Dish-washing machine

A dishwasher and machine technology, which is applied to the washing machine/washing machine of tableware, cleaning equipment, household utensils, etc., can solve the problems of slow washing of dishes and low efficiency, and achieve good washing ability, small installation space, and structure. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

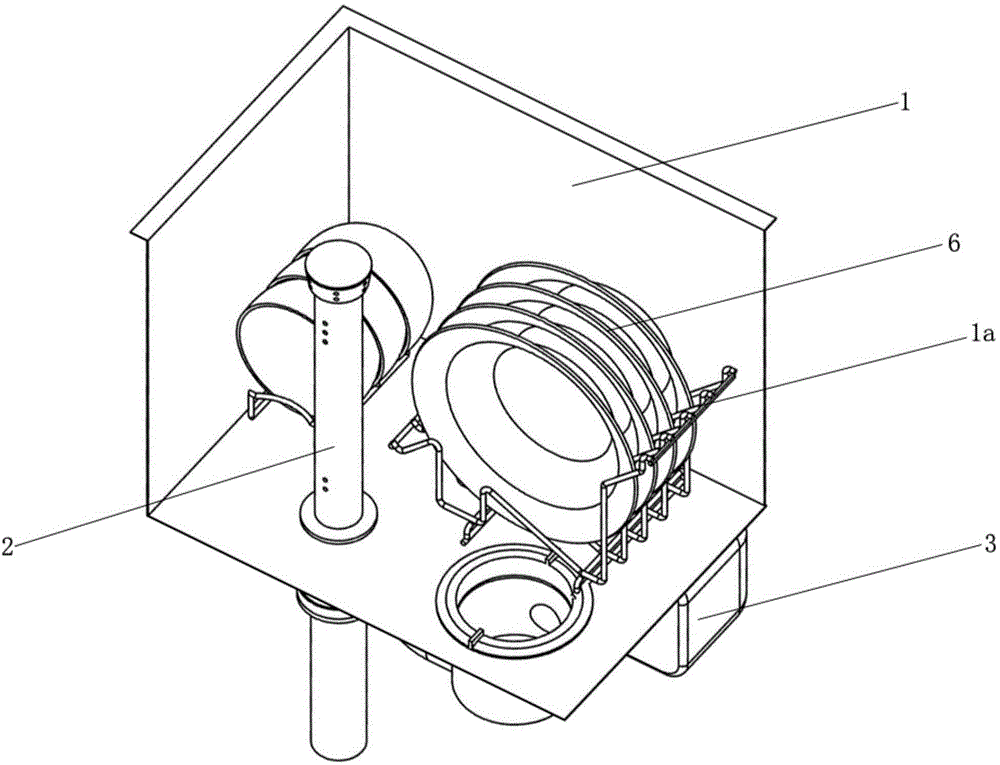

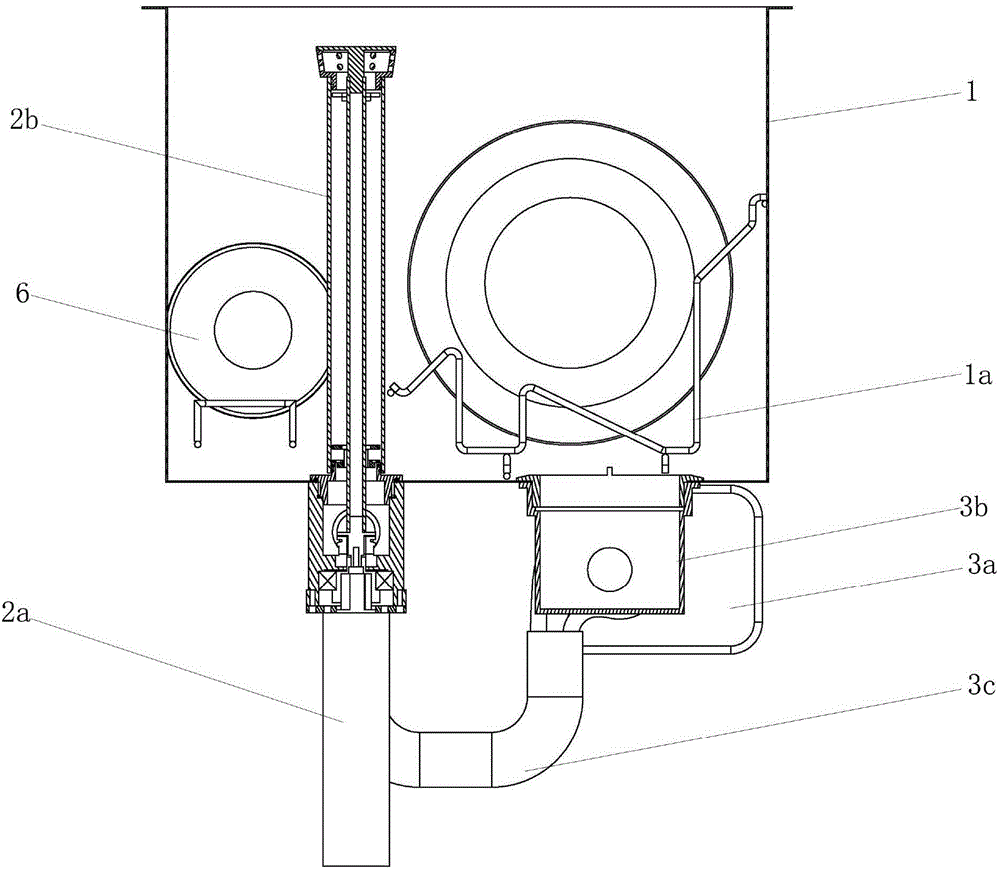

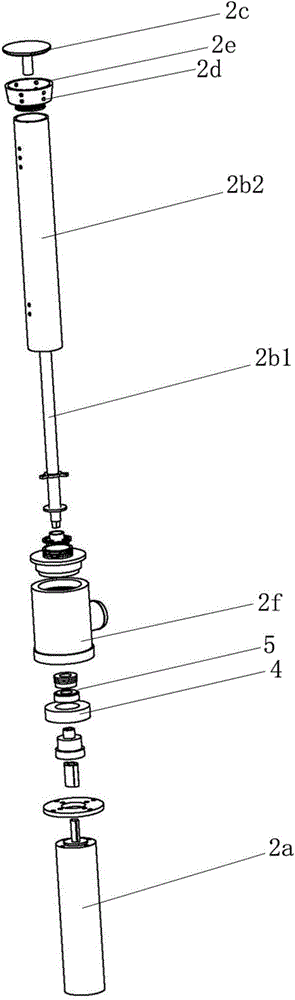

[0020] Refer to attached Figure 1~4 , a kind of dishwasher, the dishwasher comprises a body 1, a spray device 2 and a circulation device 3, wherein the body 1 is a box structure, the inner chamber of the body 1 is a sink for washing dishes, the body 1 The bottom of the inner cavity is provided with a dish rack 1a for placing the dishes 6 to be cleaned; the spray device 2 includes a motor 2a, a spray pipe 2b, a gland 2c and a fixing seat 2f, and the spray pipe 2b located in the body 1 It is located above the motor 2a and rotates under the drive of the motor 2a; the spray pipe 2b includes an inner pipe 2b1 and an outer pipe 2b2, the outer pipe 2b2 is sleeved outside the inner pipe 2b1, the inner pipe 2b1 is connected with the shaft of the motor 2a, and the outer pipe 2b2 The outer surface is provided with spray holes 2d arranged longitudinally, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com