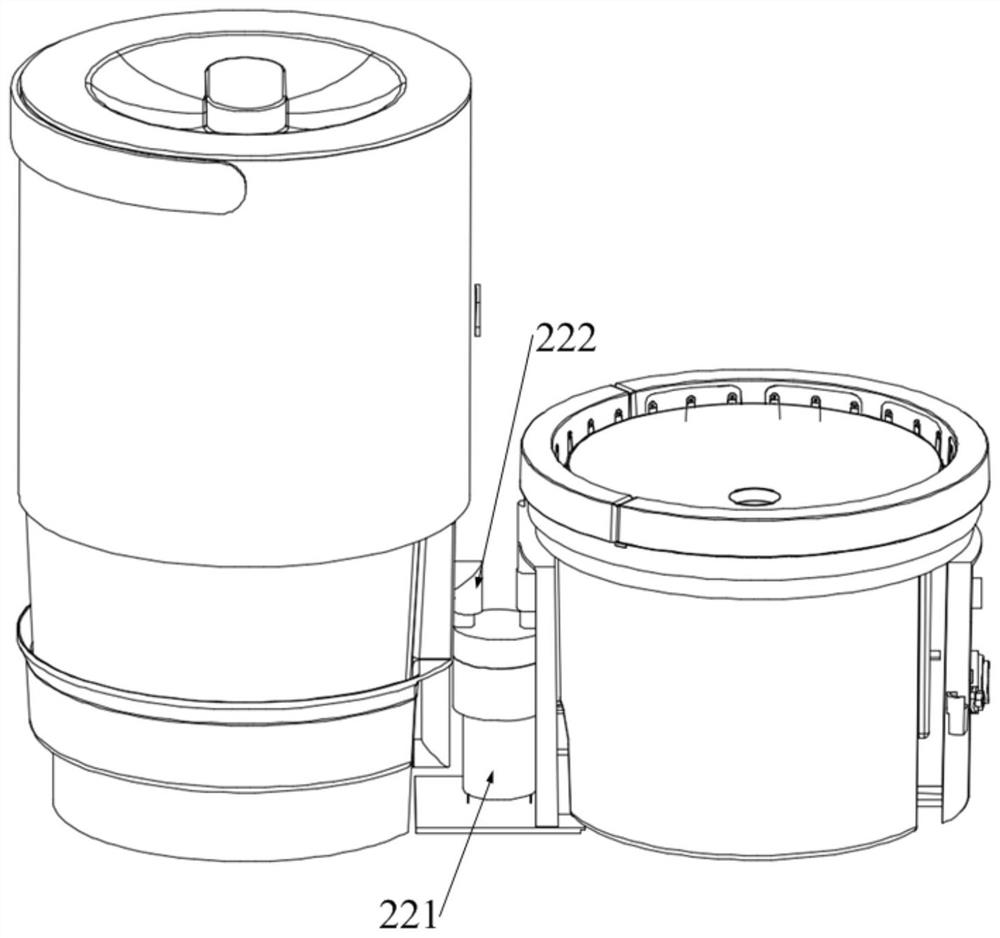

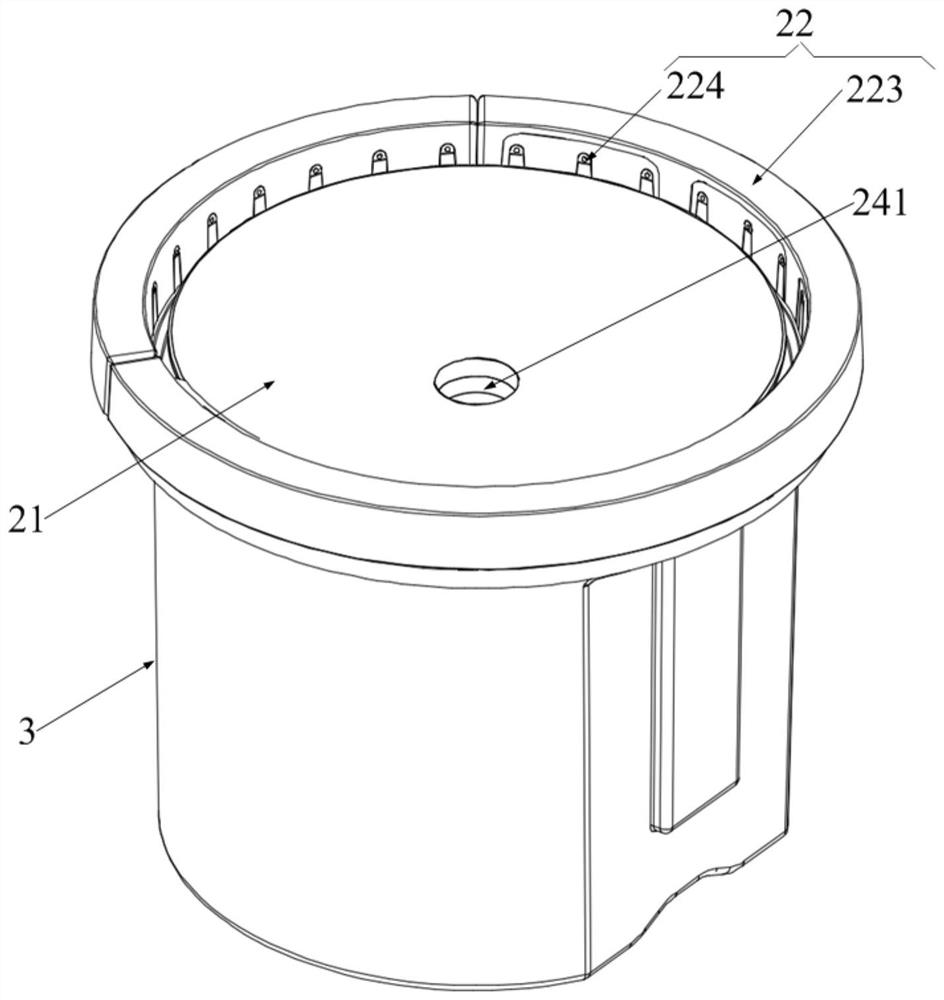

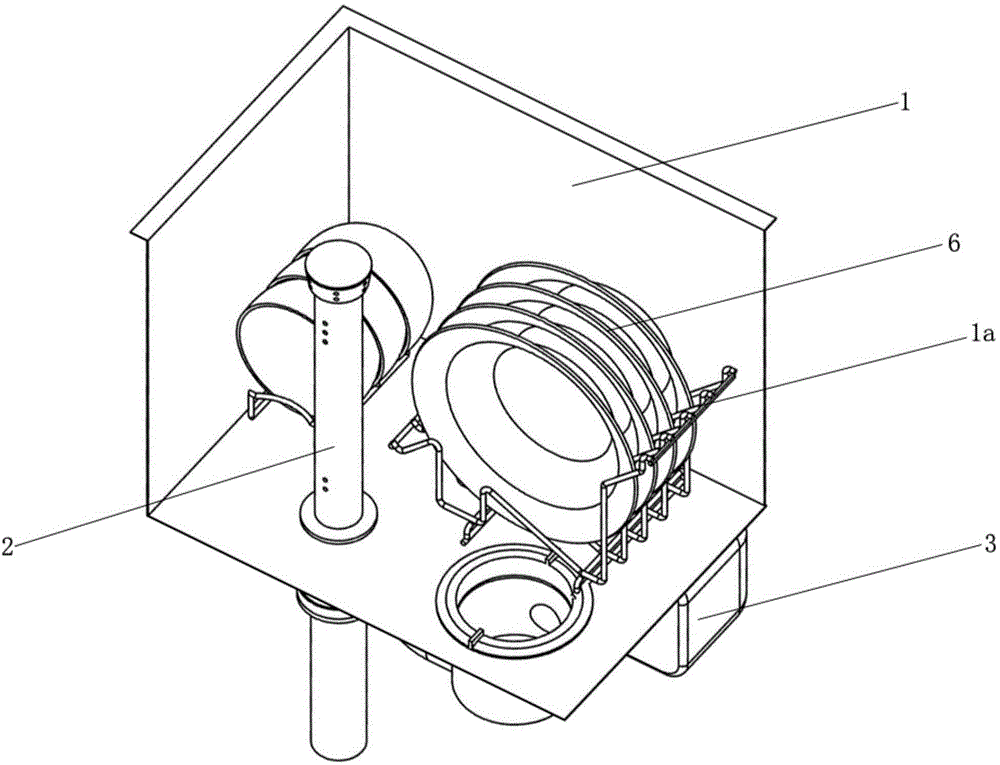

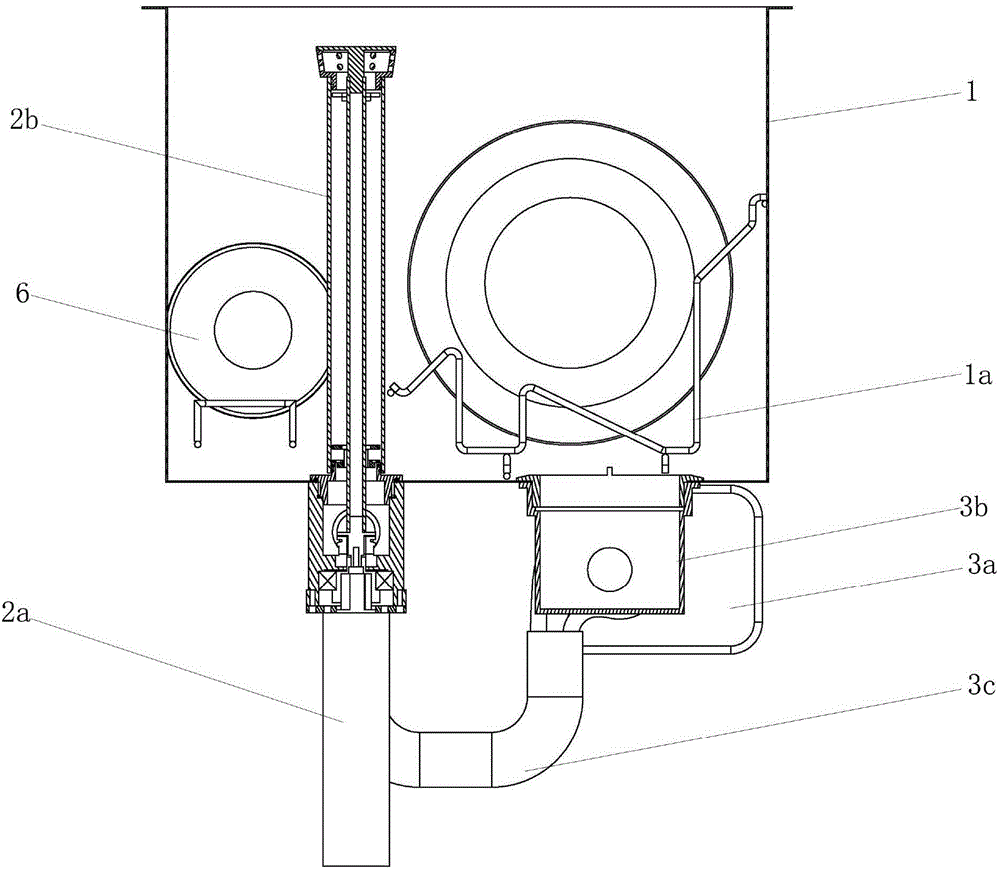

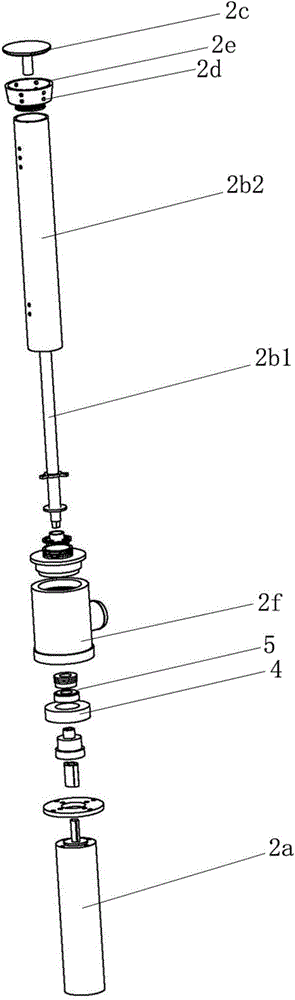

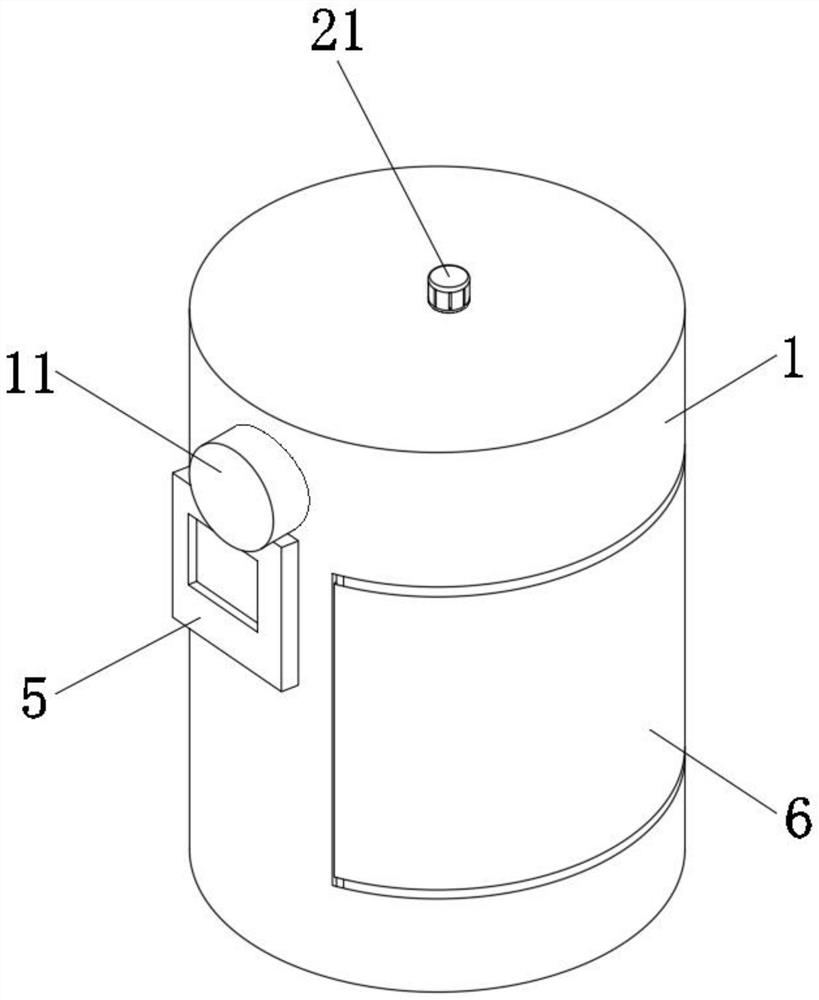

Intelligent water drinking control system and method for pets

PendingCN113455420AAvoid loopsAvoid secondary pollutionAnimal watering devicesControl systemWastewater

The invention discloses an intelligent water drinking control system and method for pets. The control system comprises a water purifying tank mechanism, a drinking water tray mechanism, a waste water tank mechanism, an approaching sensing module and a main control module; the drinking water tray mechanism comprises a drinking water tray, a water inlet mechanism communicating with the water purifying tank mechanism, and a drinking water tray water quantity detection mechanism and a drainage mechanism which are mounted on the drinking water tray; and the water inlet mechanism is used for guiding clean water in the water purifying tank mechanism to the drinking water tray for the pets to drink water, and the water inlet mechanism can also be used for cleaning the surface of the drinking tray. By adopting the design that a water purifying tank and a waste water tank are separated, water circulation can be avoided, secondary pollution of water flow is prevented, then the health of pets is not affected, meanwhile, the water drinking amount of the pets can be accurately detected, the functions of automatically supplementing water, changing water, cleaning, draining water and the like can be achieved, and the health of the pets can be further guaranteed.

