Automatic cleaning system of mixing equipment and application

A technology for automatic cleaning and mixing equipment, applied in cleaning methods and utensils, mixers, cleaning hollow objects, etc., can solve the problems of inability to meet the cleaning requirements of mixing equipment, secondary pollution of waste liquid, and safety of personnel operations. The effect of expanding the automatic movement angle, no dead angle cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

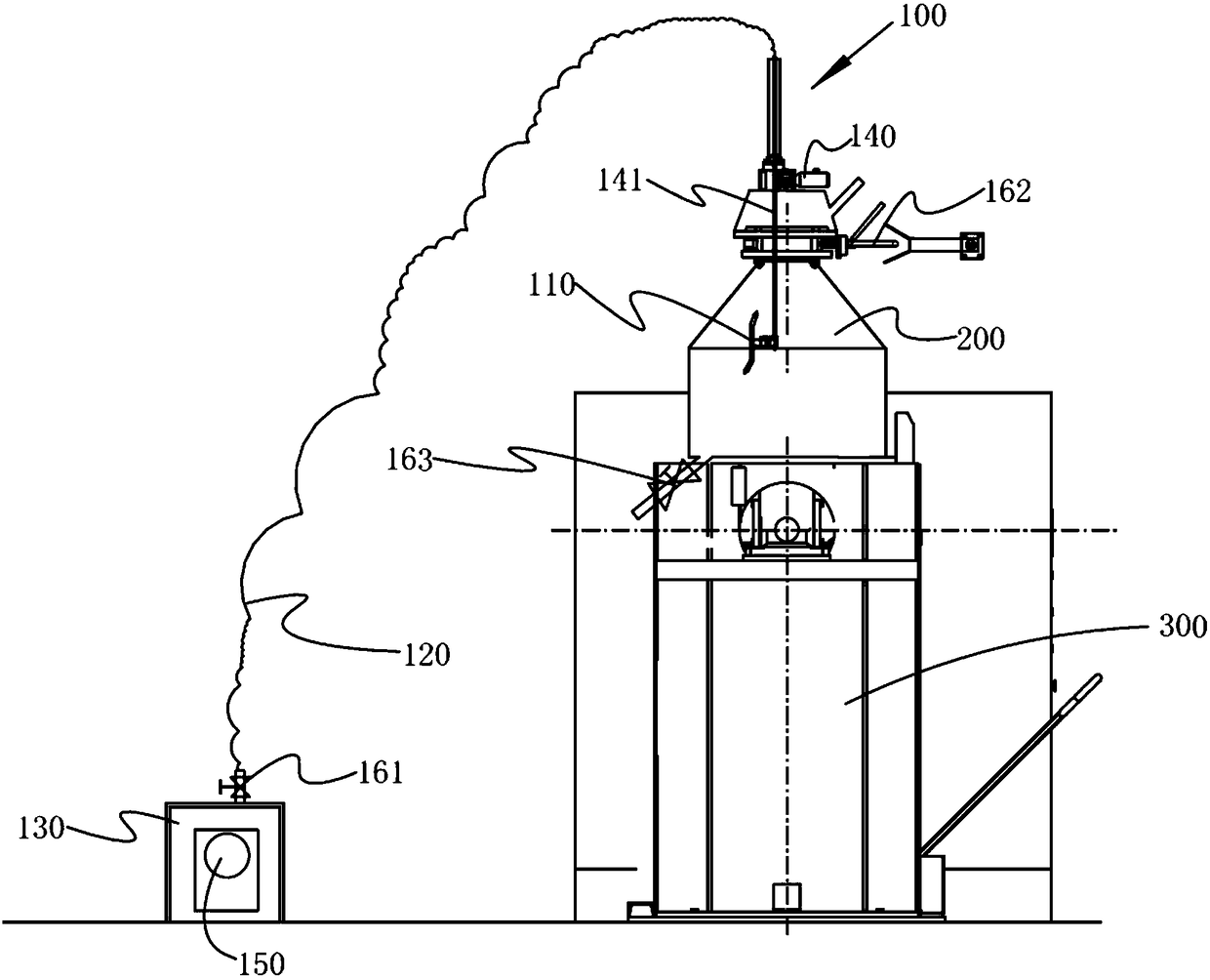

[0035] See figure 1 An automatic cleaning system 100 for mixing equipment is shown, which is used for cleaning the mixing equipment for powder coatings. Specifically, in this embodiment, the mixing equipment for powder coatings is a split structure, including a mixing container 200 and mixer 300;

