Bucket type Z-type conveyor

A conveyor and bucket-type technology, applied in the field of bucket-type Z-type conveyors, can solve the problems of poor airtightness, human injury, and high production costs, and achieve flexible equipment installation and layout, convenient installation and disassembly, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0021] The problem to be solved by the present invention is to provide a bucket type Z-type conveyor with high efficiency, energy saving, strong adjustability, and effectively reducing problems such as spillage during material transportation.

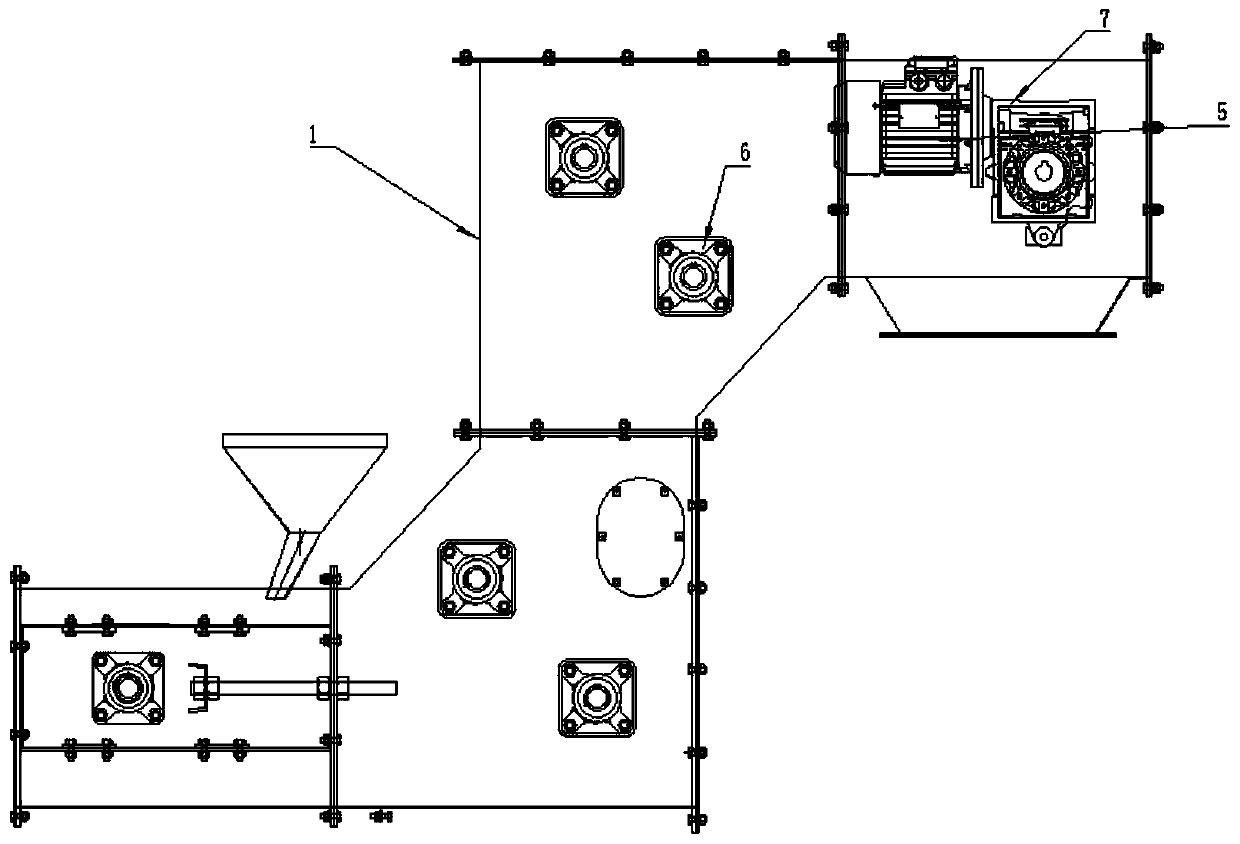

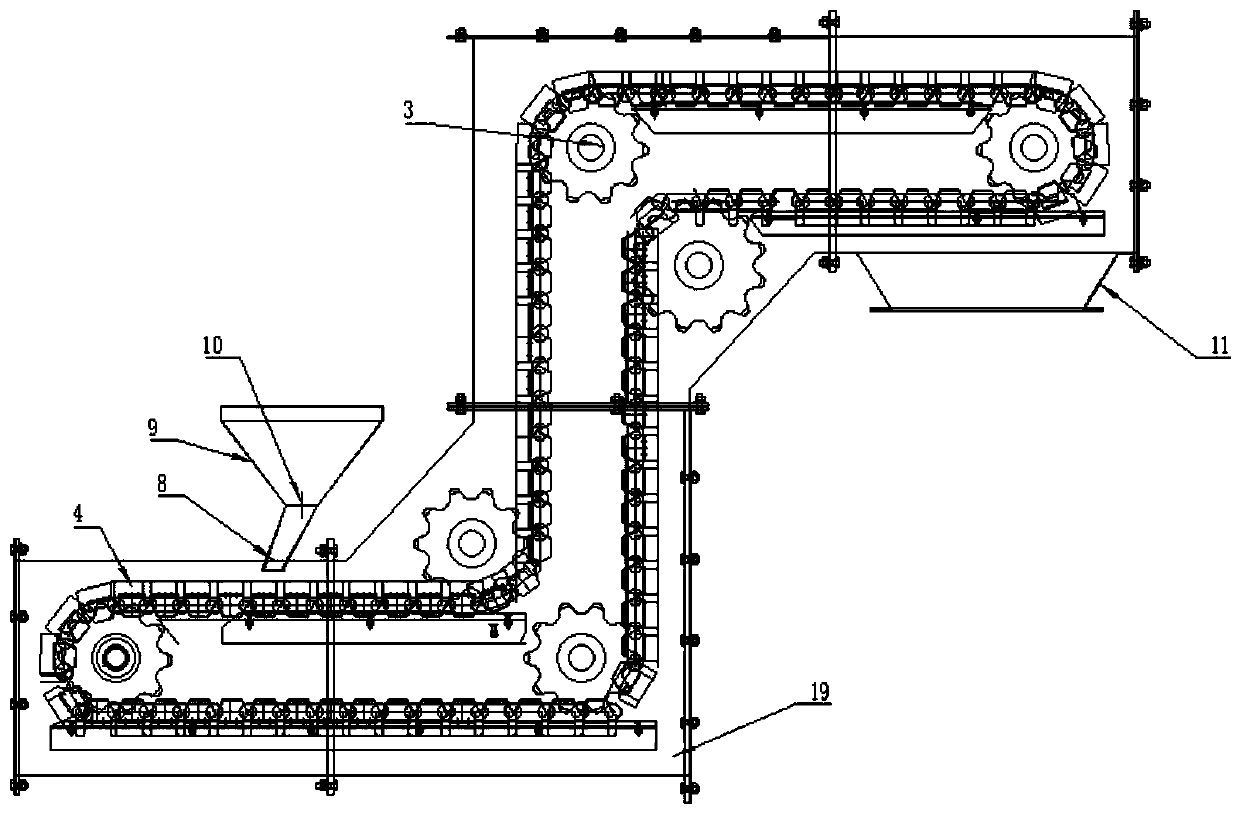

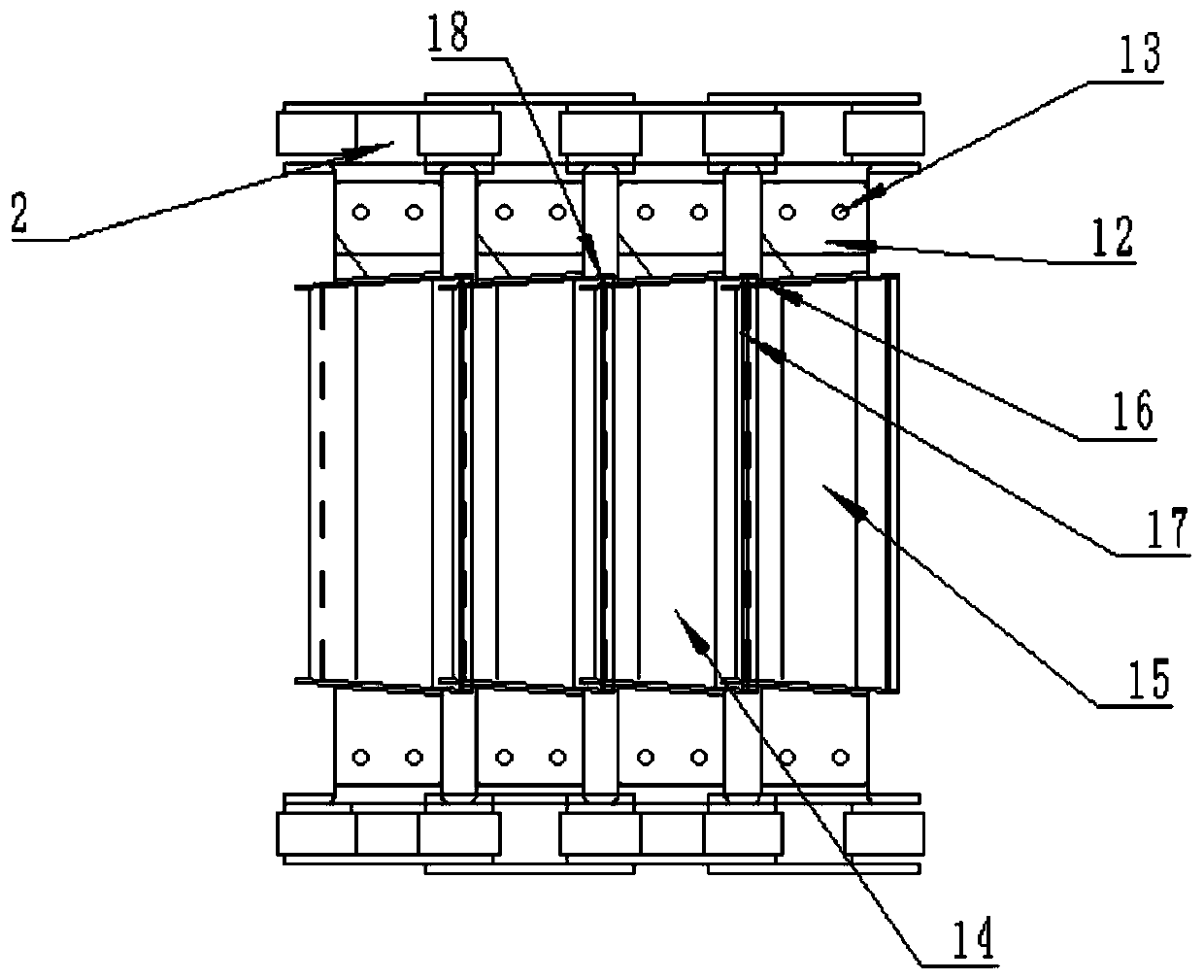

[0022] Such as figure 1 , figure 2 As shown, in order to ensure stable operation and high work efficiency during use, the present invention relates to a bucket type Z-type conveyor, including:

[0023] Housing 1, transmission chain 2, sprocket 3, hopper 4, motor 5;

[0024] The housing 1 is provided with a sprocket fixing device 6; the sprocket 3 is fixed inside the housing 1 through the sprocket fixing device 6; the transmission chain 2 is connected with the sprocket 3; The sprocket 3 is symmetrically arranged left and right in the housing 1; the hopper 4 is connected and fixed with the transmission chain 2; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com