Owner:SHENZHEN CHEERBLE TECH CO LTD

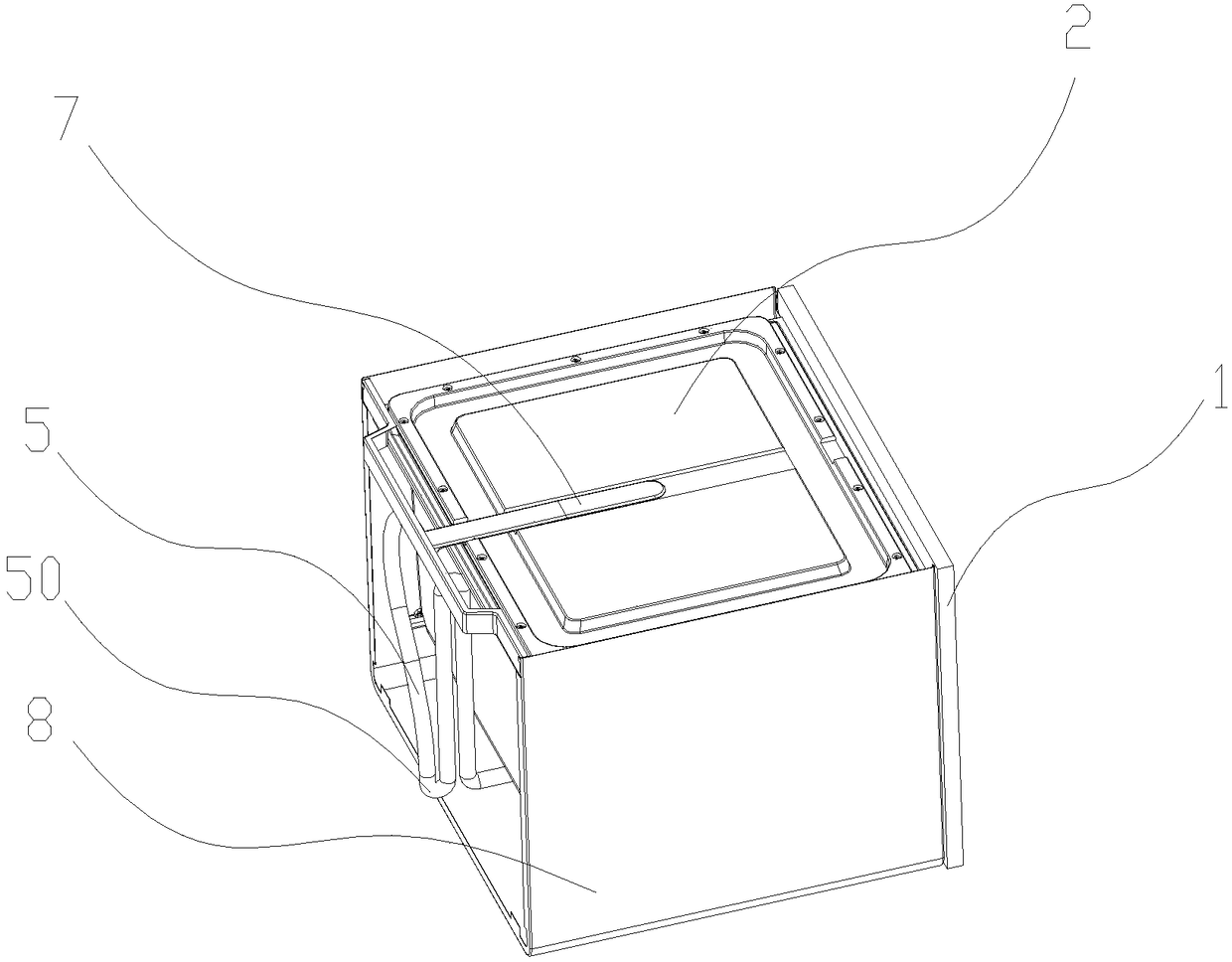

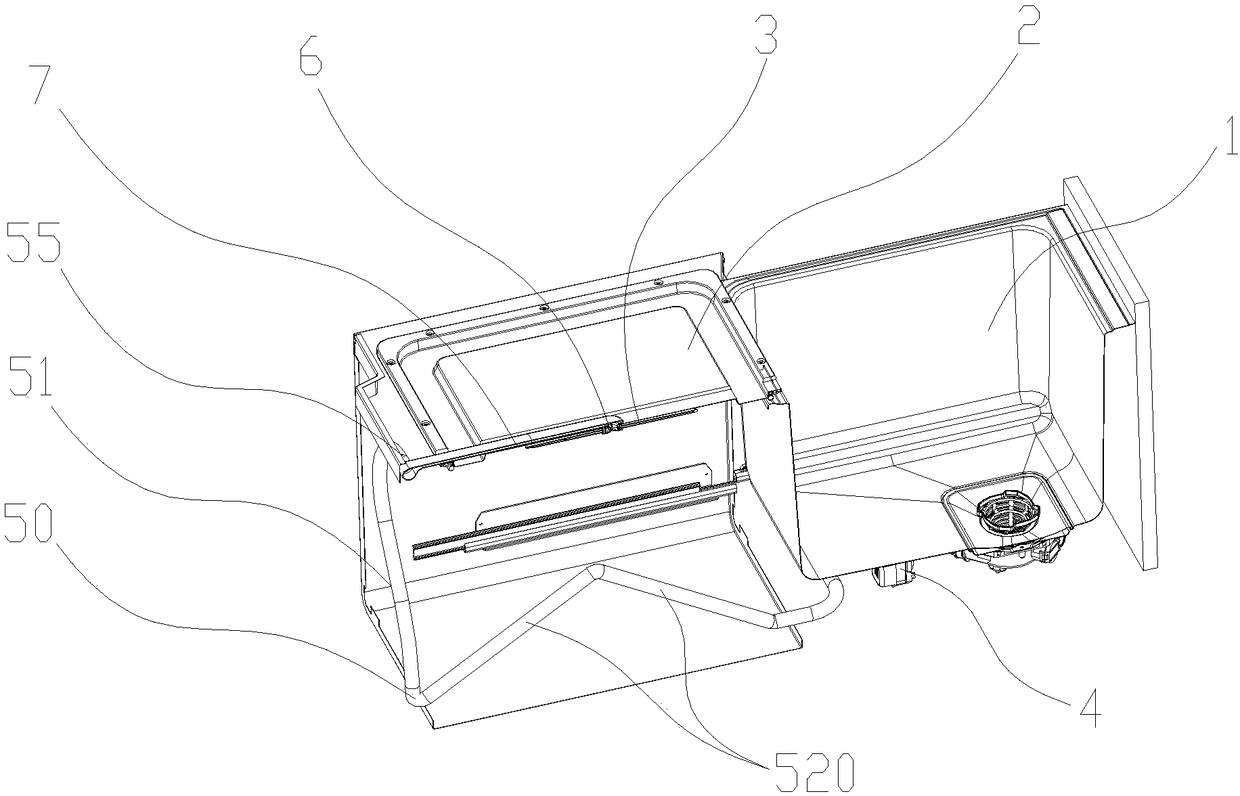

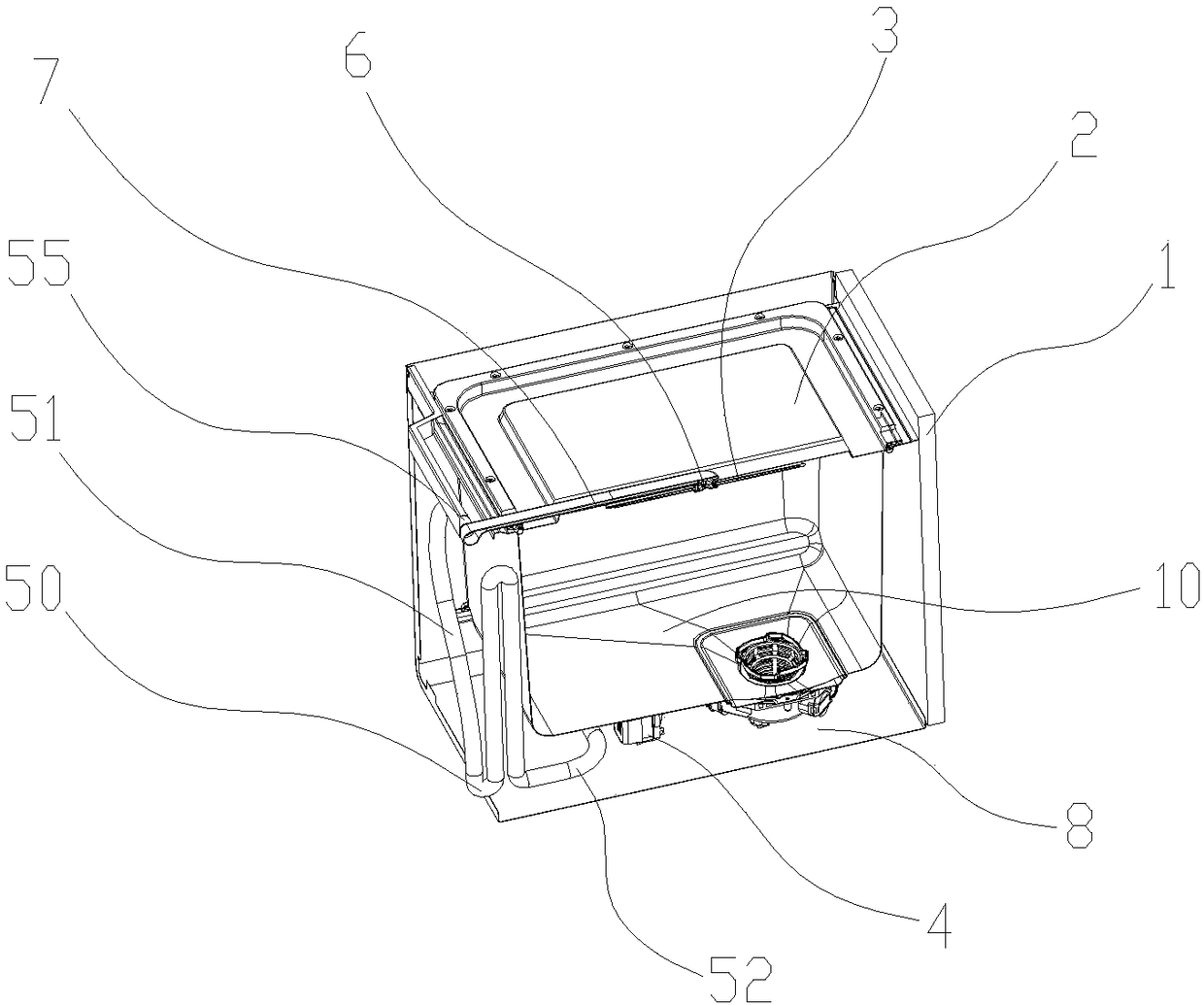

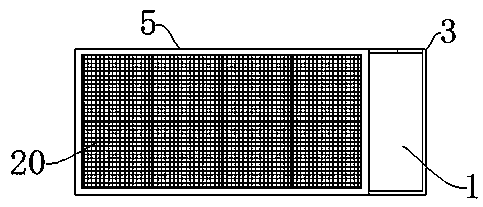

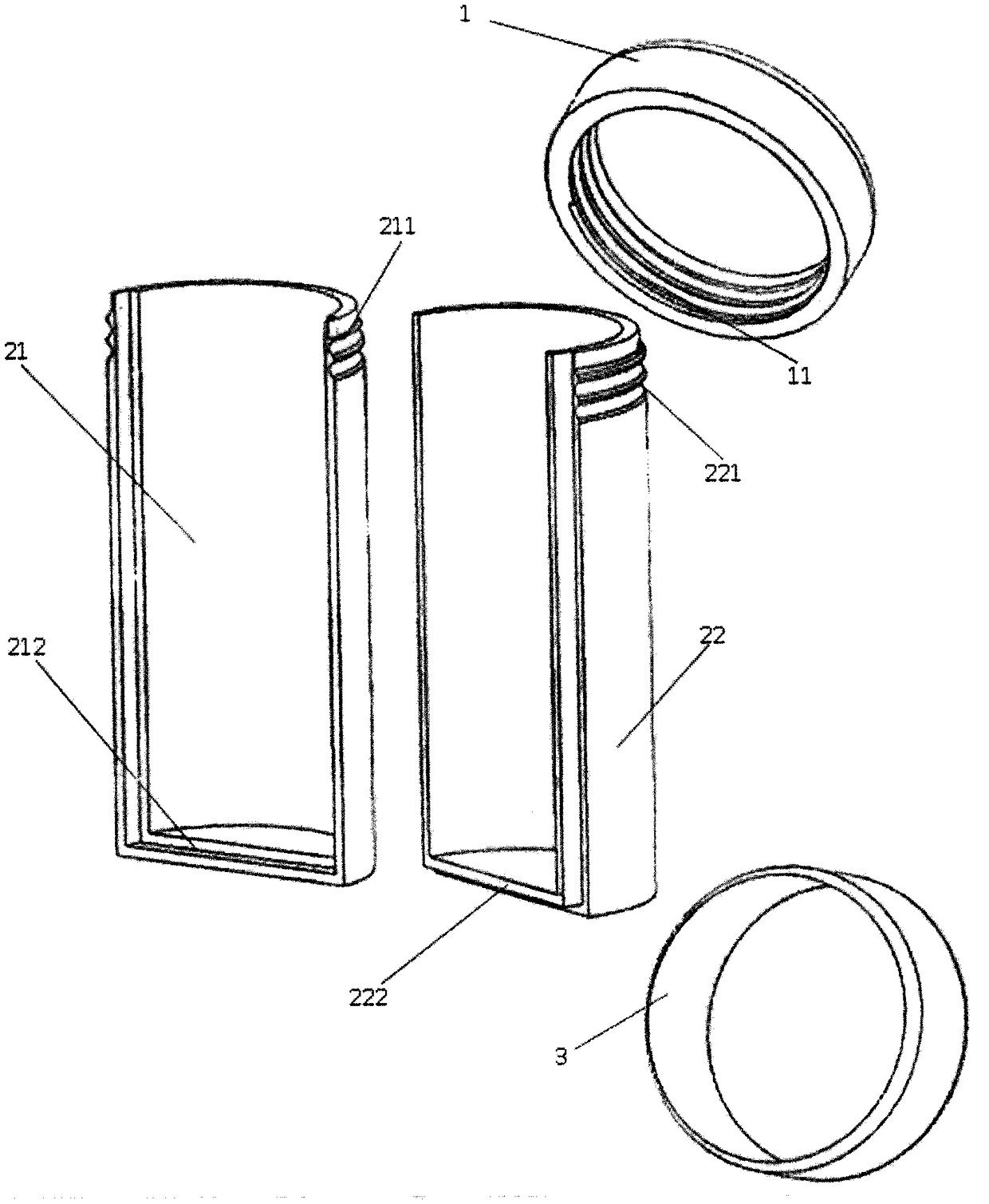

Drawer type dish washer with external water pipe

PendingCN108185941AImprove positionIncrease the angleTableware washing/rinsing machine detailsCleaning equipmentWater sprayMechanical engineering

The invention relates to the technical field of dish washers, in particular to a drawer type dish washer with an external water pipe. The dish washer comprises a housing, a cover plate is arranged onthe housing, a movable drawer is arranged on the housing, a top spraying arm with water spraying holes is arranged on the cover plate, a circulation water pump is arranged on the bottom surface of thedrawer, the circulation water pump is communicated with the top spraying arm through a top spraying water inlet pipe, the top spraying water inlet pipe is arranged outside the drawer, and the top spraying water inlet pipe can move along with the drawer. The invention further provides a drawer type dish washer with up and down spraying arms. The dish washer has the advantages that the cleaning degree is high and the dish washer has no dead cleaning space.