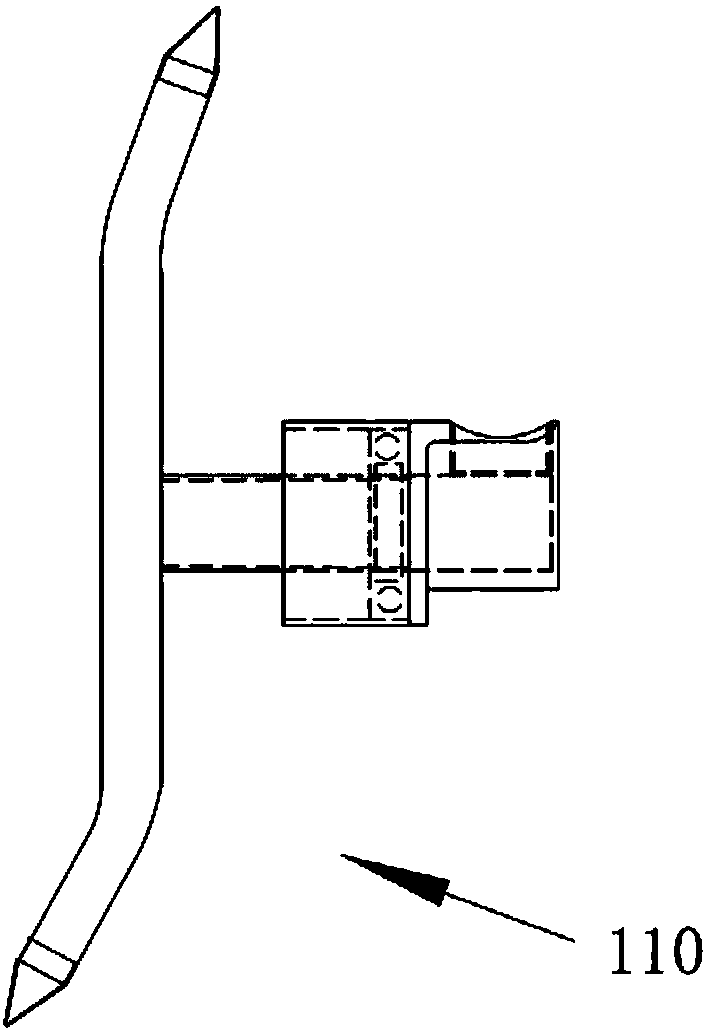

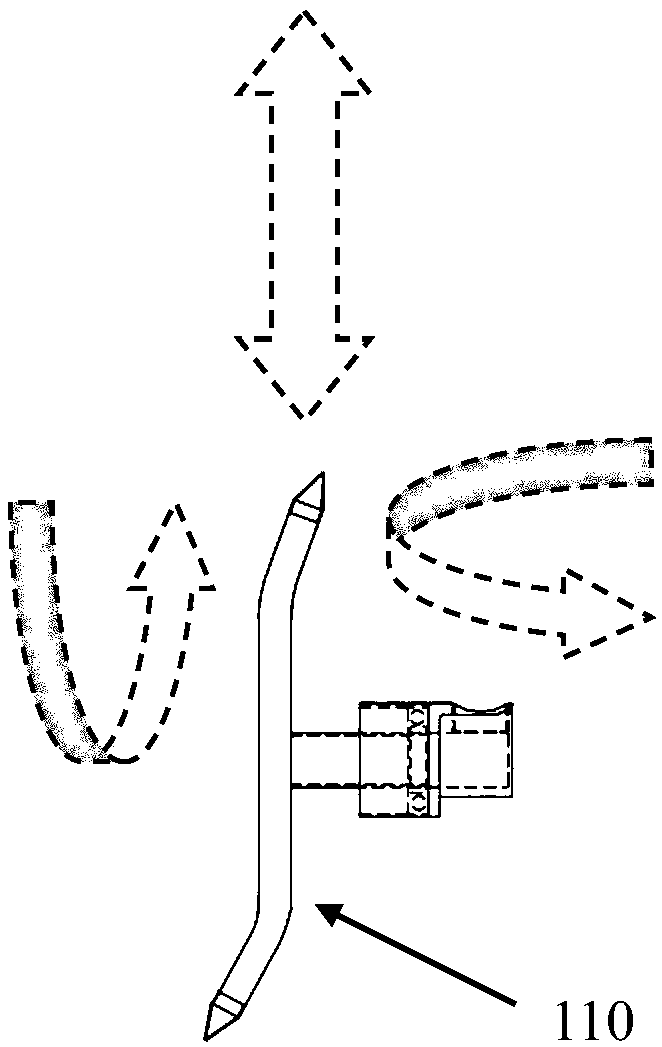

[0036] In this embodiment, the automatic cleaning system 100 includes an automatic cleaning tool, wherein the automatic cleaning tool includes a cleaning head 110 communicated with a cleaning medium delivery pipeline 120, and the cleaning head 110 is connected to a cleaning medium delivery source 130 through the cleaning medium delivery pipeline 120, Wherein, the cleaning medium is gas or liquid; and the cleaning head 110 is in transmission connection with the transmission device 140; specifically, in this embodiment, the cleaning medium is compressed air or nitrogen, and in other embodiments, of course, water and cleaning agent can also be used As the cleaning medium of the presen...

Embodiment 2

[0048] An application of an automatic cleaning system for mixing equipment, the remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the only difference is that in this embodiment, please refer to Figure 4 As shown, the powder coating mixing equipment 200' has an integrated structure, which can also achieve the same or similar technical effects as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com