Owner:VATTI CORP LTD

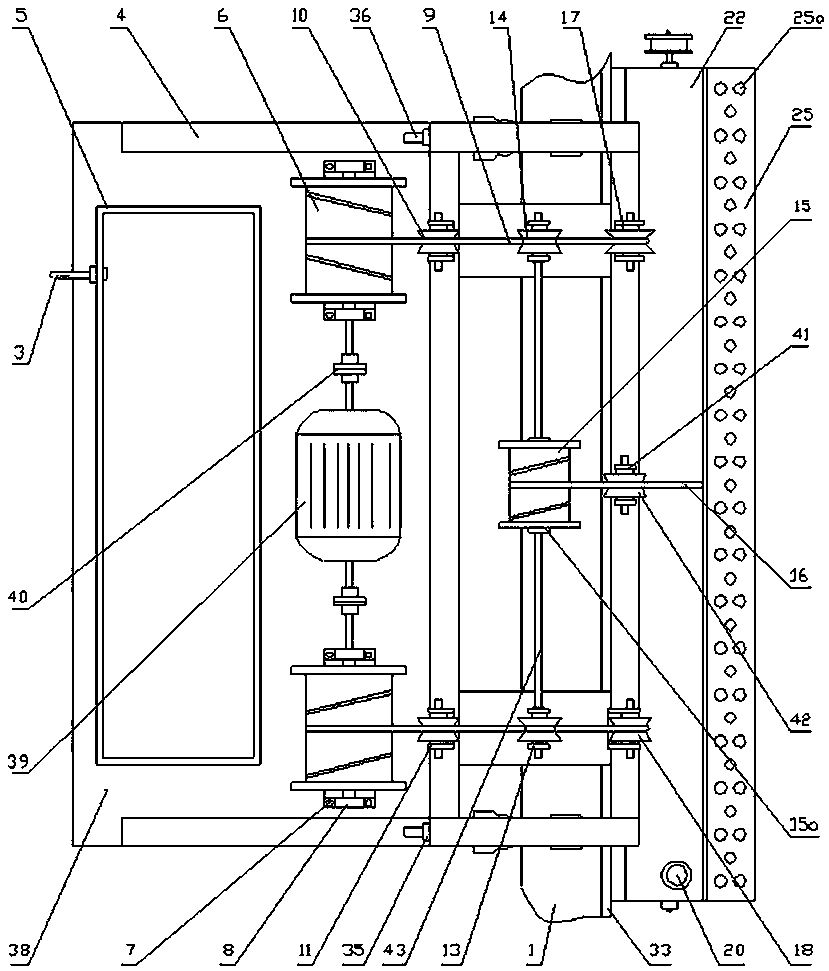

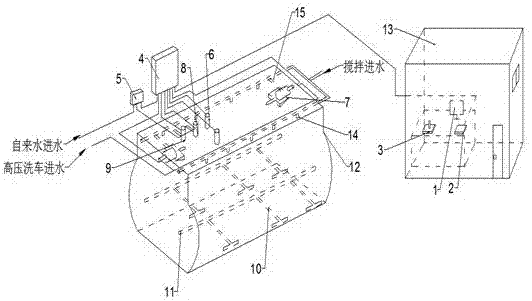

Stirring device capable of monitoring concrete slump degree and automatically cleaning

InactiveCN107263708AAdjust in timeEarly judgment of slumpMixing operation control apparatusCement mixing apparatusElectricityDisplay device

The invention discloses a stirring device capable of monitoring a concrete slump degree and automatically cleaning. The stirring device capable of monitoring the concrete slump degree and automatically cleaning comprises a stirring machine and an operating room, wherein the operating room comprises a display, a video recorder and a rocking rod operating keyboard; the stirring machine comprises a distribution box, a high-pressure water spraying system, a pipeline fan, a butterfly valve, an all-directional high-pressure automatic cleaning machine, a monitor head, an LED (Light-Emitting Diode) lamp, a stirring unit and a stirring machine outer shell; the high-pressure water spraying system, the pipeline fan, the butterfly valve, the all-directional high-pressure automatic cleaning machine, the monitor head, the LED lamp and the stirring unit are all electrically connected with the distribution box; the monitor head and the LED lamp are also connected with the high-pressure water spraying system through a tap water pipe; the all-directional high-pressure automatic cleaning machine is connected with a high-pressure water pipe of a high-pressure vehicle washing machine through a water guide pipe above the all-directional high-pressure automatic cleaning machine. According to the stirring device capable of monitoring the concrete slump degree and automatically cleaning, the factory slump degree of concrete can be controlled very well, qualified and uniform concrete is produced, unnecessary economic loss is reduced for a concrete stirring plant, and meanwhile, that the stirring machine can be internally cleaned without dead angles is ensured.

Owner:黄建坤

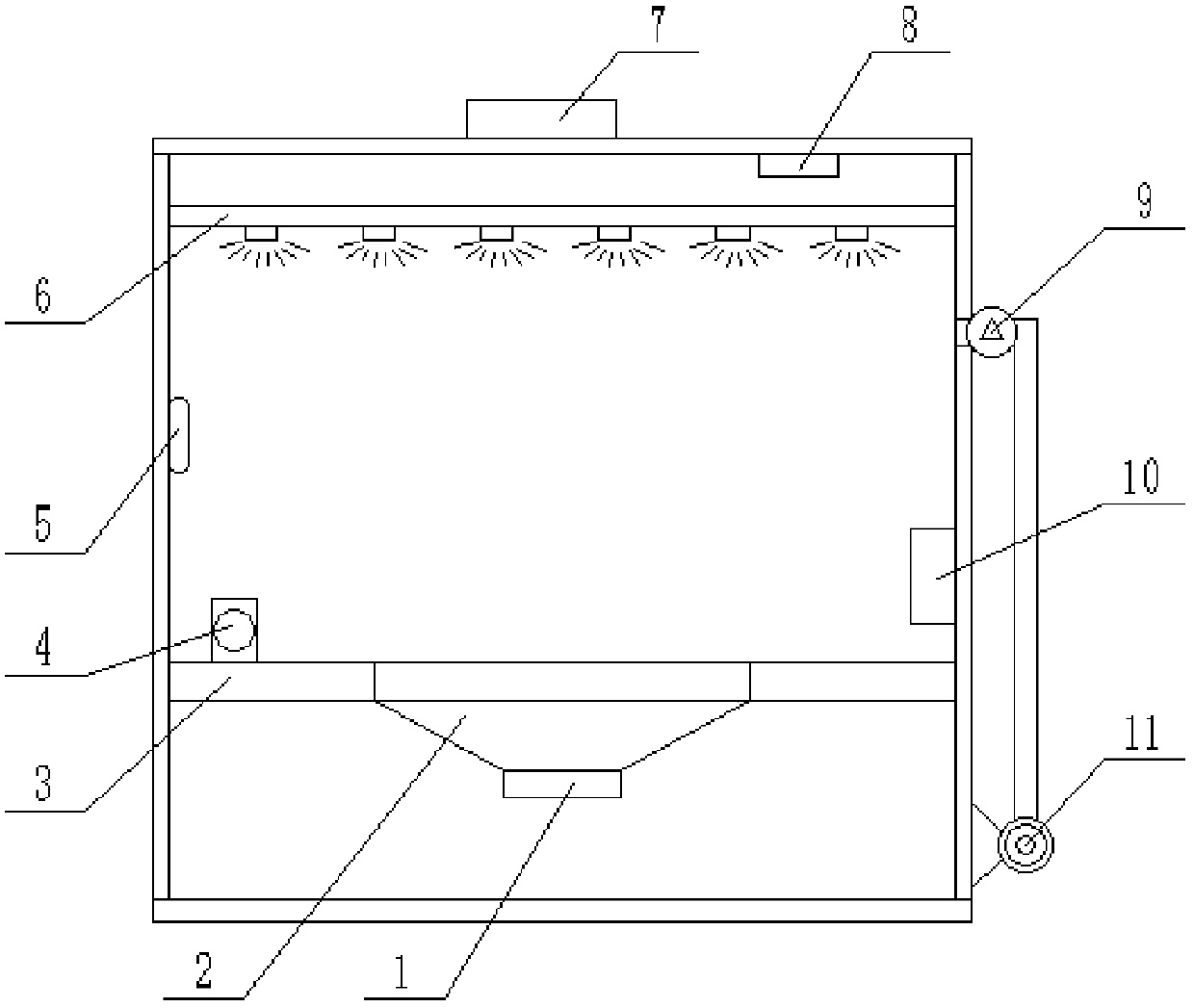

Spring automatic intelligent cleaning and drying device

InactiveCN107588608AAchieve cleaningAchieve dryingDrying solid materialsDrying machines with local agitationWater qualityLiquid storage tank

The invention discloses a spring automatic intelligent cleaning and drying device. The device comprises a cleaning and drying box, an ultrasonic generator, a controller and a heating dryer, wherein anobject carrying plate is arranged at the bottom of the cleaning and drying box, a water quality monitor is installed on the object carrying plate, and a liquid discharging pipe is arranged at the bottom of the object carrying plate; a liquid discharging control valve is arranged at the bottom of the liquid discharging pipe, and a liquid storage tank is arranged at the lower end of the cleaning and drying box; one side of the cleaning and drying box is provided with the controller, and the top of the cleaning and drying box is provided with a humidity sensor; the heating dryer is arranged in the cleaning and drying box, a liquid level meter is installed on one side of the inner wall of the cleaning and drying box, and the other side of the inner wall of the cleaning and drying box is provided with the ultrasonic generator. The spring automatic intelligent cleaning and drying device has the advantages that intelligent automatic cleaning and drying can be achieved, ultrasonic waves are used for cleaning, and cleaning is free of dead corners.

Owner:SHENGZHOU AILANER KITCHEN & BATH TECH

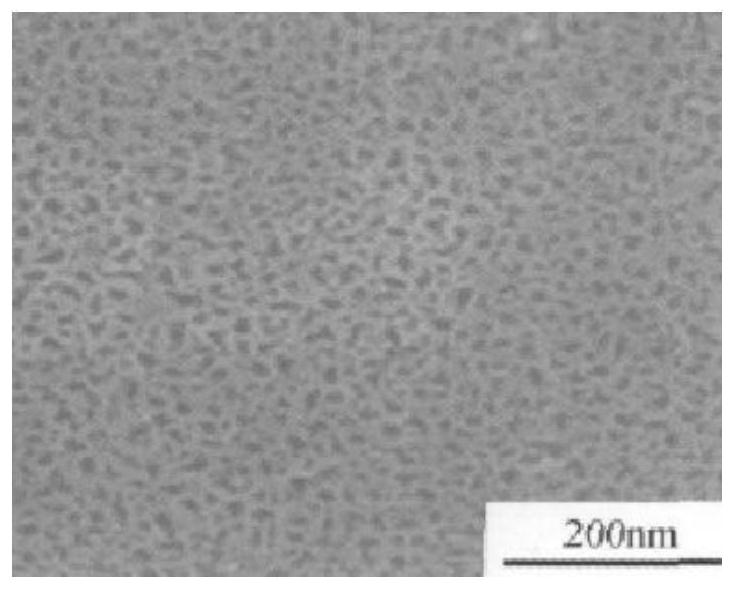

Cleaning device and cleaning method for optical coating clamp

ActiveCN111715605AShort cleaning timeImprove cleaning efficiencyDrying solid materials without heatCleaning using liquidsEngineeringElectrochemical corrosion

The invention relates to a cleaning device and a cleaning method for an optical coating clamp. The cleaning device for the optical coating clamp comprises a direct-current power supply, an ultrasonicoscillator and a reaction container. The cleaning method of the cleaning device for the optical coating clamp comprises the following steps that (1), the direct-current power supply is started, and the optical coating clamp is subjected to electrochemical corrosion; (2), the ultrasonic oscillator and the direct-current power supply simultaneously work to clean the optical coating clamp; (3), the optical coating clamp is washed; (4), the optical coating clamp is blown for drying; and (5), the optical coating clamp is dried. According to the cleaning device and method for the optical coating clamp, the optical coating clamp is pretreated firstly, then a surface film layer of the optical coating clamp is treated through the method of combining electrochemical corrosion and ultrasonic oscillation, and compared with a traditional chemical soaking method and a traditional ultrasonic cleaning method, the cleaning time is short, and the cleaning efficiency is high.

Owner:潍坊华光光电子有限公司

Dish-washing machine

InactiveCN104586333AGood scrubbing abilityImprove efficiencyTableware washing/rinsing machinesEngineeringMotor drive

The invention discloses a dish-washing machine which is all-around in spraying and good in washing effect. In order to overcome defects that an existing dish-washing machine is slow in cleaning dishes and not high in efficiency, the invention provides the dish-washing machine which is all-around in spraying and good in washing effect. The dish-washing machine comprises a machine body, a spray device and a circulating device, wherein the machine body is a box structure; a dish-washing rack for placing dishes to be washed is arranged in an inner cavity of the machine body; the spray device comprises a motor, a spray tube and a pressure cover, the spray tube is arranged above the motor, and the motor drives the spray tube to rotate; the spray head is arranged at the upper part of the spray tube, and the pressure cover covers the spray head of the spray tube; spray holes are formed in the spray tube and the spray head; the circulating device comprises a pump, a liquid return slot and a slot, the liquid return slot is formed below the machine body, and the liquid return slot is communicated with the bottom of the washing slot of the machine body. Compared with the existing dish-washing machine, the dish-washing machine disclosed by the invention has the characteristics of being small in mounting space, high in washing efficiency and free of a washing dead angle.

Owner:ZHEJIANG JIAQI MACHINERY CO LTD

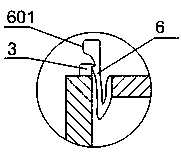

VR glasses structure convenient to dismount and wash

InactiveCN108227212AEasy to disassembleNo dead angle cleaningOptical elementsEngineeringGlass structure

The invention discloses a VR glasses structure convenient to dismount and wash. The VR glasses structure comprises a casing seat, wherein an opening is formed in the back end of the casing seat, a glasses frame is formed, a screen is mounted on the front side of the casing seat, the upper edge of the front side of the casing seat is hinged with an upper cover through hinges I, and the middle of the casing seat is hinged with a drawer type lens frame; lens fixing devices are mounted on the lens frame, and the lens frame is connected with the casing seat through a hinge II; fasteners I matched with the casing seat are fixed on the upper cover, and a fastener II matched with the casing seat is fixed on a casing of the lens frame. The VR glasses structure has the benefits as follows: the VR glasses structure is convenient to dismount and has no dead corners during washing; lenses are not required to be dismounted during washing.

Owner:国科泰达科技(南京)有限公司

Novel intelligent stirring tank for tea oil production

PendingCN113856531AStir wellQuick disassemblyTransportation and packagingRotary stirring mixersElectric machineryProcess engineering

The invention discloses a novel intelligent stirring tank for tea oil production. The stirring tank comprises a tank body, a feeding port, a discharging port, a stirring assembly, a mounting assembly, a rotating assembly, a control panel, a door, a motor, a first sleeve, a first rack, a sliding groove, a clamping groove, a second sleeve, a second rack, a sliding block, a first rotating shaft, a first gear, a second rotating shaft, a second gear, a third gear, stirring blades, a first through groove, a mounting plate, a second through groove, a mounting table, a fixing block, a pneumatic telescopic rod and a third rotating shaft. Compared with existing stirring tanks used for tea oil production, the designed stirring assembly can fully stir raw materials, the production time is shortened, and the production efficiency is improved; the mounting assembly designed by the invention can be used for quickly disassembling and assembling the stirring blades, so that the stirring blades can be conveniently maintained and overhauled; and the rotating assembly designed by the invention can ensure that the stirring blades can be cleaned without dead angles when the interior of the stirring tank is cleaned.

Owner:江西佳诺机械科技股份有限公司

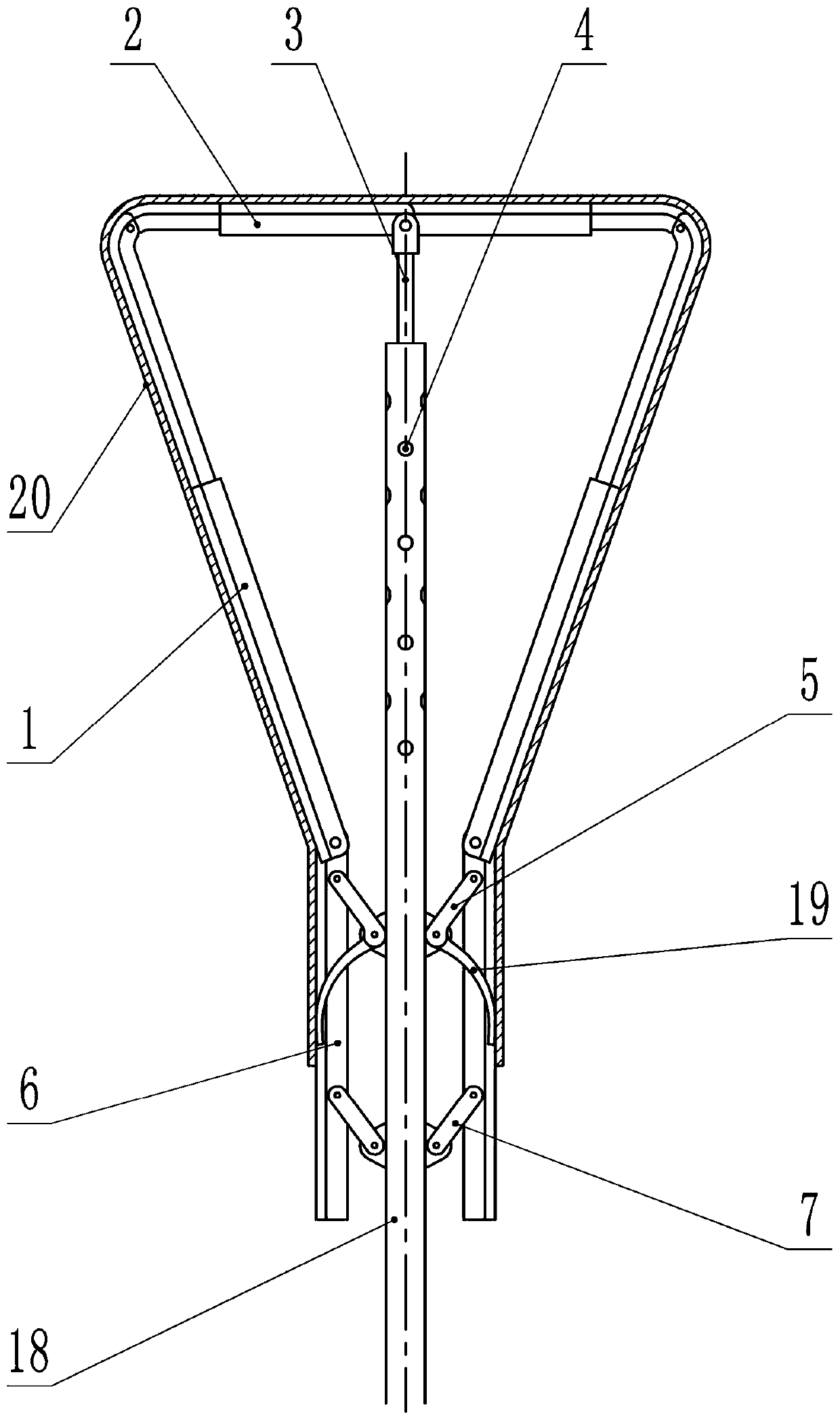

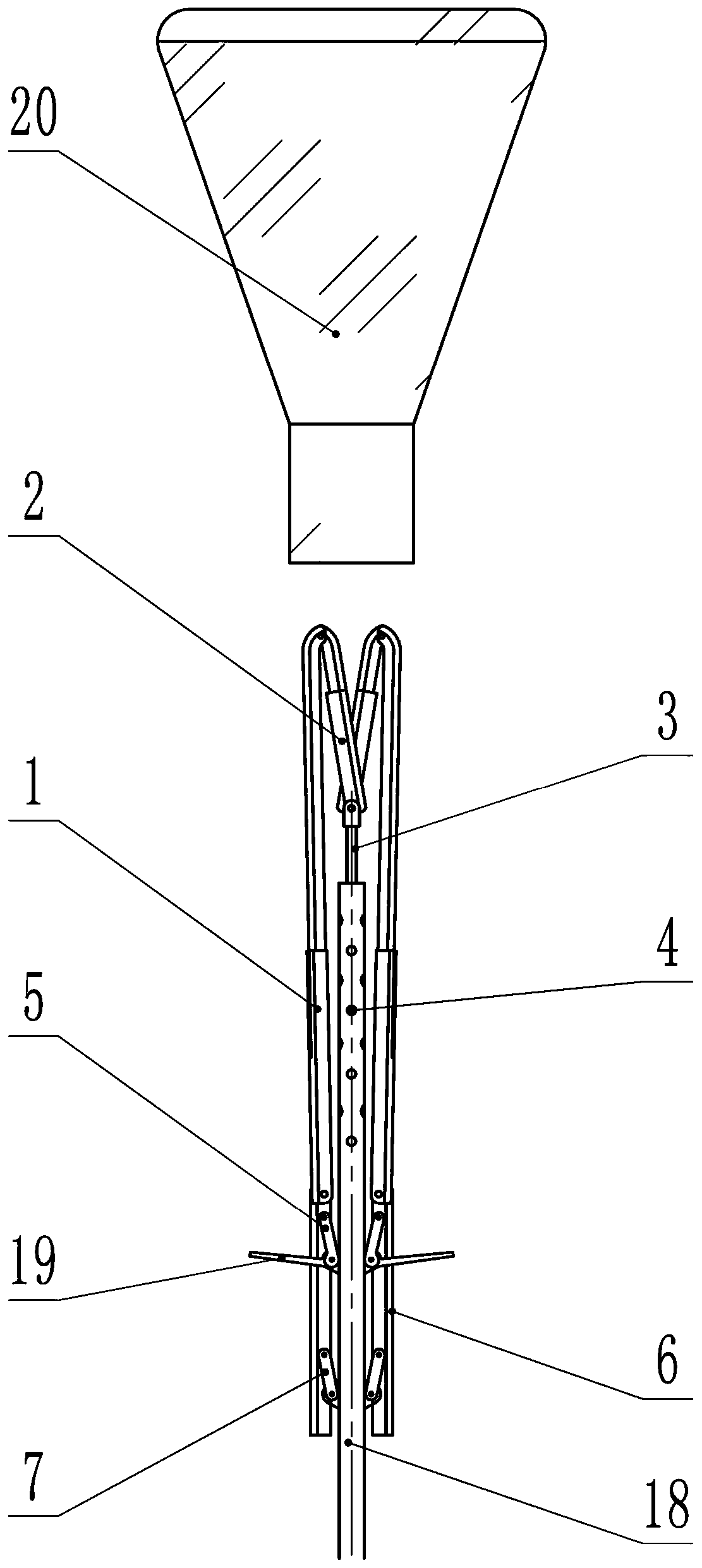

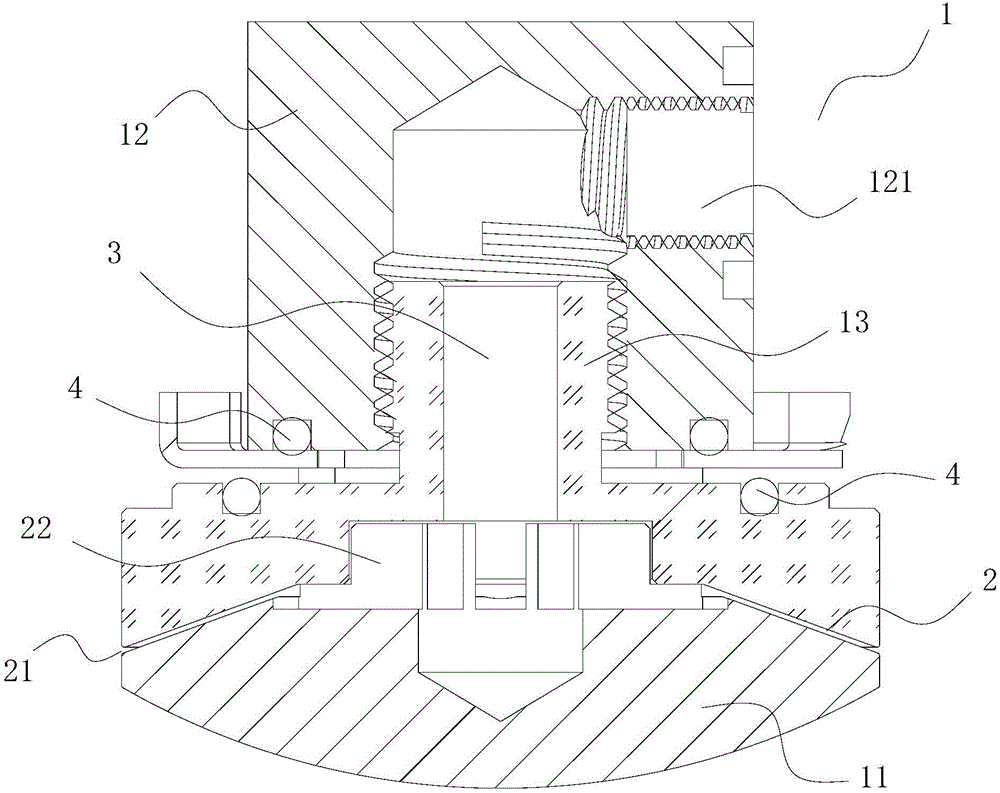

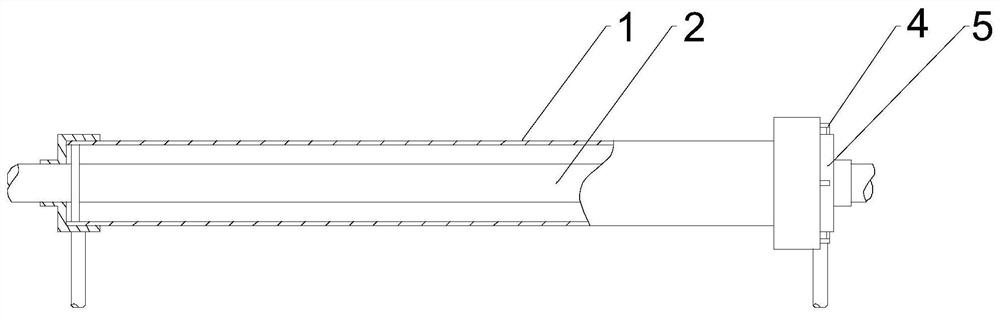

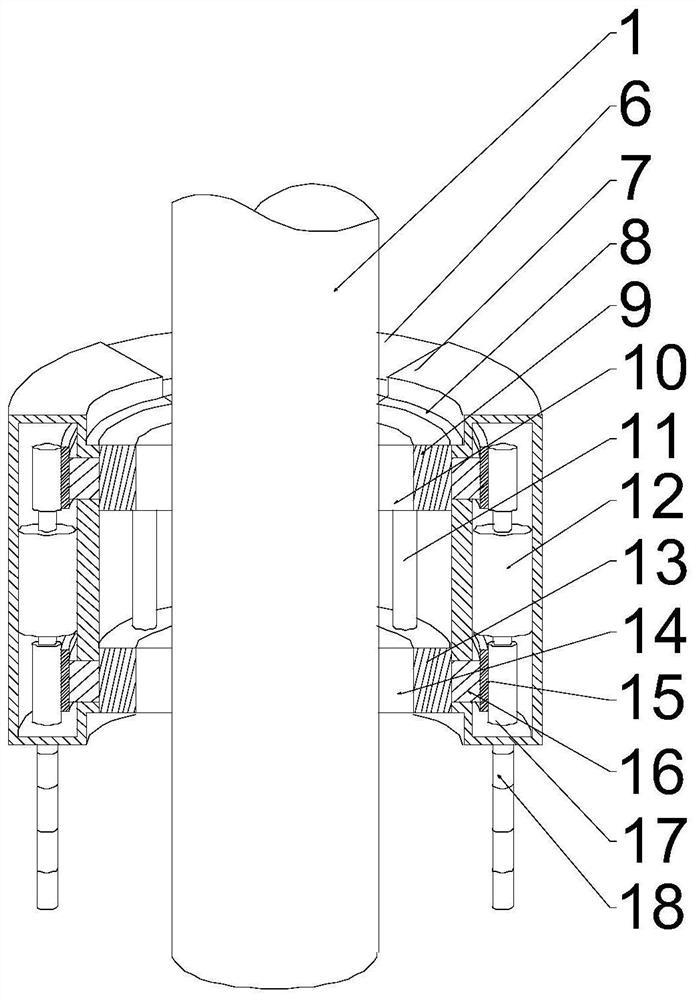

Adjustable absorber head and absorber

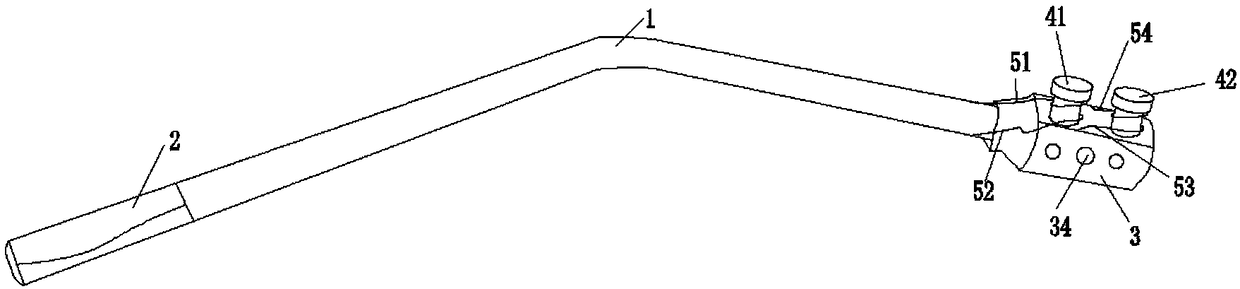

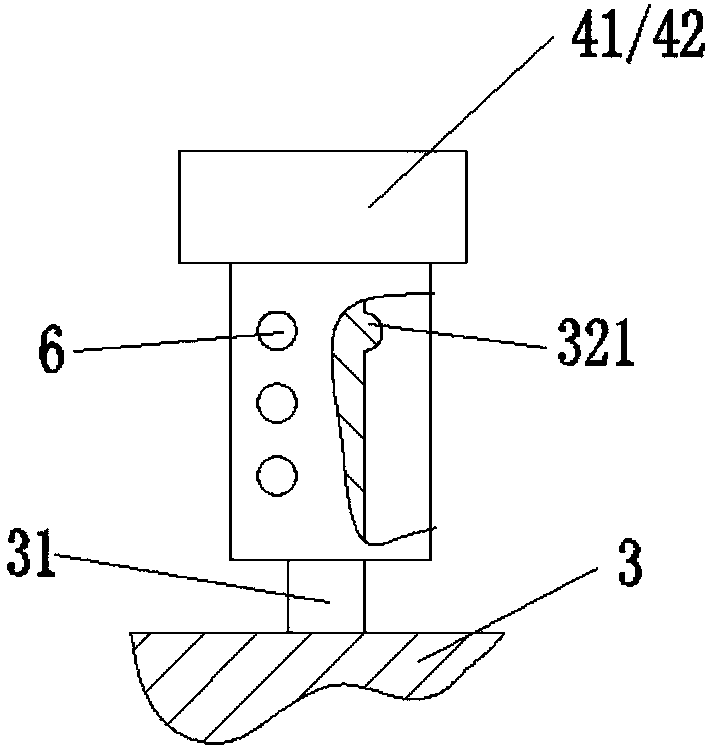

PendingCN108175878AKeep clearSolve dirty cleaningIntravenous devicesSuction irrigation systemsEngineering

The invention discloses an adjustable absorber head and an absorber. The adjustable absorber head comprises an absorbing pipe, a first hose, an operating handle, a guide wheel and a connecting wire; the first hose is connected to the left end of the absorbing pipe, and the operating handle is fixed to the right end of the absorbing pipe; the connecting wire comprises an upper connecting wire body,a lower connecting wire body, a left connecting wire body and a right connecting wire body; the guide wheel comprises a first guide wheel body and a second guide wheel body; the left end of the upperconnecting wire body is fixed to the top face of the left end of the first hose, the left end of the lower connecting wire body is fixed to the bottom face of the left end of the first hose, the leftconnecting wire body is fixed to the front face of the left end of the first hose, and the right connecting wire body is fixed to the rear face of the left end of the first hose; the upper connectingwire body and the lower connecting wire body are wound on the first guide wheel body, and the left connecting wire body and the right connecting wire body are wound on the second guide wheel body. Through the arrangement of the guide wheel and the connecting wire, dead-angle-free deflection of the absorber head from 360 degrees is achieved, and waste liquid at the operation part is thoroughly removed to ensure that the operation view is clear and increase the operation success rate.

Owner:WUXI NO 2 PEOPLES HOSPITAL

Lamp shell cleaning device for projection lamp production and cleaning process thereof

The invention discloses a lamp shell cleaning device for projection lamp production and a cleaning process thereof. The lamp shell cleaning device for projection lamp production comprises a water tank; an operation panel is installed on the front side of the water tank, a filter screen and a semi-permeable membrane are installed in the water tank, a cleaning box and a soaking pool are installed above the water tank, a water inlet pipe is installed on the upper portions of the front sides of the cleaning box and the soaking pool, and a support is fixedly connected to the tops of the cleaning box and the soaking pool. According to the lamp shell cleaning device for projection lamp production and the cleaning process thereof, the soaking pool is arranged to soak a lamp shell, so that the lampshell is easier to clean, the lamp shell is cleaned through ultrasonic waves, so that the lamp shell is cleaned more cleanly, the cleaning efficiency is higher, no dead angle exists in ultrasonic cleaning, cleaning water is recycled, water resources are saved, cleaning spray heads spray pressurized water flow to the lamp shell to further wash away residual cleaning agents and aluminum powder on the lamp shell, through arrangement of a first rotatable clamp head and a second rotatable clamp head, so that the cleaning spray heads rotationally wash the lamp shell, no dead angle exists during washing, and a spring is matched with a pressing rod so that the lamp shell can be conveniently taken and placed.

Owner:HEHONG ELECTRICAL CO LTD

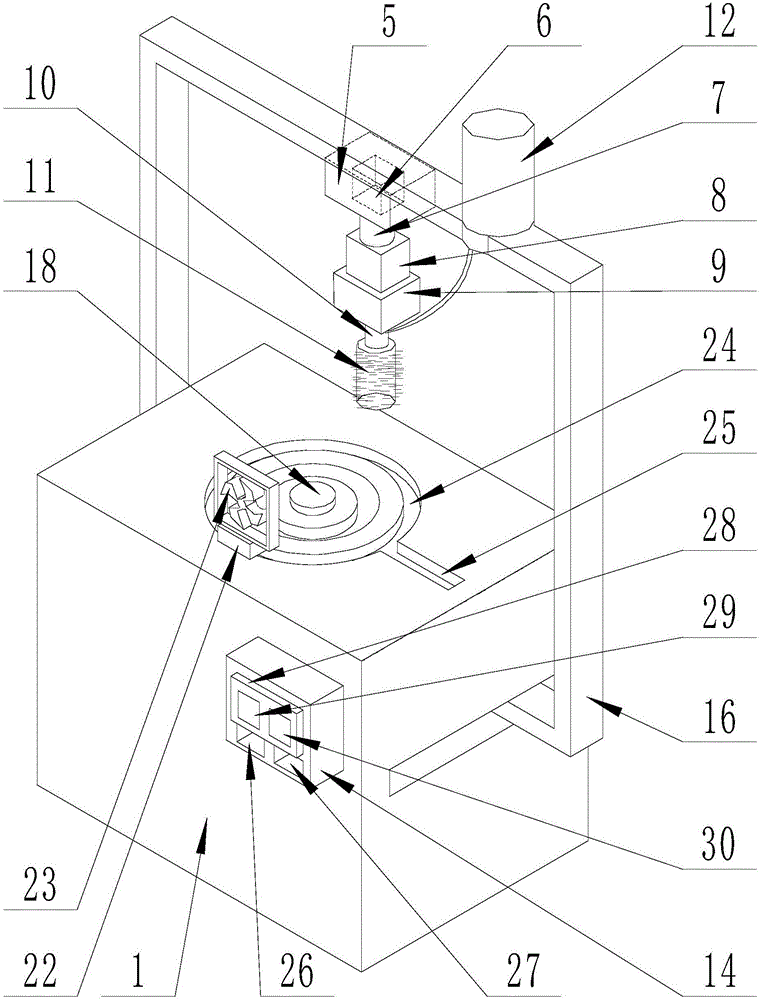

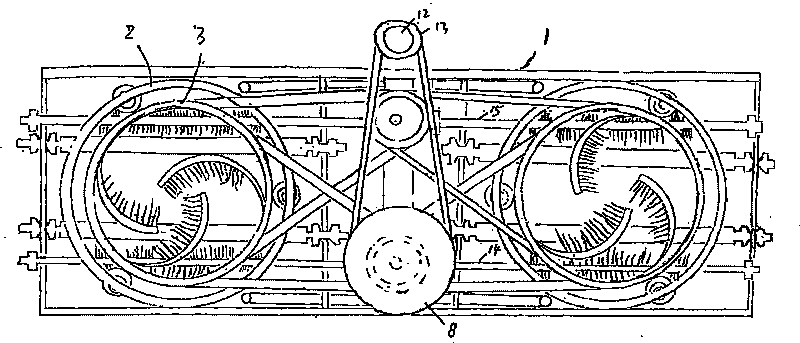

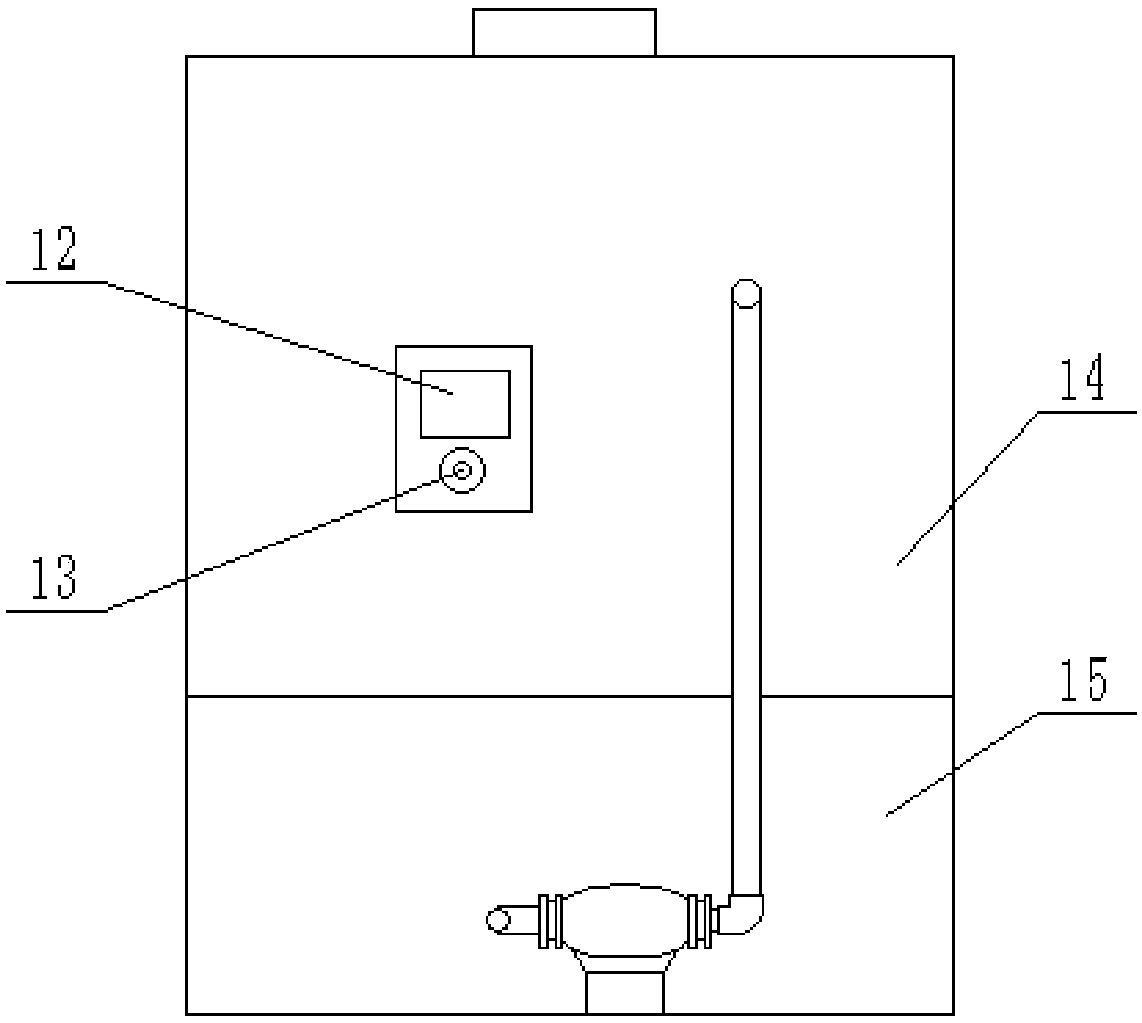

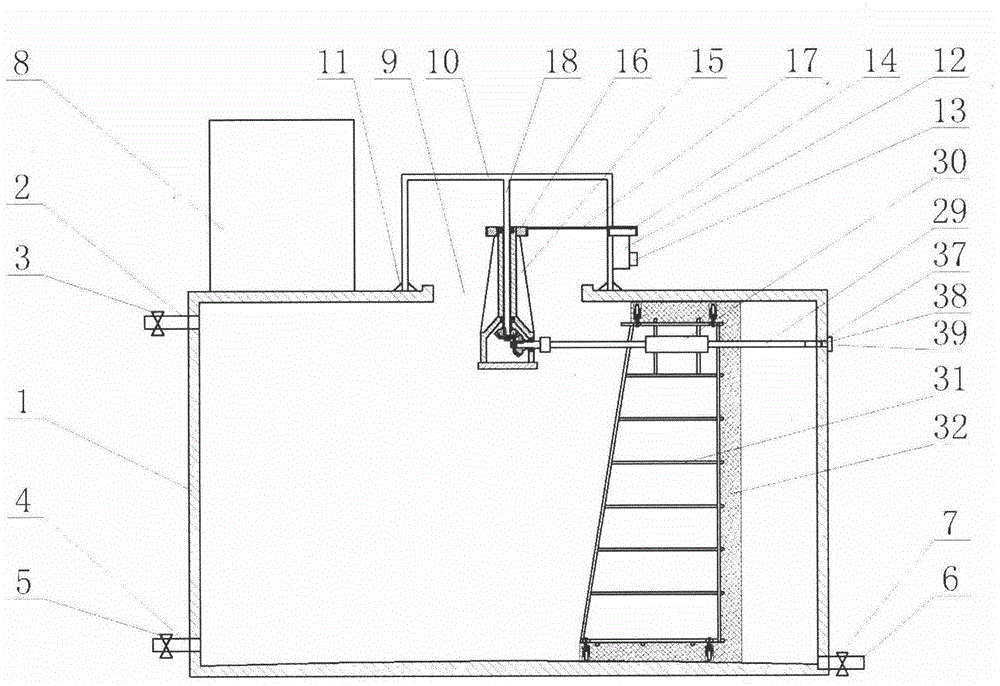

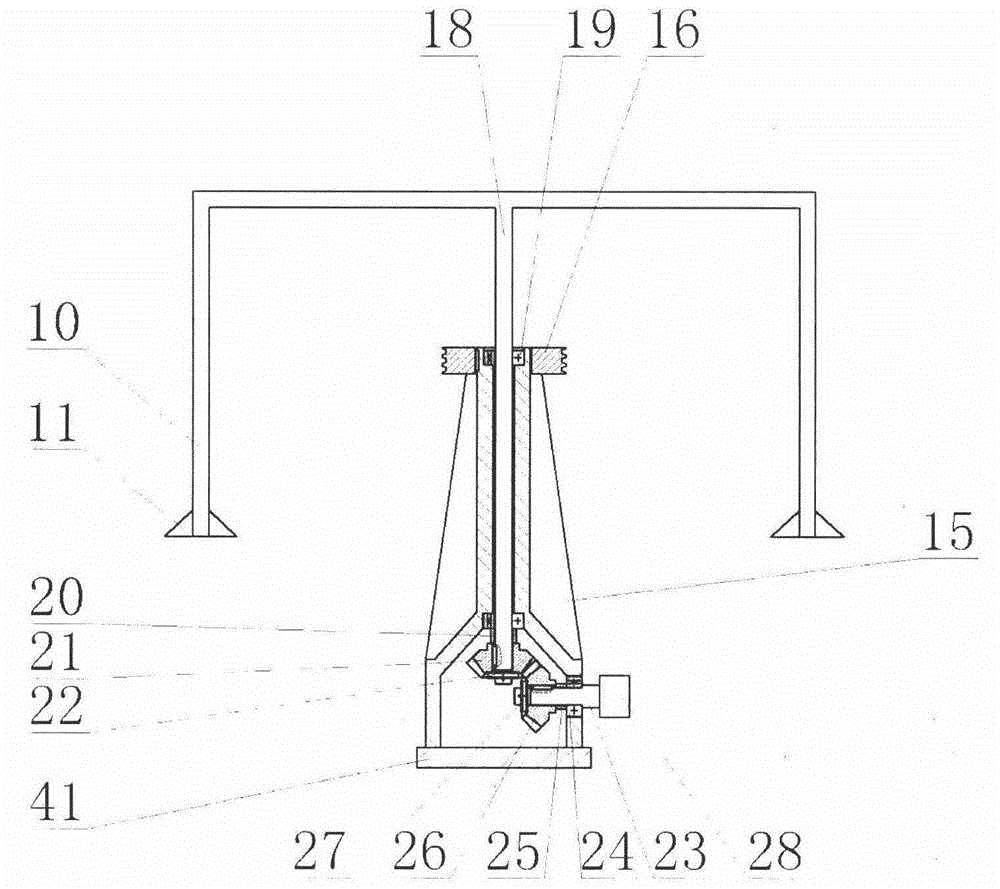

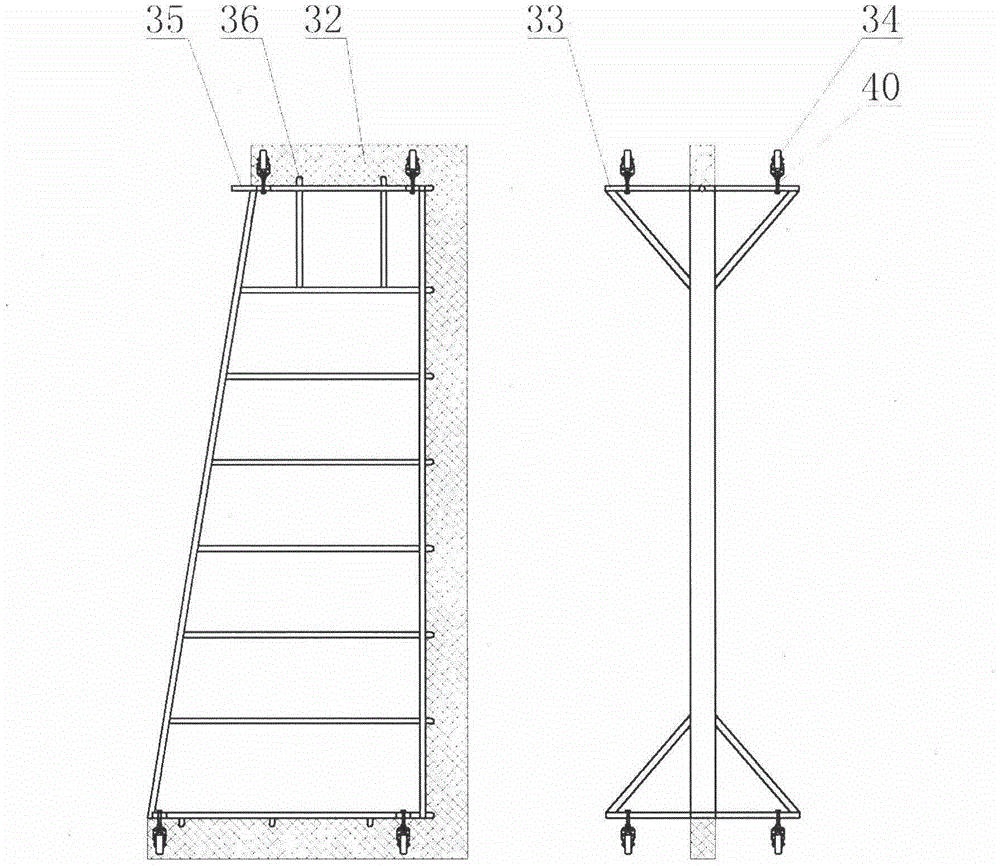

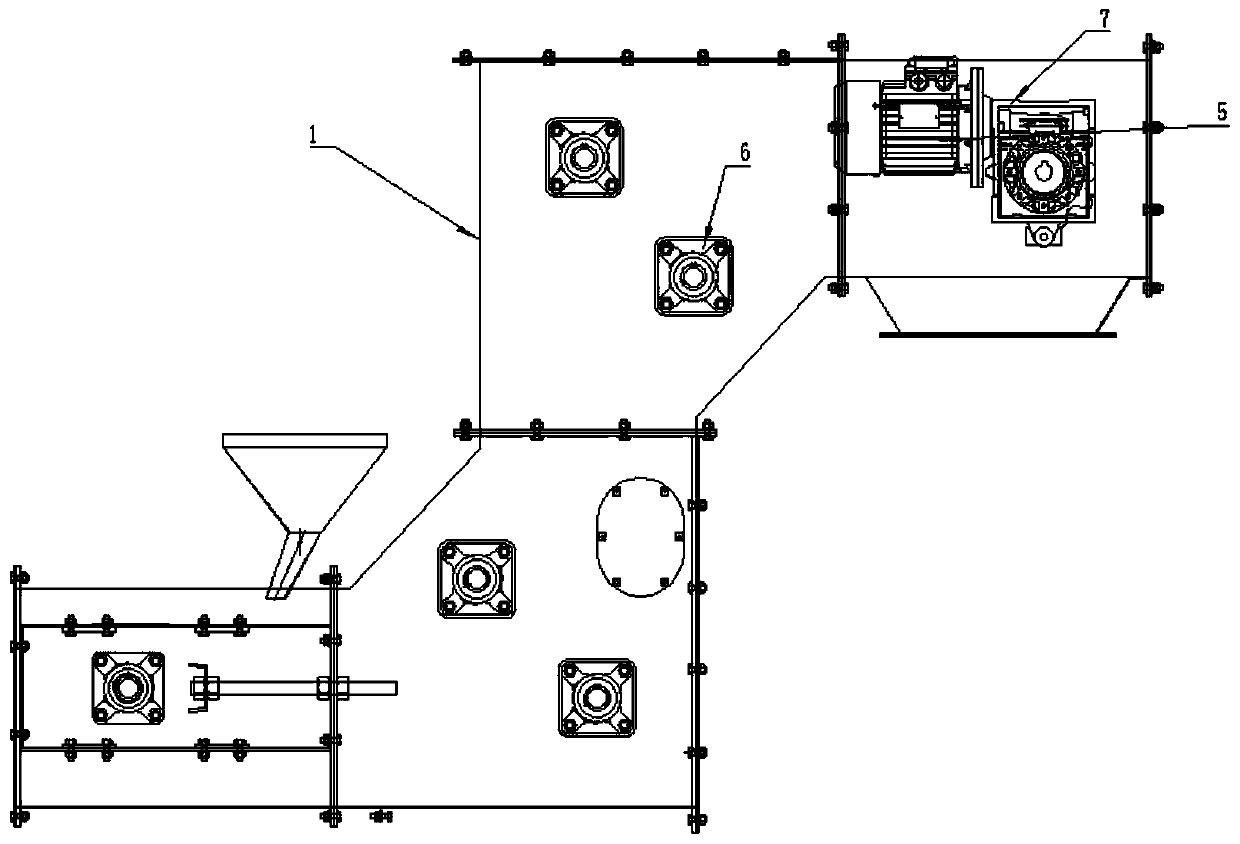

Automatic cleaning water storage pool

ActiveCN104863213AReduce widthAvoid pollutionHollow article cleaningWater supply tanksEngineeringWater storage

The invention discloses an automatic cleaning water storage pool, and mainly relates to the field of storing tap water. The automatic cleaning water storage pool comprises a water storage pool body, a support, an electromotor, a transmission device and a cleaning frame, a small stand-by pool is arranged at the top of the water storage pool body, a manhole is formed in the water storage pool body, the support is arranged at the top of the manhole, the electromotor is arranged on the support, a fixing shaft is arranged on the support and connected with the transmission device which is composed of bevel gears, a lead screw and a screw nut, the transmission device is connected with the cleaning frame, and the electromotor can drive the cleaning frame to rotate along the fixing shaft and move along the lead screw through the transmission device. The automatic cleaning water storage pool has the advantages that the automatic cleaning water storage pool can replace manual labor to clean the water storage pool, the cleaning frame can be taken out from the water storage pool after cleaning, sundries such as rain water and dust can be effectively prevented from falling into the water storage pool, the operation is easy, the structure is stable, the installation is convenient, dirt is easy to collect, cleaning is conducted effectively, cleaning dead angles do not exist, and water can be supplied while cleaning.

Owner:NANTONG HONGFENG ELECTRO MECHANIC

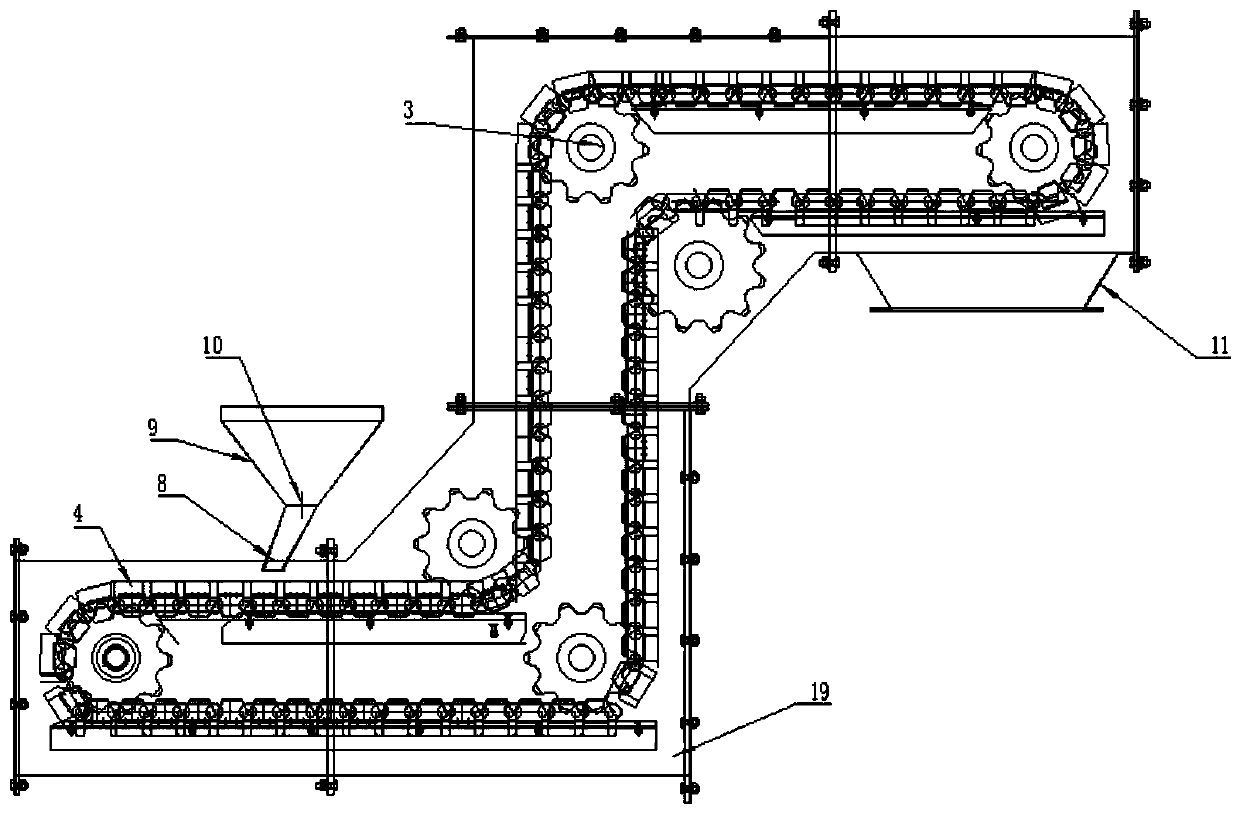

Bucket type Z-type conveyor

PendingCN111573143APrevent leakageIntegrity guaranteedConveyorsConveyor partsFood gradeElectric machinery

The invention relates to a bucket type Z-type conveyor which comprises a shell, a transmission chain, chain wheels, hoppers and a motor. A chain wheel fixing device is arranged on the shell. The chainwheels are fixed in the shell through the chain wheel fixing device. The transmission chain is connected with the chain wheels. The chain wheels are arranged in the shell in bilateral symmetry. The hoppers and the transmission chain are connected and fixed. A motor fixing frame is arranged at the upper end of the shell, and the motor and the shell are connected and fixed through the motor fixingframe. By means of the bucket type Z-type conveyor, dust in the shell can be prevented from adsorbed out to the outer environment; through the secondary and primary hopper design, the defects of material missing, scattering and the like cannot be caused; by means of a food-grade plastic film, safety and sanitation are guaranteed, materials cannot impact on the hoppers, the plastic film can effectively reduce the connecting gap between the hoppers, the problems of hopper metal friction material scattering and the like are effectively solved, material integrity is guaranteed, and the rapid boltconnecting shell is convenient to mount and dismounted; and multiple conveyors are fixedly connected to be used, and practicality is high.

Owner:张家港保税区港中源机械科技有限公司

Cleaning device for conical flasks

The invention discloses a cleaning device for conical flasks, and belongs to the field of cleaning devices for experimental instruments. The cleaning device is characterized by comprising a water basin, a motor, a cleaning device body and water pipes; a vertical barrel structure is arranged on the lower wall of the water basin; a No.1 water pipe penetrates through the barrel structure; the motor and the No.1 water pipe are connected through a transmission device; a No.2 water pipe is arranged below the No.1 water pipe; and the cleaning device body is located above the No.1 water pipe and comprises a central rod, a transverse rod, an inclined rod, a vertical rod, a No.1 connecting rod and a No.2 connecting rod. Compared with the prior art, the cleaning device has the characteristics of highautomation degree and convenience in use.

Owner:潘爱平

Full-automatic ultrasonic shoe washing machine

PendingCN110226910AComprehensive cleaningNo dead angle cleaningFootwear cleanersControl systemCoupling

The invention discloses a full-automatic ultrasonic shoe washing machine, which comprises a machine shell, a dewatering barrel, a water containing barrel and a control system. A heating device is arranged on the outer wall of the water containing barrel. Dewatering holes are formed in the wall of the dewatering barrel. An ultrasonic generator is arranged at the bottom of the dewatering barrel, anda rotary clamping device is arranged in the dewatering barrel. A clamping device comprises a shoe rack, a shoe clamp and a dewatering shaft. The shoe rack is a hollowed-out conical cylinder which iscomposed of an upper circular plate, a lower circular plate and a plurality of supporting plates and is large in top and small in bottom. Shoe clamps which are distributed in a stepped mode are evenlyarranged on the two sides of the supporting plate. Each shoe clamp comprises a shoe rear end fixing open claw, a shoe middle fixing open claw and a shoe front end fixing annular claw, wherein the shoe rear end fixing open claw, the shoe middle fixing open claw and the shoe front end fixing annular claw are located on the upper section and the same in size. A dewatering shaft sequentially penetrates through the centers of the shoe rack, the dewatering barrel and the water containing barrel. The bottom of the dewatering shaft is connected with a speed reducer and a motor through couplers. According to the invention, all parts of a shoe are fixed. The outer surface, the sole and the inner surface of the shoe are thoroughly cleaned and dehydrated through ultrasonic waves at a certain water temperature.

Owner:LUOYANG INST OF SCI & TECH

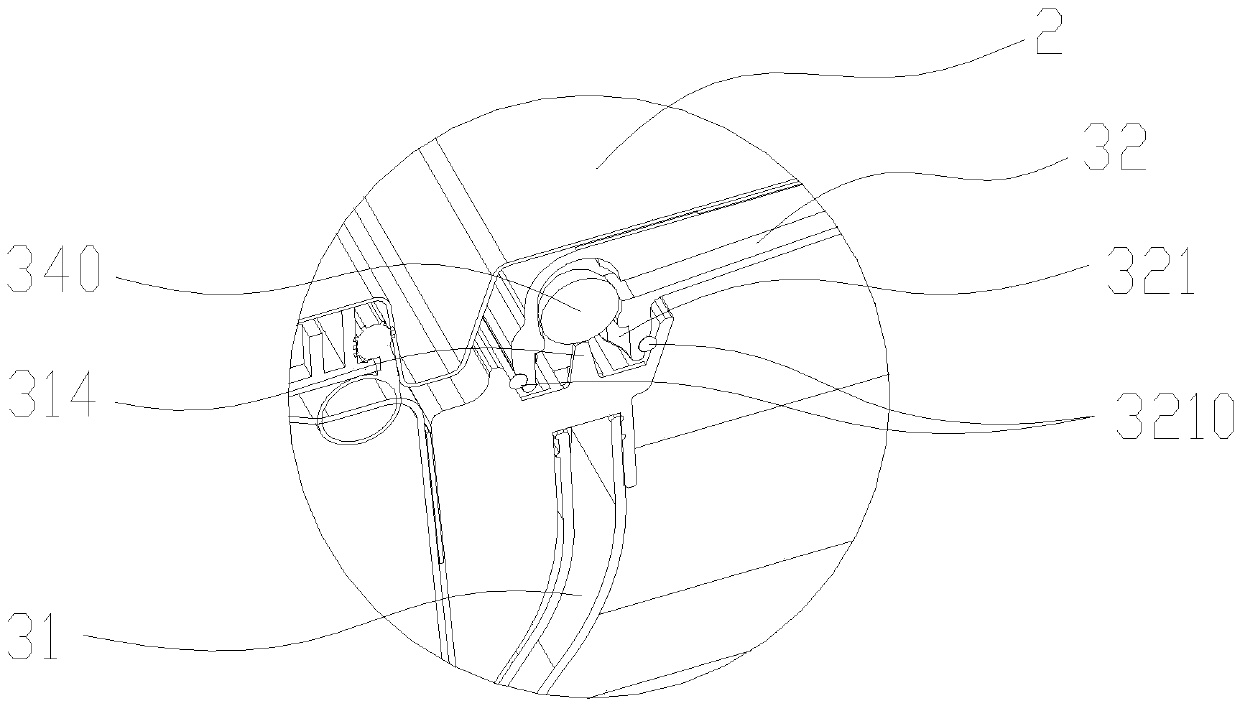

Self-cleaning spray nozzle for range hood and range hood with self-cleaning spray nozzle

ActiveCN106705153AEasy to cleanNo dead angle cleaningDomestic stoves or rangesLighting and heating apparatusSpray nozzleEngineering

The invention discloses a self-cleaning spray nozzle for a range hood and the range hood with the self-cleaning spray nozzle, which belong to the field of range hoods and fittings thereof and are designed for solving the problem that existing devices have a poor cleaning effect. The self-cleaning spray nozzle for the range hood comprises a base and an end cover which are connected, wherein a slit-type spray orifice for spraying a cleaning agent is formed between the base and the end cover; the base is connected to a cleaning agent storage device; and the cleaning agent can be led to the slit-type spray orifice by a cleaning agent channel in the base. The self-cleaning spray nozzle for the range hood has the beneficial effects that the range hood cleaning agent can be sprayed out through the slit-type spray orifice, the point-like spray of the cleaning agent is converted into the surface-like spray of the cleaning agent to ensure that the cleaning agent can cover the whole oil screen, and the cleaning effect is good.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

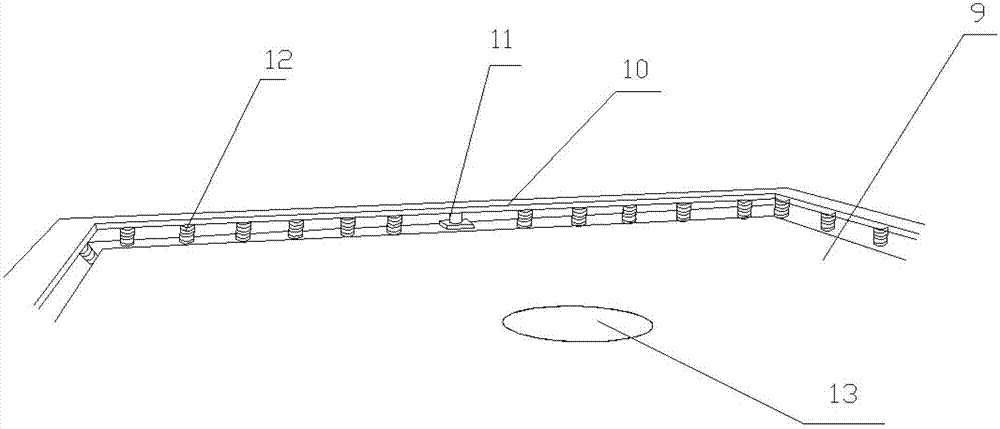

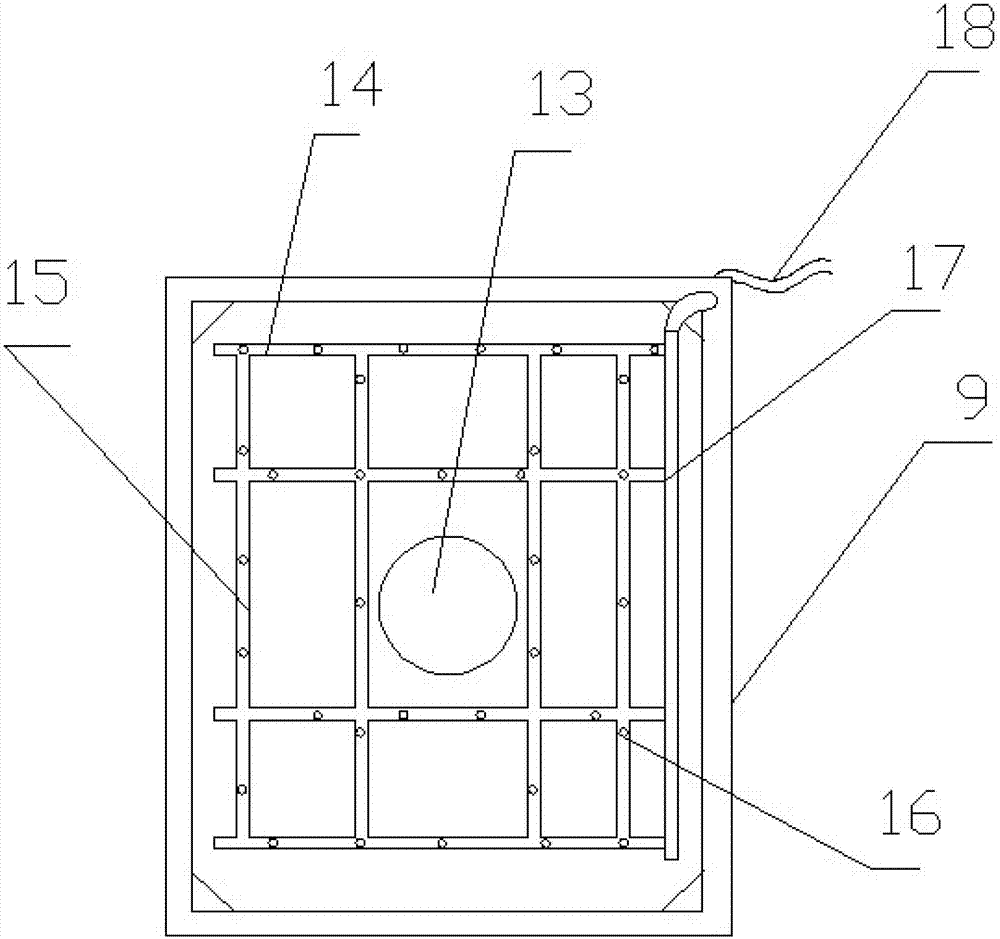

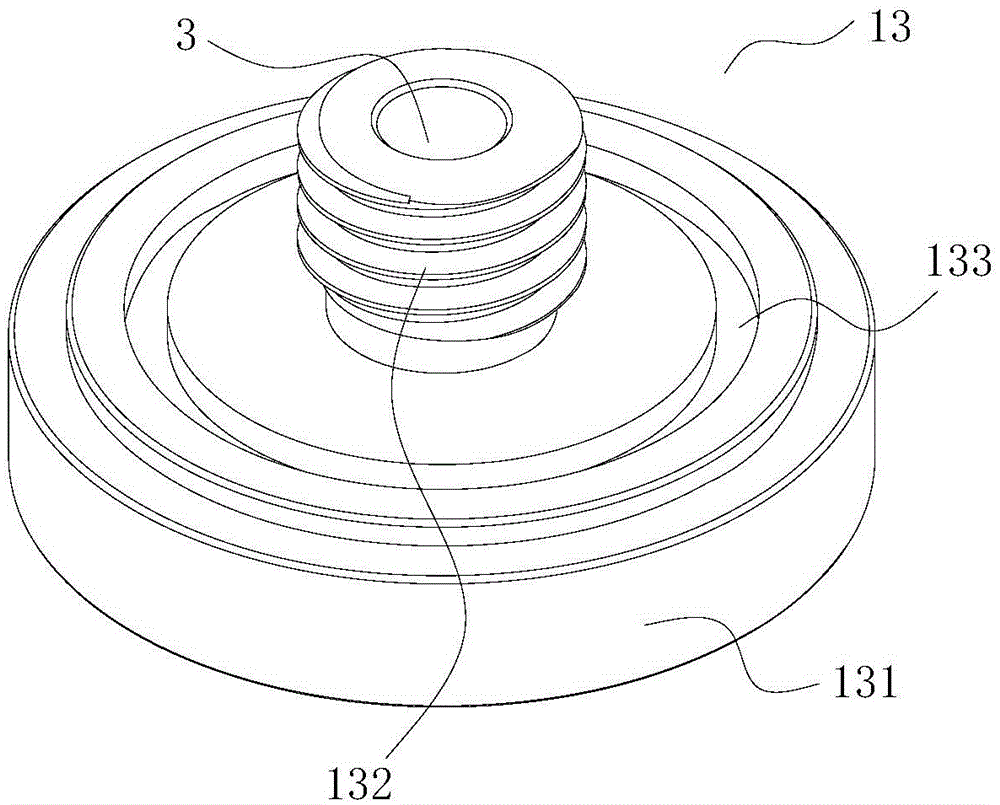

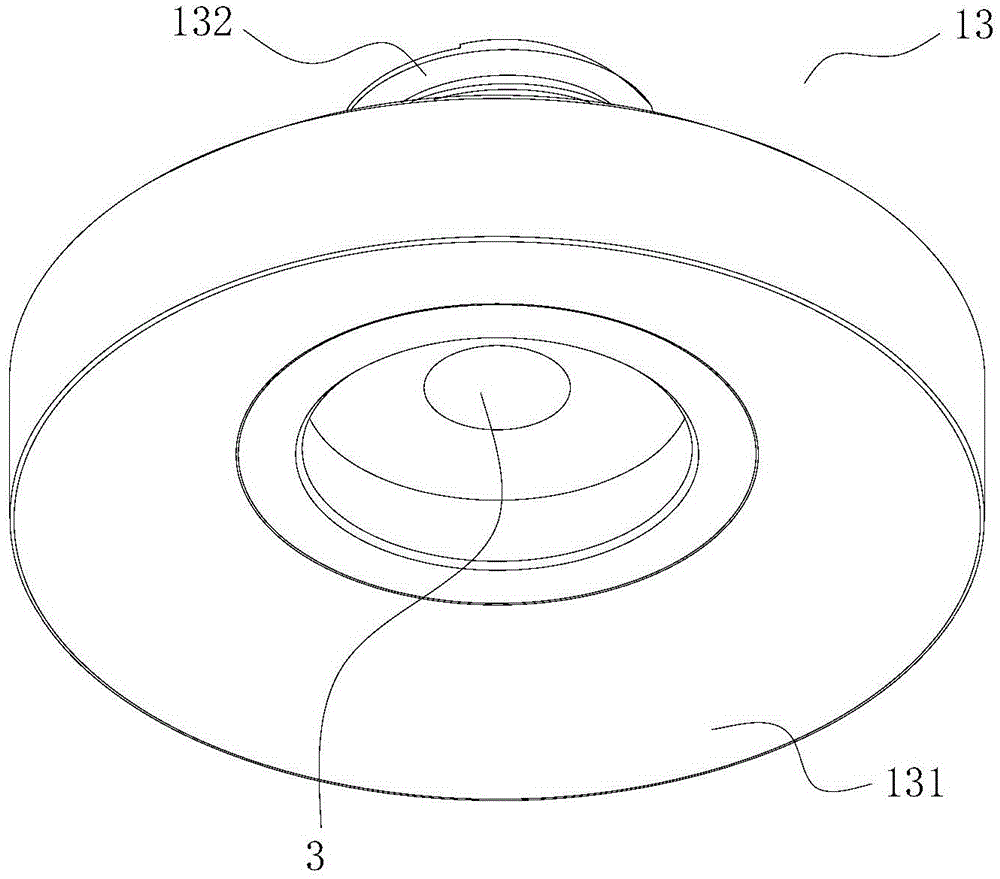

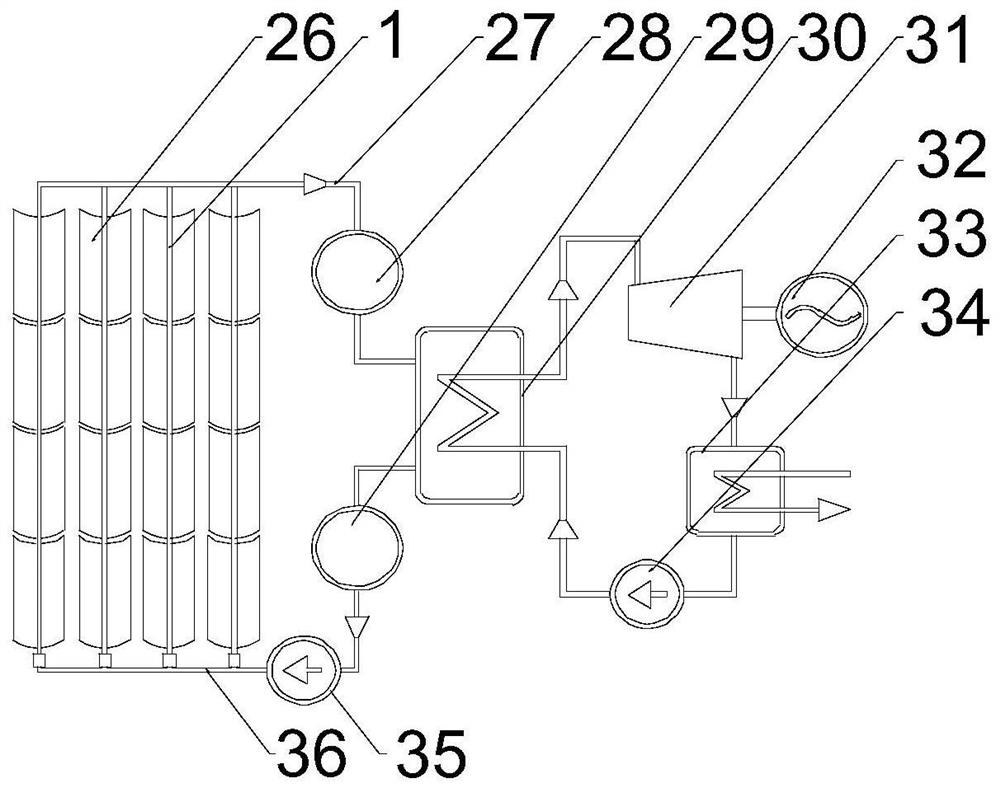

Trough type photo-thermal power generation system

ActiveCN111981705AShorten the timeAvoid long-term exposureSolar heating energySolar heat storageMechanical engineeringPhysics

The invention discloses a trough type photo-thermal power generation system. The trough type photo-thermal power generation system comprises a plurality of rows of heat collecting plates, a supportingrod is arranged on each row of heat collecting plates, connectors are arranged on the supporting rods, protective pipes penetrate through the connectors, each protective pipe is provided with a cleaning mechanism, each cleaning mechanism comprises a shell, an arc-shaped cavity is formed in a fixing plate, the two ends of each arc-shaped cavity are open, two movable plates are arranged at the twoends of the arc-shaped cavity in a sliding mode, follow-up plates are arranged at the ends of the movable plates, a clamping plate I is arranged on the inner side wall of one flange, a clamping plateII is fixed to the inner side wall of the other flange, a cleaning assembly I is arranged on the inner side wall of the clamping plate I, and a cleaning assembly II is arranged on the inner side wallof the clamping plate II. According to the trough type photo-thermal power generation system, the tedious steps of traditional manual cleaning are omitted, the outer walls of the protective pipes on arow of heat collection plates are cleaned and dedusted at a time, the shutdown maintenance time of an existing photo-thermal power generation system is shortened, operators can be prevented from being exposed to the heat radiation environment for a long time, and the probability of safety accidents is reduced.

Owner:胜利油田胜兴集团有限责任公司

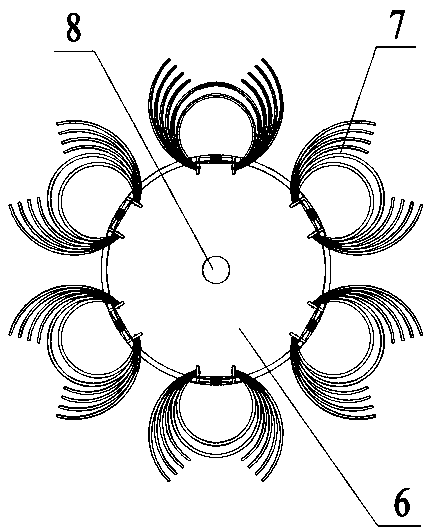

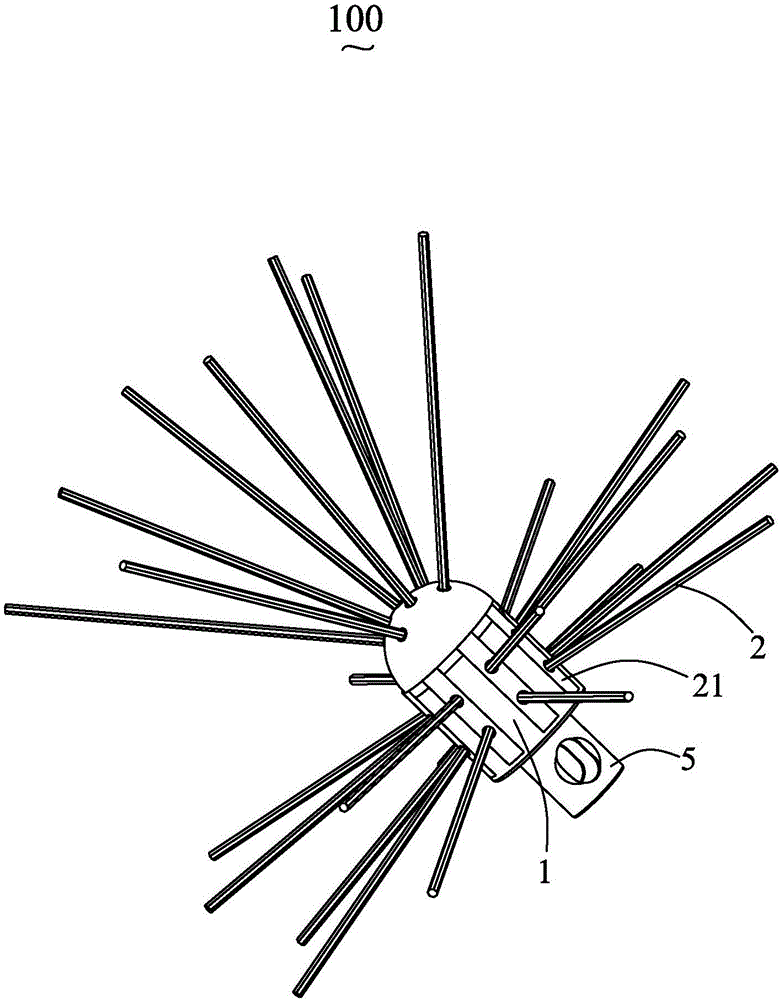

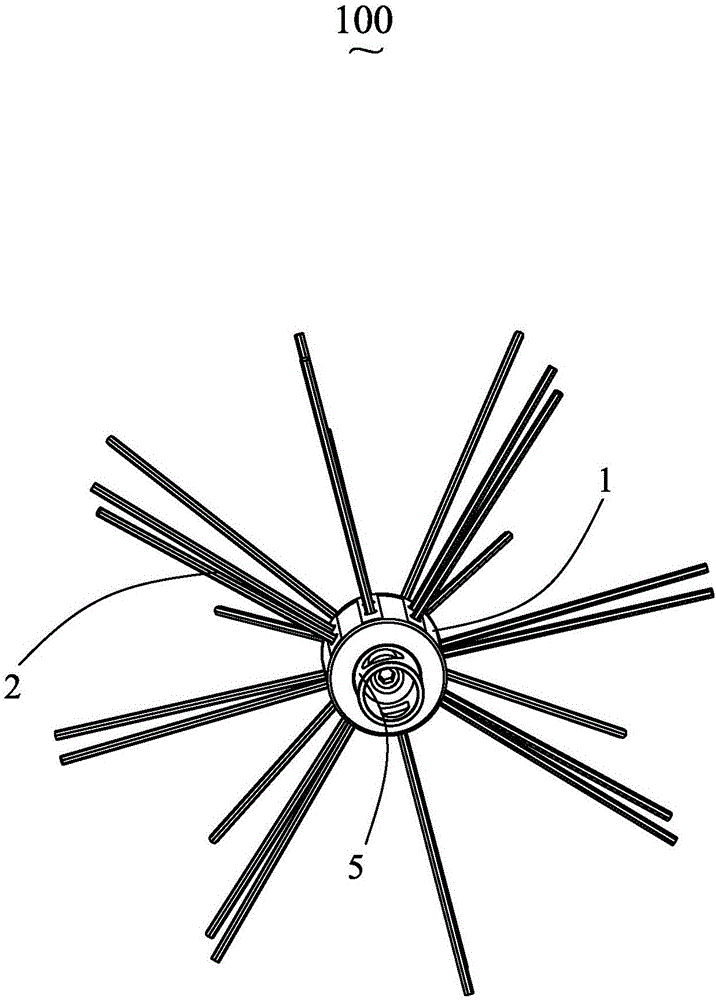

Fireplace pipeline cleaning brush with circular cover

ActiveCN106765236AAll-round cleaning without dead endsNo dead angle cleaningSolid removalEngineeringFireplace

The invention discloses a fireplace pipeline cleaning brush with a circular cover, comprising a cylindrical plastic body and nylon ropes fixedly held on the plastic body; the fireplace pipeline cleaning brush is characterized in that the plastic body is provided with a first end, a second end, and a peripheral wall situated between the first wall and the second wall; the first end is encircled to be a through hole, and the second end is encircled to be a round ring; several buckle holes extended from the first end to the second end are arranged on the peripheral wall; the fireplace pipeline cleaning brush with the circular cover is further provided with a buckle block installed in the buckle hole, the nylon ropes are arranged on the buckle block; the fireplace pipeline cleaning brush with the round cover is further provided with the round cover installed on the first end of the plastic body; several nylon ropes are arranged on the circular cover. Through arranging the nylon ropes on the circular cover, the nylon rope can clean the fireplace pipeline completely without dead corner.

Owner:池州海琳服装有限公司

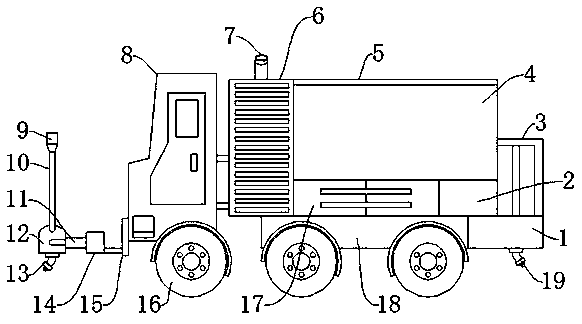

Cleaning vehicle for solar panel

InactiveCN111185453ATake advantage ofReasonable structural designFlexible article cleaningCleaning using liquidsEngineeringStructural engineering

The invention discloses a cleaning vehicle for a solar panel. The cleaning vehicle comprises a water tank. An installing plate is arranged on the upper side of the water tank. The solar panel is installed on the top of the installing plate. A driving machine case is arranged on the lower side of the water tank. An installing base is arranged on the lower side of the driving machine case. Walking wheels are arranged on the lower side of the installing base. A walking frame is arranged at the rear end of the installing base. A tail jet is arranged at the bottom of the walking frame. A high-pressure pump is arranged at the front end of a guardrail. The cleaning vehicle is reasonable in structural design, sufficiently utilizes the space, and is low in use difficulty and convenient to install;nozzles are arranged at the front end and the rear end of the cleaning vehicle and used for cleaning the solar panel, the duplex cleaning is realized, the cleaning effect is good, and no dead cornersexist during cleaning; and an alarm is given in the cleaning process, the probability that sewage produced in cleaning is splashed onto pedestrians can be reduced, the jet width of the device is fixed, and the solar panel can be concentratedly cleaned by high-pressure sprayed water.

Owner:XIAN XINGUIXI INFORMATION TECH CO LTD

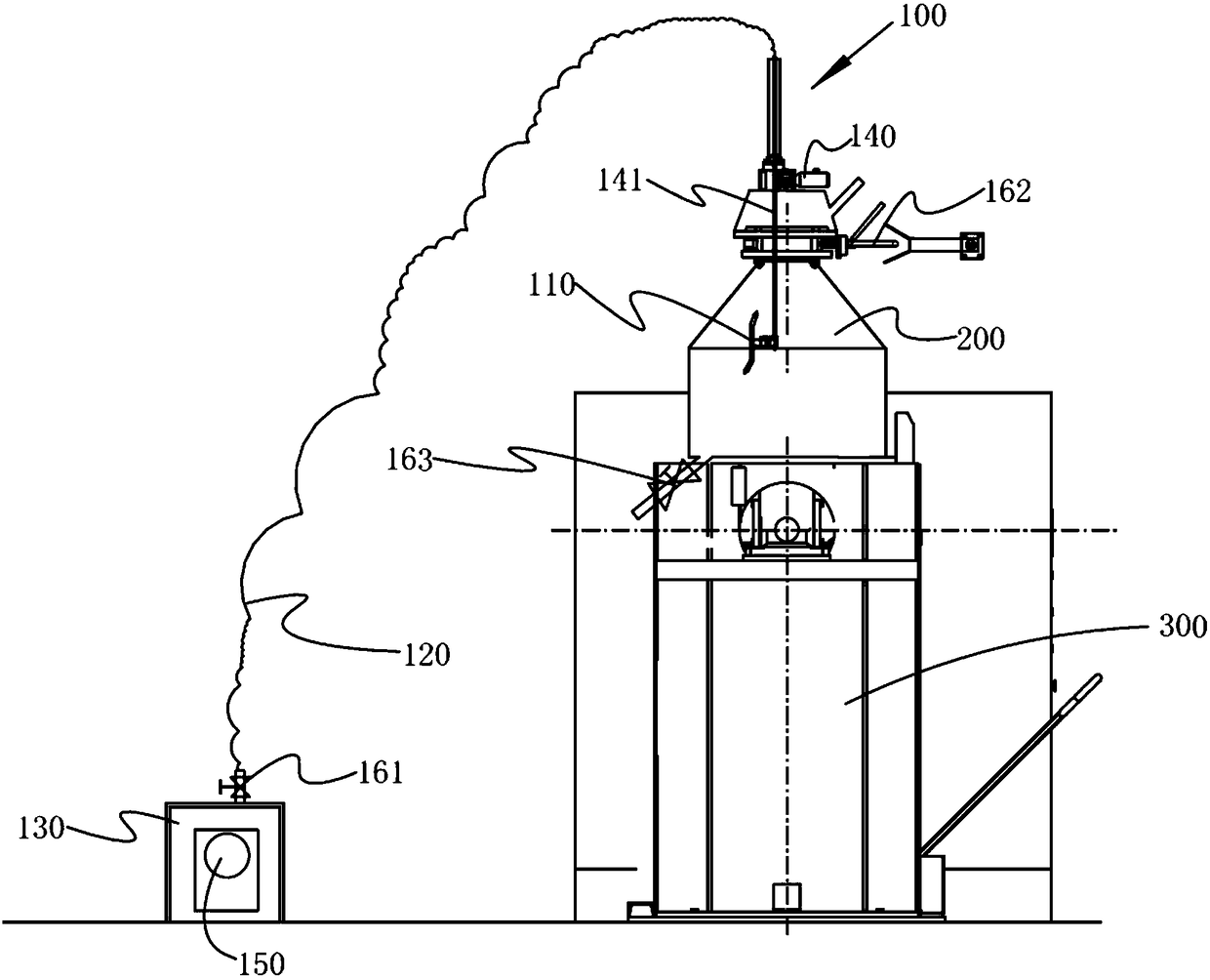

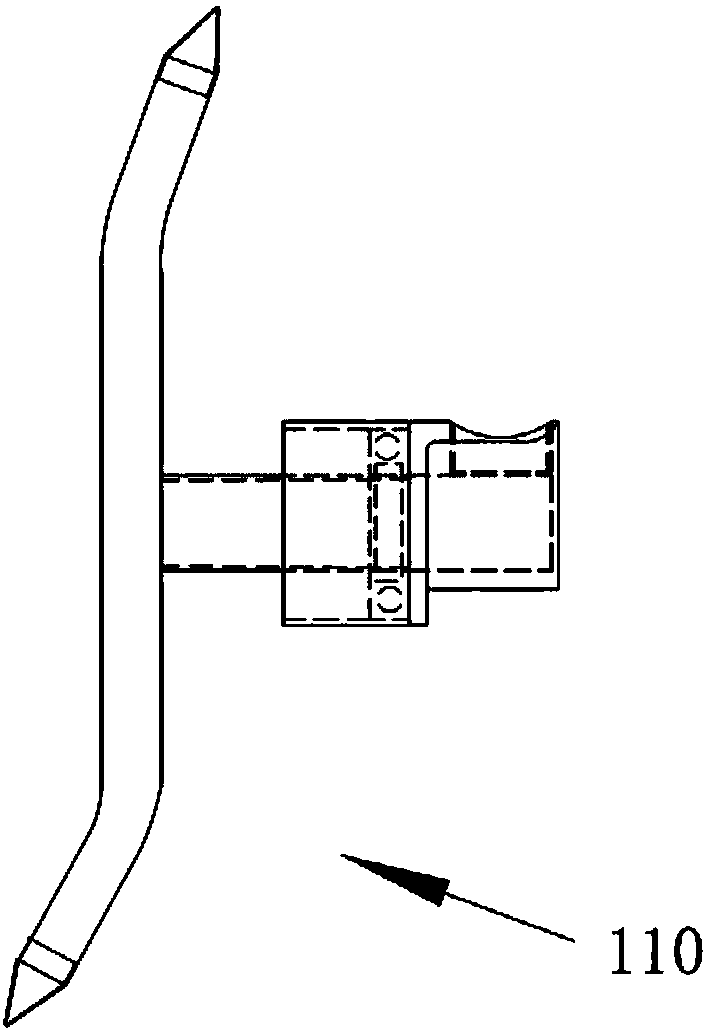

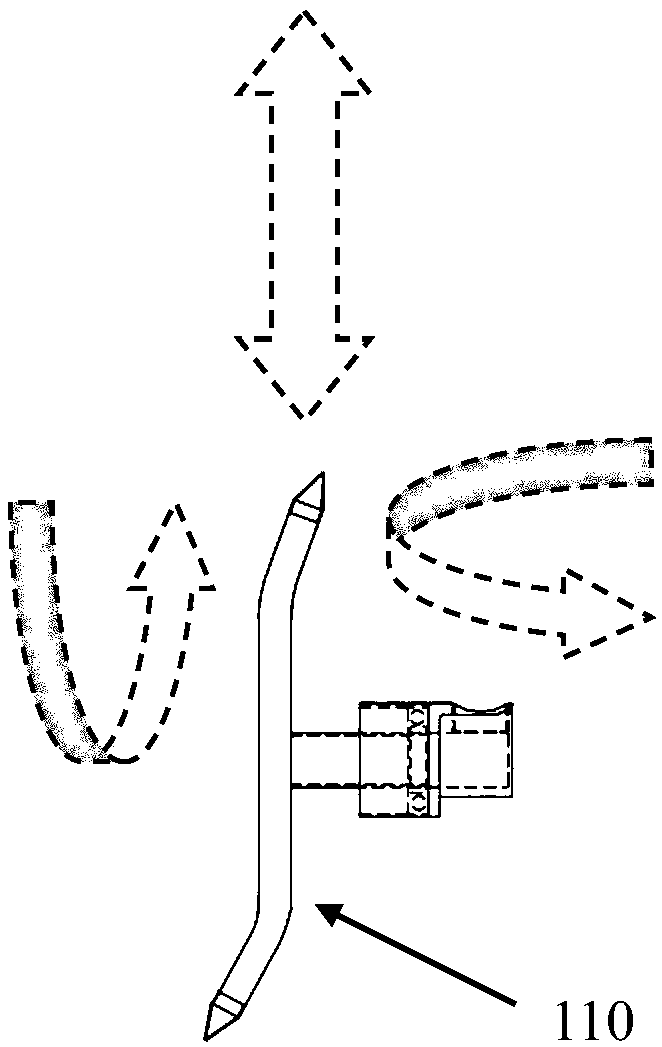

Automatic cleaning system of mixing equipment and application

PendingCN108393034AExpanded automatic movement angleNo dead angle cleaningTransportation and packagingHollow article cleaningEngineeringElectrical and Electronics engineering

The invention discloses an automatic cleaning system of mixing equipment and application. The automatic cleaning system comprises an automatic cleaning tool, wherein the automatic cleaning tool comprises a cleaning head which is communicated with a cleaning medium conveying pipeline; the cleaning head is in transmission connection with a transmission device; the cleaning head does multi-angle motion along the transmission device. By adopting the automatic cleaning system disclosed by the invention, high-precision automatic cleaning of the mixing equipment is realized; the automatic cleaning system is simple in structure and easy to operate, is suitable for being applied to cleaning of the mixing equipment in various fields and is especially suitable for cleaning the mixing equipment whichhas great washing difficulties, large volume and relatively high container depth.

Owner:TIGER NEW SURFACE MATERIALS QINGYUAN CO LTD

Drawer-type dish washer internally equipped with water pipes

PendingCN108670155AImprove positionIncrease the angleTableware washing/rinsing machine detailsHome appliance efficiency improvementEngineeringWater spray

The invention relates to the technical field of dish washers, in particular to a drawer-type dish washer. The drawer-type dish washer internally equipped with the water pipes comprises a housing. A cover plate is arranged on the housing. A movable drawer is arranged on the housing. The cover plate is equipped with a top spray arm having water spray holes. A circulating water pump is installed on the bottom surface of the drawer. The circulating water pump communicates with the top spray arm through a top spray water inlet pipe. The top spray water inlet pipe can move as the drawer moves. The top spray water inlet pipe is arranged in the interior of the drawer. Additionally, the invention further provides the drawer-type dish washer having upper and lower spray arms. The drawer-type dish washer internally equipped with the water pipes has the following beneficial effects of great cleaning force and no cleaning dead corners.

Owner:VATTI CORP LTD

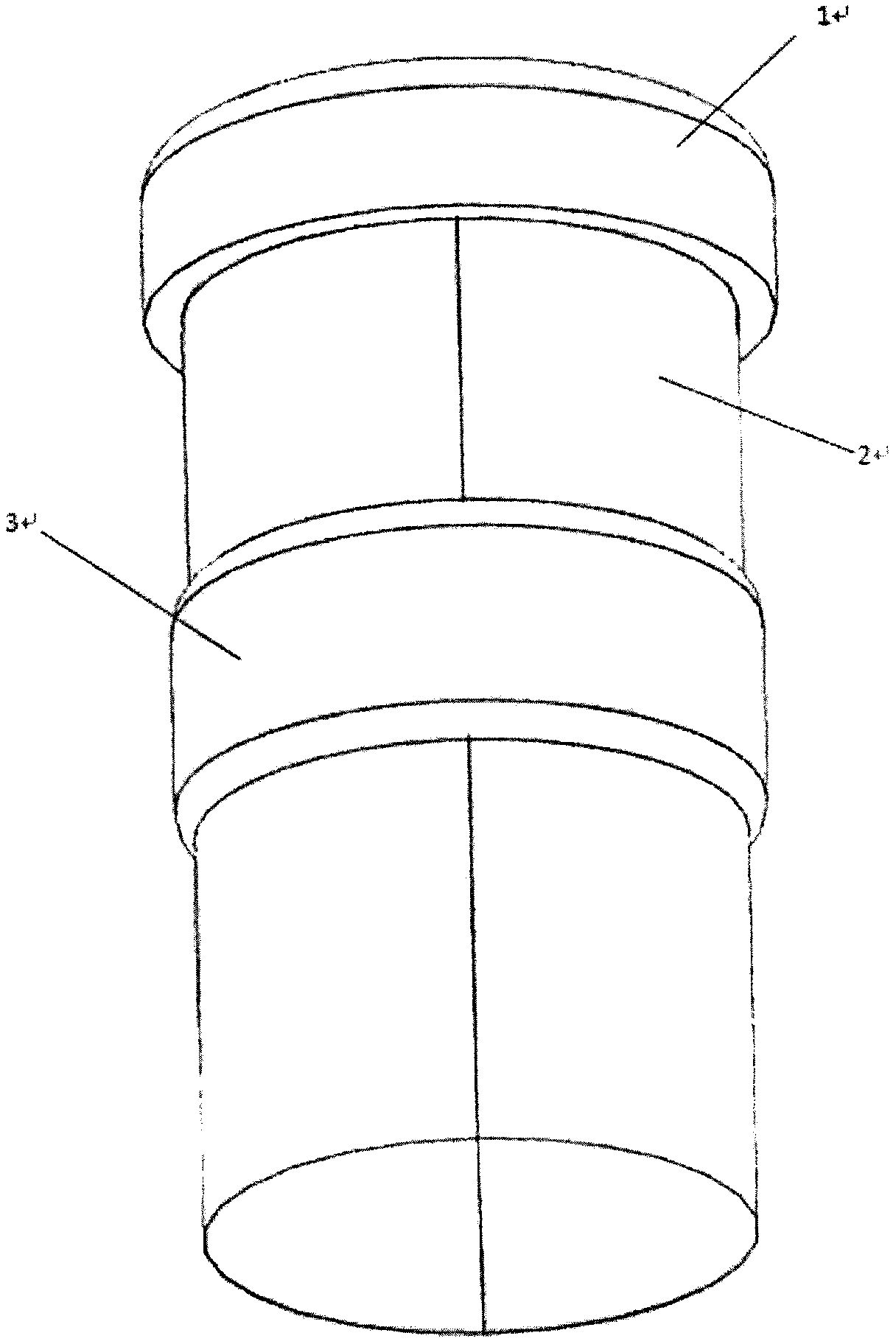

Teacup convenient for cleaning

The invention provides a teacup convenient for cleaning, which comprises a cup cover, a cup body and an elastic hoop. The teacup convenient for cleaning is characterized in that the cup body is formedby combining a left cup body and a right cup body; the upper end of the left cup body is provided with a thread matched with the cup cover, and a section buckled with the right cup body along a central axis is provided with a concave buckle; the upper end of the right cup body is provided with the thread matched with the cup cover, and the section buckled with the left cup body along the centralaxis is provided with a convex buckle; the left cup body and the right cup body are buckled to form a cylindrical structure with an open upper end and a closed bottom; the elastic loop is the cylindrical shape with openings at two ends, an inner diameter of the elastic hoop is slightly smaller than an outer diameter of the cup body, and the left cup body and the right cup body are tightly buckledtogether under an action of an elasticity of the elastic hoop. The tea cup convenient for cleaning is reasonable in structure, convenient to decompose and combine, and free of dead corners when cleaning the teacup.

Owner:YANGZHOU POLYTECHNIC INST

A special equipment for side pressure high-rise glass curtain wall cleaning

InactiveCN109303515BThere is no disadvantage of halfway chargingReduce loadCarpet cleanersFloor cleanersElectric machineBrush

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com